In the field of modern industrial manufacturing, handheld piezoelectric ultrasonic spot welding machines are gradually becoming an indispensable welding tool in many industries due to their efficient, accurate, and environmentally friendly characteristics. This article will provide a detailed introduction to the structure, working principle, advantages, and application scenarios of handheld piezoelectric ultrasonic spot welding machines, taking you to appreciate their widespread application and outstanding performance in modern industry.

In the field of modern industrial manufacturing, handheld piezoelectric ultrasonic spot welding machines are gradually becoming an indispensable welding tool in many industries due to their efficient, accurate, and environmentally friendly characteristics. This article will provide a detailed introduction to the structure, working principle, advantages, and application scenarios of handheld piezoelectric ultrasonic spot welding machines, taking you to appreciate their widespread application and outstanding performance in modern industry.

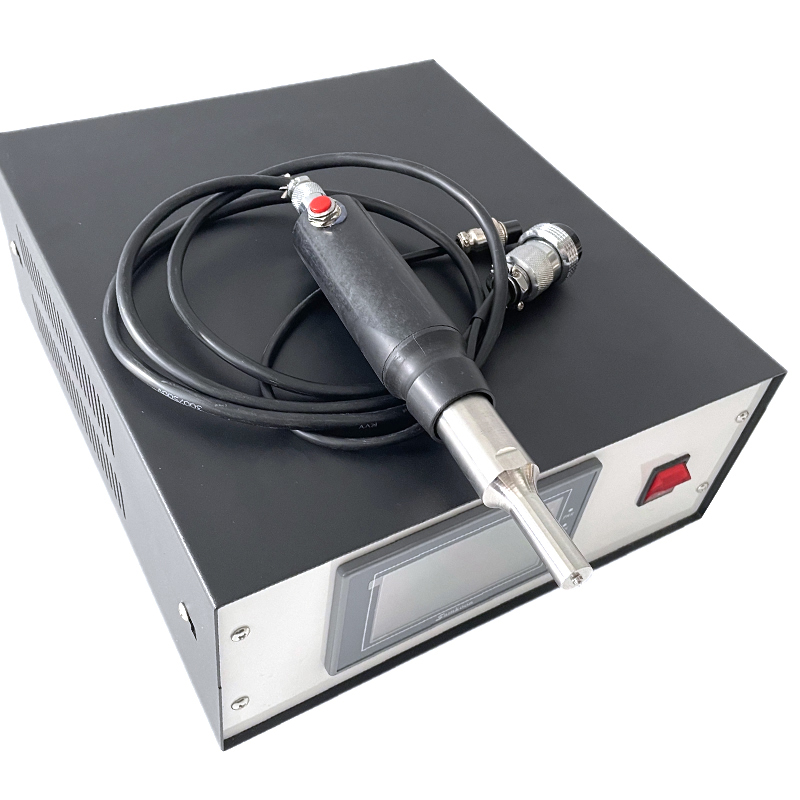

It mainly consists of core components such as piezoelectric ceramic crystal, ultrasonic generator, transducer, welding head, controller, etc. Among them, piezoelectric ceramic crystal vibration serves as the vibration source, generating high-frequency electrical energy through an ultrasonic generator. The electrical energy is converted into ultrasonic vibration through a transducer, and finally the vibration energy is transmitted to the joint of the workpiece to be welded by the welding head.

| Type | Power(W) | Frequency (KHz) |

| PLS-DHJ-300 | 300W | 15KHz/20khz/28khz/40khz |

| PLS-DHJ-500 | 500W | 15KHz/20khz/28khz/40khz |

| PLS-DHJ-800 | 800W | 15KHz/20khz/28khz/40khz |

| PLS-DHJ-900 | 900W | 15KHz/20khz |

| PLS-DHJ-1000 | 1000W |

15KHz/20khz |

Ultrasonic Transducer,Ultrasonic Generator,Ultrasonic Cleaner -SKSONIC

Ultrasonic Transducer,Ultrasonic Generator,Ultrasonic Cleaner -SKSONIC