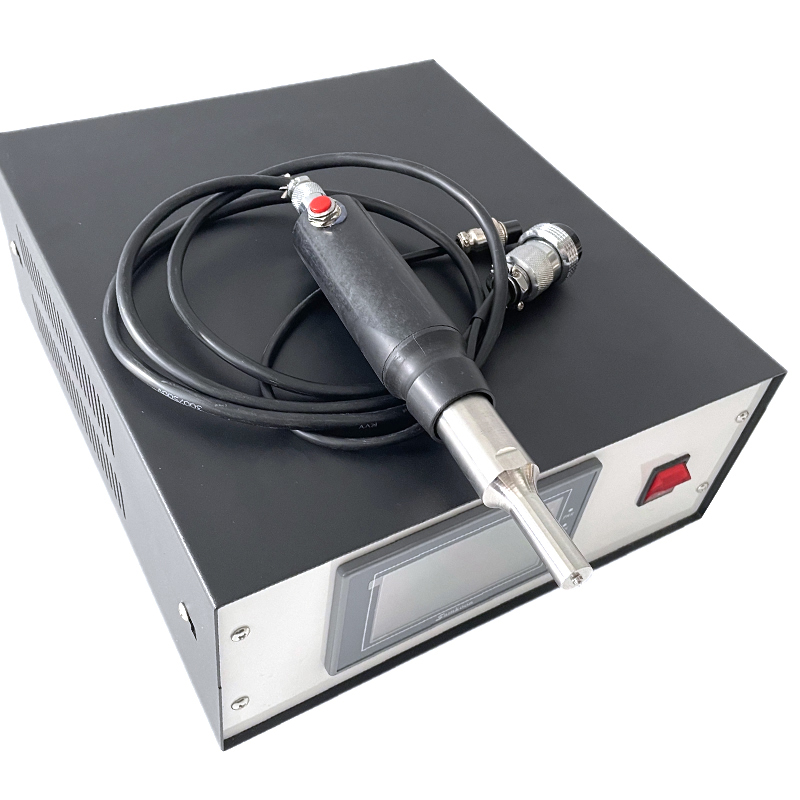

The use of handheld industrial ultrasonic plastic spot welding machines greatly improves production efficiency in industrial production. Workers can perform welding operations anytime and anywhere without the need for a fixed workplace, greatly saving time and labor costs. Meanwhile, due to its simple operation, workers only need to undergo simple training to become proficient, reducing the requirement for professional skills.

The use of handheld industrial ultrasonic plastic spot welding machines greatly improves production efficiency in industrial production. Workers can perform welding operations anytime and anywhere without the need for a fixed workplace, greatly saving time and labor costs. Meanwhile, due to its simple operation, workers only need to undergo simple training to become proficient, reducing the requirement for professional skills.

This ultrasonic plastic spot welding machine also has good adaptability. It can be used for welding plastic parts of different materials and thicknesses, meeting different production needs. Its presence can be found in fields such as automotive components, electronic device casings, and medical devices. The handheld industrial ultrasonic plastic spot welding machine has demonstrated strong competitiveness in the field of plastic welding due to its high efficiency, portability, and ease of operation. Its emergence not only improves production efficiency and reduces production costs, but also provides strong support for the innovative development of industrial production. With the continuous progress of technology, we believe that this device will have even broader application prospects in the future.

| Type | Power(W) | Frequency (KHz) |

| PLS-DHJ-300 | 300W | 15KHz/20khz/28khz/40khz |

| PLS-DHJ-500 | 500W | 15KHz/20khz/28khz/40khz |

| PLS-DHJ-800 | 800W | 15KHz/20khz/28khz/40khz |

| PLS-DHJ-900 | 900W | 15KHz/20khz |

| PLS-DHJ-1000 | 1000W |

15KHz/20khz |

Ultrasonic Transducer,Ultrasonic Generator,Ultrasonic Cleaner -SKSONIC

Ultrasonic Transducer,Ultrasonic Generator,Ultrasonic Cleaner -SKSONIC