During the welding process, the welding head applies ultrasonic vibration energy to the surface of the workpiece, generating heat energy through friction, causing the surface of the workpiece to melt and quickly bond. Due to the fact that ultrasonic welding is a solid-state welding method that does not require the addition of any auxiliary materials during the welding process, it has the advantages of environmental protection and pollution-free.

During the welding process, the welding head applies ultrasonic vibration energy to the surface of the workpiece, generating heat energy through friction, causing the surface of the workpiece to melt and quickly bond. Due to the fact that ultrasonic welding is a solid-state welding method that does not require the addition of any auxiliary materials during the welding process, it has the advantages of environmental protection and pollution-free.

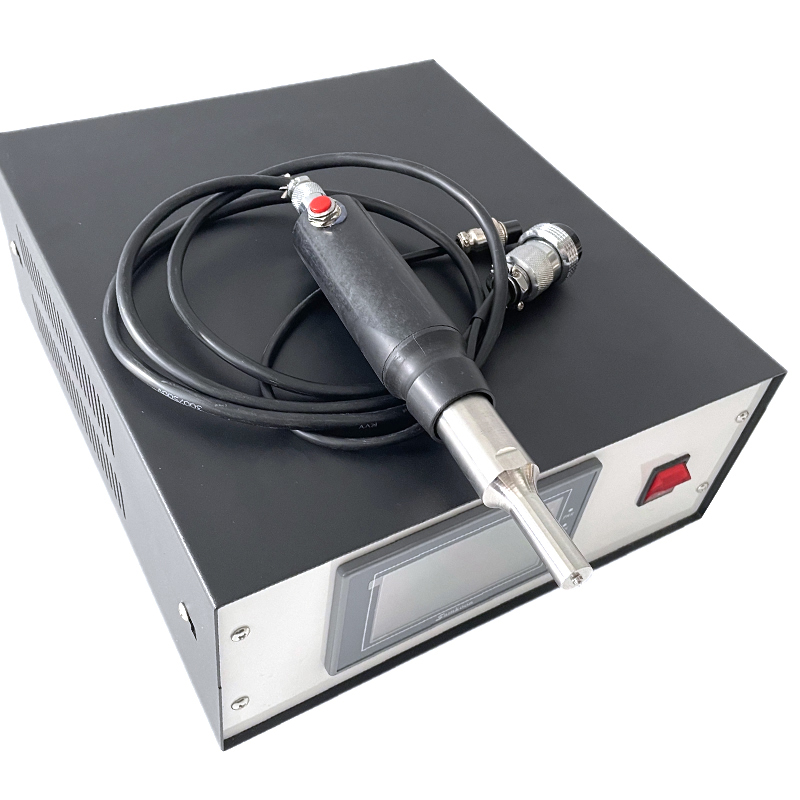

Compared to traditional welding methods, handheld piezoelectric ultrasonic spot welding machines have many significant advantages. Firstly, its welding speed is fast, and the welding time is usually less than 1 second, greatly improving production efficiency. Secondly, the welding quality is stable and reliable, with beautiful and firm welds that can meet the welding needs of various complex shapes. In addition, since there is no need to add solder or flux during the ultrasonic welding process, it avoids the pollution problem caused by solder residue and has the characteristics of environmental protection and energy conservation.

| Type | Power(W) | Frequency (KHz) |

| PLS-DHJ-300 | 300W | 15KHz/20khz/28khz/40khz |

| PLS-DHJ-500 | 500W | 15KHz/20khz/28khz/40khz |

| PLS-DHJ-800 | 800W | 15KHz/20khz/28khz/40khz |

| PLS-DHJ-900 | 900W | 15KHz/20khz |

| PLS-DHJ-1000 | 1000W |

15KHz/20khz |

Ultrasonic Transducer,Ultrasonic Generator,Ultrasonic Cleaner -SKSONIC

Ultrasonic Transducer,Ultrasonic Generator,Ultrasonic Cleaner -SKSONIC