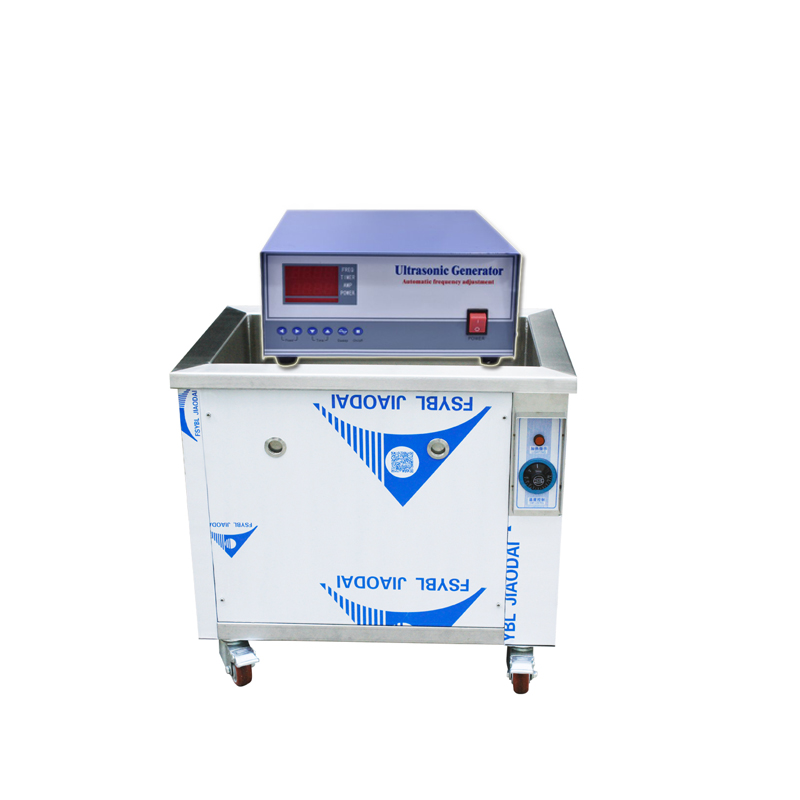

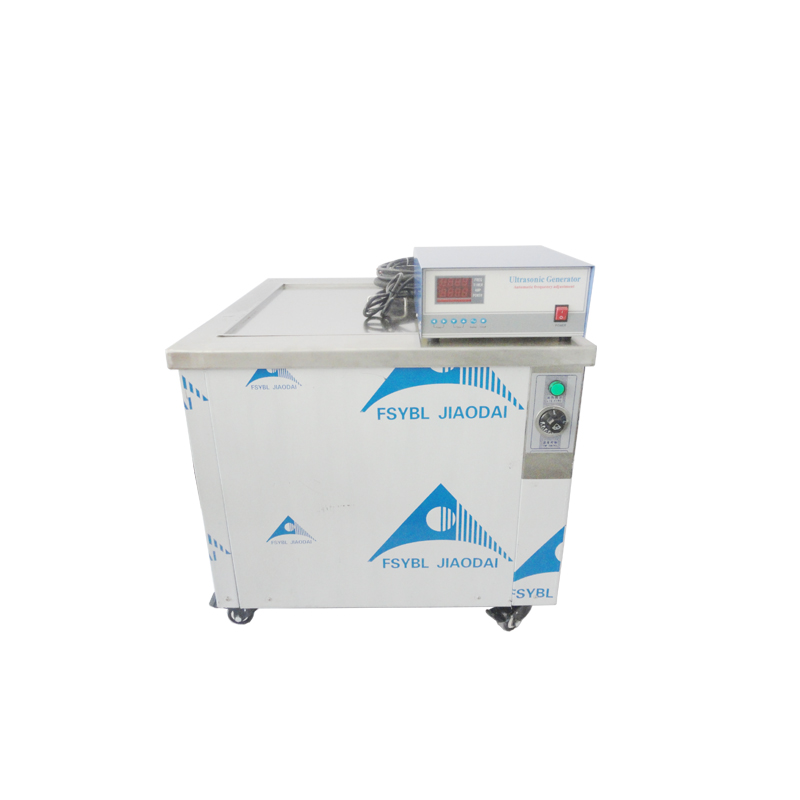

The ultrasonic cleaning machine mainly consists of three parts: ultrasonic power supply! The function of ultrasonic power supply is to provide ultrasonic frequency electrical energy to the transducer. The transducer converts electrical energy into mechanical vibration, i.e. sound energy. The cleaning tank is used to hold cleaning fluid and the cleaned workpiece. The cleaning tank is usually made of stainless steel plate, Transducers are generally installed at the bottom of the cleaning tank or on the side wall of the tank or in a sealed stainless steel box. The ultrasonic wound cleaning machine designed by the company adopts a non immersion method, and the amplitude converter sprays atomized cleaning solution for wound cleaning, which has the advantages of avoiding infection, wide application range, and simple operation

The ultrasonic cleaning machine mainly consists of three parts: ultrasonic power supply! The function of ultrasonic power supply is to provide ultrasonic frequency electrical energy to the transducer. The transducer converts electrical energy into mechanical vibration, i.e. sound energy. The cleaning tank is used to hold cleaning fluid and the cleaned workpiece. The cleaning tank is usually made of stainless steel plate, Transducers are generally installed at the bottom of the cleaning tank or on the side wall of the tank or in a sealed stainless steel box. The ultrasonic wound cleaning machine designed by the company adopts a non immersion method, and the amplitude converter sprays atomized cleaning solution for wound cleaning, which has the advantages of avoiding infection, wide application range, and simple operation

| Type | Internal size L*W*H (mm) |

Frequency (Khz) | Power(W) | Heating(W) |

| PU-1006TT | 280×210×210 | 20,28,33,40,80,130 | 300 | 1000 |

| PU-1012TT | 400×310×280 | 20,28,33,40,80,130 | 600 | 3000 |

| PU-1018TT | 490×360×320 | 20,28,33,40,80,130 | 900 | 3000 |

| PU-1024TT | 630×430×320 | 20,28,33,40,80,130 | 1200 | 4000 |

| PU-1030TT | 630×530×320 | 20,28,33,40,80,130 | 1500 | 4000 |

| PU-1036TT | 680×530×360 | 20,28,33,40,80,130 | 1800 | 5000 |

| PU-1040TT | 680×570×400 | 20,28,33,40,80,130 | 2000 | 5000 |

| PU-1041TT | 730×570×450 | 20,28,33,40,80,130 | 2400 | 6000 |

| PU-1042TT | 790×670×510 | 20,28,33,40,80,130 | 3000 | 6000 |

| PU-1043TT | 850×770×570 | 20,28,33,40,80,130 | 4000 | 7000 |

| PU-1044ST | 910×820×620 | 20,28,33,40,80,130 | 5000 | 7000 |

| PU-1045TT | 960×870×680 | 20,28,33,40,80,130 | 8000 | 8000 |

| PU-1046TT | 1100×930×730 | 20,28,33,40,80,130 | 10000 | 8000 |

Ultrasonic Transducer,Ultrasonic Generator,Ultrasonic Cleaner -SKSONIC

Ultrasonic Transducer,Ultrasonic Generator,Ultrasonic Cleaner -SKSONIC