However, in real production, most circuit boards are equipped with electronic components such as capacitors, transformers, and crystal oscillators. In view of this, ultrasonic cleaning of circuit boards is convenient and fast, but new problems arise. For example, some parts cannot be directly cleaned in an ultrasonic cleaning tank because the plastic on the surface of the capacitor will be corroded by organic solvents, the markings on the capacitor will be washed off by ultrasonic waves, and the transformer cannot easily dry when water enters.

However, in real production, most circuit boards are equipped with electronic components such as capacitors, transformers, and crystal oscillators. In view of this, ultrasonic cleaning of circuit boards is convenient and fast, but new problems arise. For example, some parts cannot be directly cleaned in an ultrasonic cleaning tank because the plastic on the surface of the capacitor will be corroded by organic solvents, the markings on the capacitor will be washed off by ultrasonic waves, and the transformer cannot easily dry when water enters.

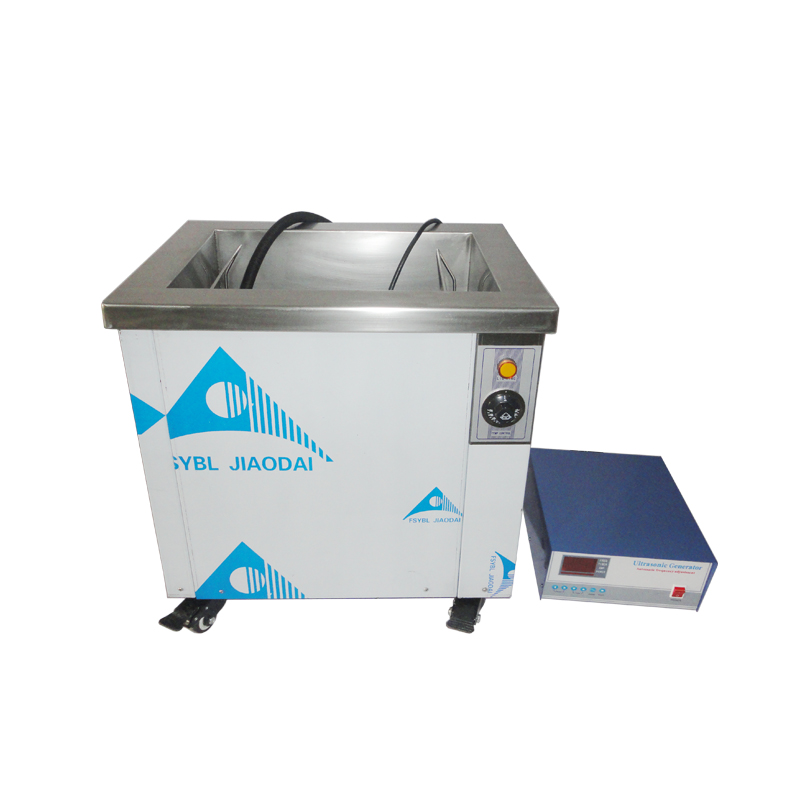

With years of experience in ultrasonic cleaning machines, using a flat cleaning method and only cleaning the welding surface of the circuit board can also bring good cleaning results. The biggest difference between the flat cleaning method of circuit boards and conventional ultrasonic cleaning of circuit boards is that the former only needs to put the cleaned area into the cleaning solvent (the cleaning depth is adjustable), while the latter places the entire circuit board into the ultrasonic cleaning tank.

| Type | Internal size L*W*H (mm) |

Frequency (Khz) | Power(W) | Heating(W) |

| PU-1006TT | 280×210×210 | 20,28,33,40,80,130 | 300 | 1000 |

| PU-1012TT | 400×310×280 | 20,28,33,40,80,130 | 600 | 3000 |

| PU-1018TT | 490×360×320 | 20,28,33,40,80,130 | 900 | 3000 |

| PU-1024TT | 630×430×320 | 20,28,33,40,80,130 | 1200 | 4000 |

| PU-1030TT | 630×530×320 | 20,28,33,40,80,130 | 1500 | 4000 |

| PU-1036TT | 680×530×360 | 20,28,33,40,80,130 | 1800 | 5000 |

| PU-1040TT | 680×570×400 | 20,28,33,40,80,130 | 2000 | 5000 |

| PU-1041TT | 730×570×450 | 20,28,33,40,80,130 | 2400 | 6000 |

| PU-1042TT | 790×670×510 | 20,28,33,40,80,130 | 3000 | 6000 |

| PU-1043TT | 850×770×570 | 20,28,33,40,80,130 | 4000 | 7000 |

| PU-1044ST | 910×820×620 | 20,28,33,40,80,130 | 5000 | 7000 |

| PU-1045TT | 960×870×680 | 20,28,33,40,80,130 | 8000 | 8000 |

| PU-1046TT | 1100×930×730 | 20,28,33,40,80,130 | 10000 | 8000 |

Ultrasonic Transducer,Ultrasonic Generator,Ultrasonic Cleaner -SKSONIC

Ultrasonic Transducer,Ultrasonic Generator,Ultrasonic Cleaner -SKSONIC