There are also some issues that need to be noted in the application process of industrial ultrasonic emulsification and dispersion extraction equipment. For example, for different raw materials and target components, it is necessary to choose appropriate solvents and extraction conditions to ensure the optimal extraction effect. In addition, the operation and maintenance of equipment also require professional skills and knowledge to ensure the normal operation and service life of the equipment. Therefore, when applying this device, it is necessary to fully understand its working principle and application scope, and make choices and adjustments based on actual situations.

There are also some issues that need to be noted in the application process of industrial ultrasonic emulsification and dispersion extraction equipment. For example, for different raw materials and target components, it is necessary to choose appropriate solvents and extraction conditions to ensure the optimal extraction effect. In addition, the operation and maintenance of equipment also require professional skills and knowledge to ensure the normal operation and service life of the equipment. Therefore, when applying this device, it is necessary to fully understand its working principle and application scope, and make choices and adjustments based on actual situations.

Industrial ultrasonic emulsification dispersion extraction equipment, as an advanced extraction technology equipment, provides strong technical support for modern industrial production. It not only improves production efficiency and quality, but also provides guarantees for the stability and safety of products. In the future development, with the continuous progress of technology and the expansion of application areas, it is believed that this device will be applied and promoted in more fields, bringing more convenience and benefits to people’s production and life.

|

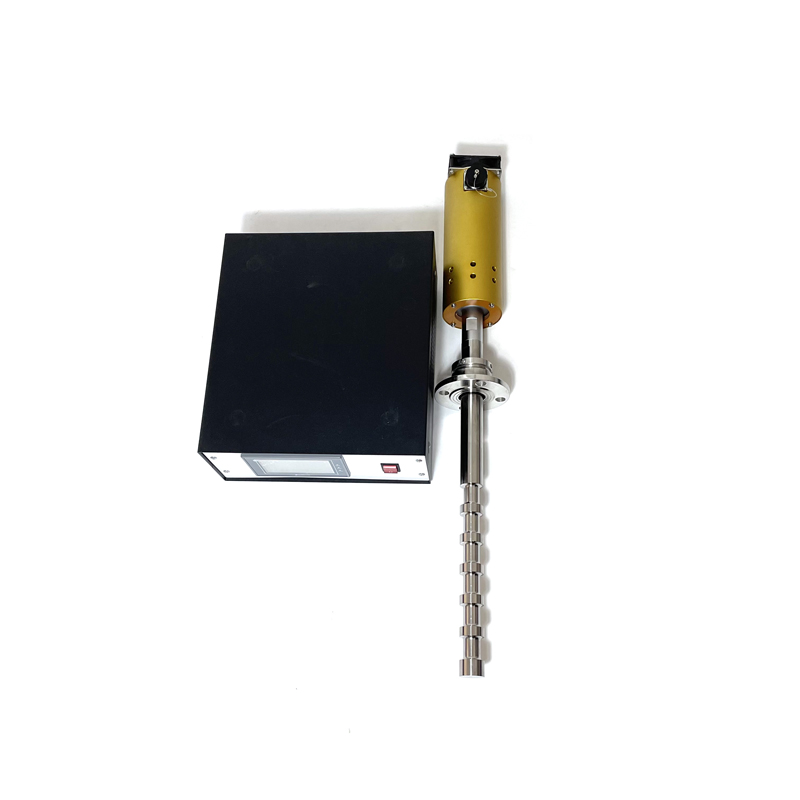

Tubular Equipment

Type

|

Tubular Transducer

Type

|

Frequency

(KHz)

|

Ultrasound

Output(W)

|

Total Length

(mm)

|

Diameter

(mm)

|

Static Capacity

(pF±10%)

|

|

PU-UE1

|

US-61

|

15-28

|

1000

|

500

|

Φ50-55

|

68000

|

|

PU-UE5

|

US-25

|

15-28

|

1500

|

850

|

Φ50-55

|

68000

|

|

PU-UE6

|

US-16

|

15-28

|

2000

|

1100

|

Φ50-55

|

132000

|

Ultrasonic Transducer,Ultrasonic Generator,Ultrasonic Cleaner -SKSONIC

Ultrasonic Transducer,Ultrasonic Generator,Ultrasonic Cleaner -SKSONIC