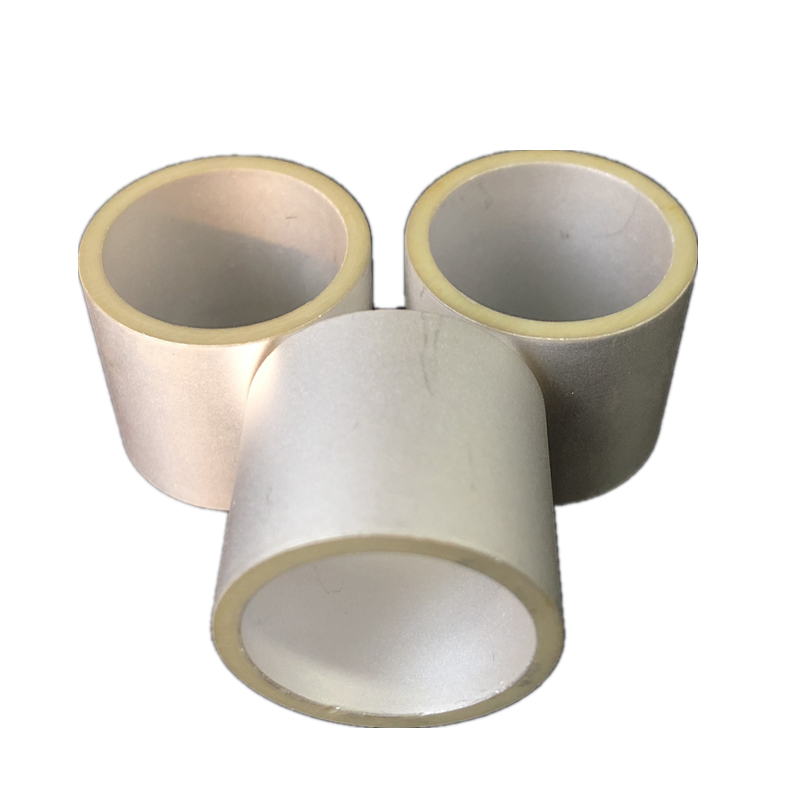

The manufacturing process of piezoelectric ceramic sheets mainly includes processes such as batching, forming, sintering, slicing, polarization, and application. Among them, ingredients are the foundation for manufacturing piezoelectric ceramic sheets, and high-purity raw materials need to be selected, such as barium titanate, barium zirconate, etc; Forming is the process of making ingredients into a certain shape of the body; Sintering is the process of volatilizing organic matter from the green body while adjusting the crystal structure; Slicing is the process of cutting the sintered body into thin slices of a certain thickness; Polarization is achieved by applying an electric field to a thin film to give it piezoelectric properties; The application is to polarize the piezoelectric ceramic. Ceramic tiles are applied in various fields.

The manufacturing process of piezoelectric ceramic sheets mainly includes processes such as batching, forming, sintering, slicing, polarization, and application. Among them, ingredients are the foundation for manufacturing piezoelectric ceramic sheets, and high-purity raw materials need to be selected, such as barium titanate, barium zirconate, etc; Forming is the process of making ingredients into a certain shape of the body; Sintering is the process of volatilizing organic matter from the green body while adjusting the crystal structure; Slicing is the process of cutting the sintered body into thin slices of a certain thickness; Polarization is achieved by applying an electric field to a thin film to give it piezoelectric properties; The application is to polarize the piezoelectric ceramic. Ceramic tiles are applied in various fields.

| Type | Fr(KHz) | (k31)% | C(PF) | d3310-12(CN) | Tg(%) |

| PLS-P51-151110 | 70±5% | 30 | 4680±10% | 500 | 2 |

| PLS-P51-201615 | 50±5% | 30 | 9700±10% | 500 | 2 |

| PLS-P51-252115 | 39±5% | 35 | 12400±10% | 500 | 2 |

| PLS-P51-292520 | 34±5% | 35 | 19400±10% | 550 | 2 |

| PLS-P51-302518 | 33±5% | 35 | 14250±10% | 550 | 2 |

| PLS-P51-322820 | 36±5% | 35 | 21600±10% | 550 | 2 |

| PLS-P51-343020 | 28±5% | 35 | 23000±10% | 550 | 2 |

| PLS-P51-383225 | 26±5% | 35 | 21000±10% | 550 | 2 |

| PLS-P51-403237 | 25±5% | 35 | 24000±10% | 550 | 2 |

| PLS-P51-453925 | 22±5% | 35 | 25200±10% | 550 | 2 |

| PLS-P51-504425 | 19±5% | 35 | 28200±10% | 550 | 2 |

| PLS-P51-553930 | 19±5% | 35 | 33800±10% | 550 | 2 |

| PLS-P51-605430 | 16±5% | 35 | 41000±10% | 550 | 2 |

| PLS-P51-655930 | 15±5% | 35 | 44600±10% | 550 | 2 |

| PLS-P51-756716 | 13±5% | 35 | 20400±10% | 550 | 2 |

| PLS-P51-807420 | 12±5% | 35 | 36900±10% | 550 | 2 |

| PLS-P51-908420 | 10±5% | 35 | 52180±10% | 550 | 2 |

Ultrasonic Transducer,Ultrasonic Generator,Ultrasonic Cleaner -SKSONIC

Ultrasonic Transducer,Ultrasonic Generator,Ultrasonic Cleaner -SKSONIC