Advantages of Ultrasonic Cleaning Machine for Anilox Rolls

Advantages of Ultrasonic Cleaning Machine for Anilox Rolls

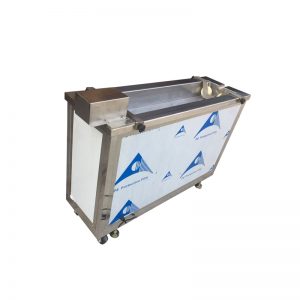

1. Efficient cleaning: The anilox roller ultrasonic cleaning machine utilizes the vibration of ultrasound and the impact force of cleaning solution to quickly and effectively remove dirt and impurities on the surface of the anilox roller, improving cleaning efficiency.

2. No damage to the anilox roller: Due to the high frequency and low energy of ultrasonic vibration, it will not cause damage to the surface of the anilox roller, effectively extending its service life.

3. High degree of automation: The anilox roller ultrasonic cleaning machine is equipped with an automatic control system, which can achieve automated operation, reduce labor intensity, and improve production efficiency.

4. Save time and manpower: Using an anilox roller ultrasonic cleaning machine for cleaning not only shortens the cleaning time, but also greatly reduces the workload of manual cleaning.

5. Wide applicability: The ultrasonic cleaning machine for anilox rollers is not only suitable for cleaning various types of anilox rollers, but also for other types of roller anilox tube patterns

|

Model |

Internal size |

Outsize mm |

Frequency (Khz) |

Power(W) |

Heating(W) |

Total power(W) |

voltage |

|

PLS-DQXJ-1006 |

280×210×210 |

320×250×350 |

20,28,33,40,80,130 |

300 |

1000 |

1300 |

220V |

|

PLS-DQXJ-1012 |

400×310×280 |

520×430×600 |

20,28,33,40,80,130 |

600 |

3000 |

3600 |

220V |

|

PLS-DQXJ-1018 |

490×360×320 |

610×480×675 |

20,28,33,40,80,130 |

900 |

3000 |

3900 |

220V |

|

PLS-DQXJ-1024 |

630×430×320 |

740×550×675 |

20,28,33,40,80,130 |

1200 |

4000 |

5200 |

220V |

|

PLS-DQXJ-1030 |

630×530×320 |

750×650×675 |

20,28,33,40,80,130 |

1500 |

4000 |

5500 |

220V |

|

PLS-DQXJ-1036 |

680×530×360 |

800×650×700 |

20,28,33,40,80,130 |

1800 |

5000 |

6800 |

220V |

|

PLS-DQXJ-1040 |

680×570×400 |

830×710×735 |

20,28,33,40,80,130 |

2000 |

5000 |

7000 |

220V |

|

Welcome OEM size enquire |

|||||||

Ultrasonic Transducer,Ultrasonic Generator,Ultrasonic Cleaner -SKSONIC

Ultrasonic Transducer,Ultrasonic Generator,Ultrasonic Cleaner -SKSONIC