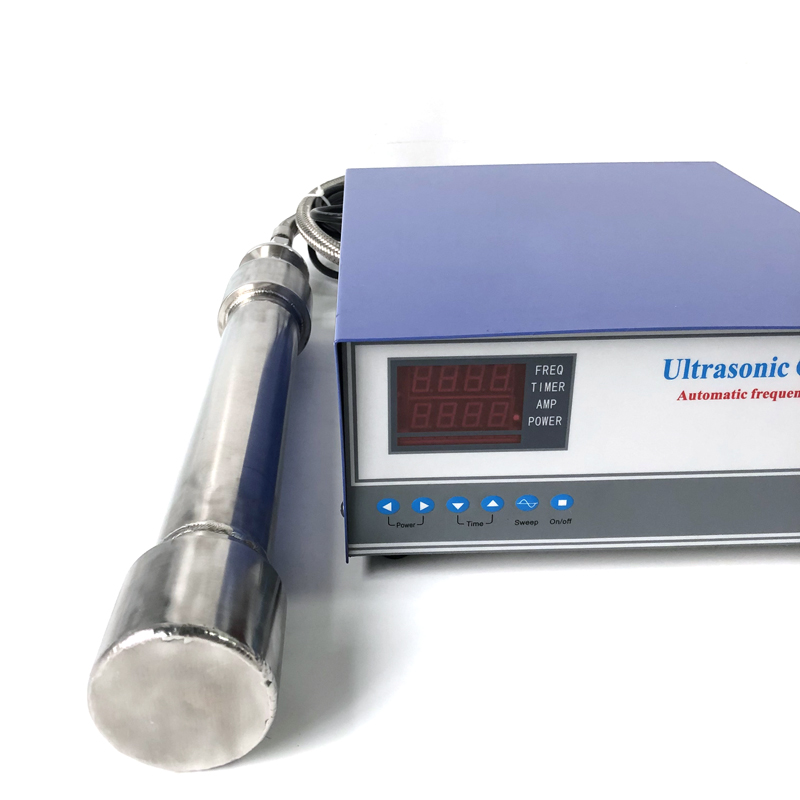

Stainless steel ultrasonic vibration rod uses the principle of ultrasonic dispersion to break solid particles or biological tissues in the liquid under the action of ultrasonic. This process is called ultrasonic crushing, mainly achieved by combining the ultrasonic cavitation effect and mechanical action of ultrasonic propagation in the medium. The main manifestation is that when ultrasonic propagates in the liquid medium, it creates dense areas, and negative pressure can create many cavities in the medium, These cavities expand and explode with the high-frequency pressure changes of vibration. When the vacuum cavity explodes, it generates an instantaneous pressure of thousands or even tens of thousands of atmospheres, such as high temperatures of up to 5000K, pressures greater than 200MPA, and cooling rates of up to 010K/P. Such a large impact force can shatter surrounding material particles during local explosions in the vacuum cavity. On the other hand, due to the intense vibration generated by ultrasonic propagation in liquids, substances undergo high motion, collide with each other or collide with the vessel walls to break them, thus achieving the principles of ultrasonic crushing, ultrasonic dispersion, and ultrasonic wall breaking.

Stainless steel ultrasonic vibration rod uses the principle of ultrasonic dispersion to break solid particles or biological tissues in the liquid under the action of ultrasonic. This process is called ultrasonic crushing, mainly achieved by combining the ultrasonic cavitation effect and mechanical action of ultrasonic propagation in the medium. The main manifestation is that when ultrasonic propagates in the liquid medium, it creates dense areas, and negative pressure can create many cavities in the medium, These cavities expand and explode with the high-frequency pressure changes of vibration. When the vacuum cavity explodes, it generates an instantaneous pressure of thousands or even tens of thousands of atmospheres, such as high temperatures of up to 5000K, pressures greater than 200MPA, and cooling rates of up to 010K/P. Such a large impact force can shatter surrounding material particles during local explosions in the vacuum cavity. On the other hand, due to the intense vibration generated by ultrasonic propagation in liquids, substances undergo high motion, collide with each other or collide with the vessel walls to break them, thus achieving the principles of ultrasonic crushing, ultrasonic dispersion, and ultrasonic wall breaking.

|

Tubular Equipment

Type

|

Tubular Transducer

Type

|

Frequency

(KHz)

|

Ultrasound

Output(W)

|

Total Length

(mm)

|

Diameter

(mm)

|

Static Capacity

(pF±10%)

|

|

PU-UE1

|

US-61

|

15-28

|

1000

|

500

|

Φ50-55

|

68000

|

|

PU-UE5

|

US-25

|

15-28

|

1500

|

850

|

Φ50-55

|

68000

|

|

PU-UE6

|

US-16

|

15-28

|

2000

|

1100

|

Φ50-55

|

132000

|

Ultrasonic Transducer,Ultrasonic Generator,Ultrasonic Cleaner -SKSONIC

Ultrasonic Transducer,Ultrasonic Generator,Ultrasonic Cleaner -SKSONIC