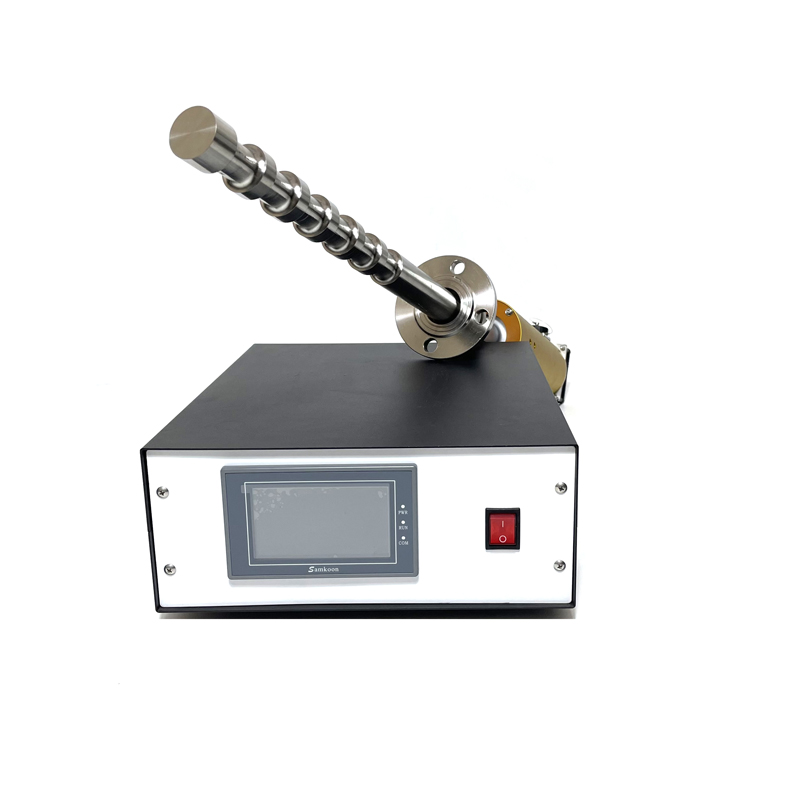

Ultrasonic mixing and stirring vibrating rods have been widely used in industrial fields such as food processing, papermaking, coatings, chemicals, pharmaceuticals, textiles, petroleum, metallurgy, etc. Ultrasonic equipment can be easily installed on existing production lines, making it easier for manufacturers to upgrade their equipment at a lower cost.

The structure design of high-power concentrated ultrasonic vibration rod is scientific and reasonable. By introducing room temperature air with a lower temperature than the inner cavity into the sealed ultrasonic vibration rod cavity, the heat generated by ultrasonic vibration can be adsorbed and carried out of the ultrasonic vibration rod cavity by the relatively low temperature room temperature air during the use of the ultrasonic vibration rod, thereby avoiding the piezoelectric ceramic oscillator inside the ultrasonic vibration rod from continuously maintaining a certain high temperature state, Greatly eliminates damage to piezoelectric ceramic oscillators during high-temperature use.

|

Tubular Equipment

Type

|

Tubular Transducer

Type

|

Frequency

(KHz)

|

Ultrasound

Output(W)

|

Total Length

(mm)

|

Diameter

(mm)

|

Static Capacity

(pF±10%)

|

|

PU-UE1

|

US-61

|

15-28

|

1000

|

500

|

Φ50-55

|

68000

|

|

PU-UE5

|

US-25

|

15-28

|

1500

|

850

|

Φ50-55

|

68000

|

|

PU-UE6

|

US-16

|

15-28

|

2000

|

1100

|

Φ50-55

|

132000

|

Ultrasonic Transducer,Ultrasonic Generator,Ultrasonic Cleaner -SKSONIC

Ultrasonic Transducer,Ultrasonic Generator,Ultrasonic Cleaner -SKSONIC