The characteristics of ultrasonic cutting machines are that they do not require sharp blades, do not require significant pressure, and do not cause edge collapse or damage to cutting materials.

The characteristics of ultrasonic cutting machines are that they do not require sharp blades, do not require significant pressure, and do not cause edge collapse or damage to cutting materials.

The cutting blade is subjected to ultrasonic vibration with extremely low frictional resistance, making the material being cut less likely to stick to the blade. Significant cutting effect on frozen, viscous, and elastic materials. Especially effective for cutting food, rubber, or objects that are not easily pressurized.

At the same time as cutting, the cutting area has a fusion effect. Sealing the cutting area can prevent loosening of the material structure (such as textile material flash). The use of ultrasonic cutting machines can also be expanded, such as digging holes, shoveling, scraping paint, carving, slicing, and so on.

| Type | power (W) |

Frequency | Welding time | Contains |

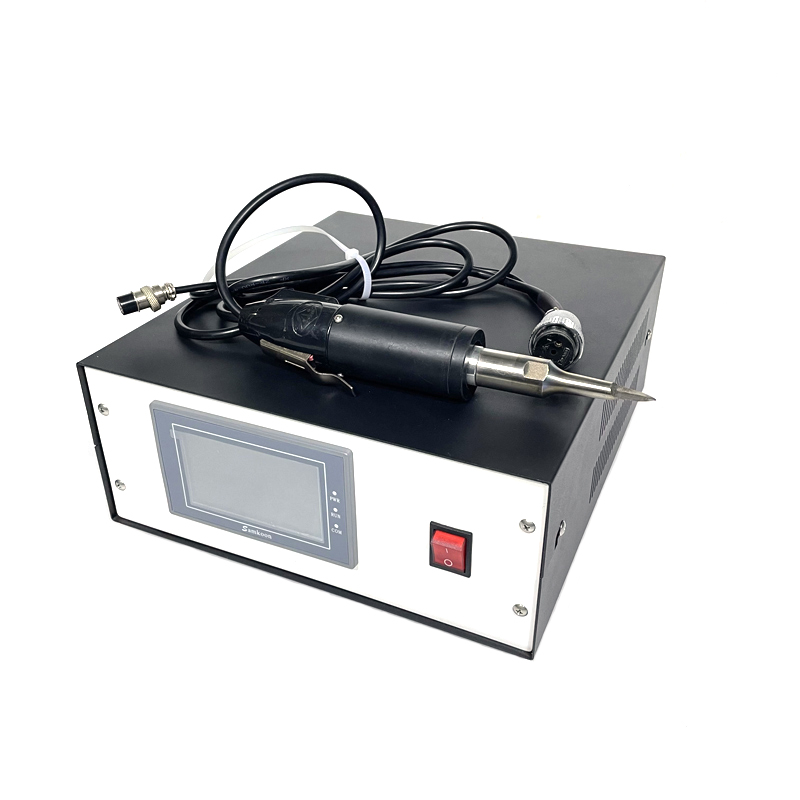

| PU-QG100W | 100W | 30khz,35khz,40khz | 0.1-3sec | generator , transducer ,horn,head |

| PU-QG300W | 300W | 30khz,35khz,40khz | 0.1-3sec | generator , transducer ,horn,head |

| PU-QG500W | 500W | 30khz,35khz,40khz | 0.1-3sec | generator , transducer ,horn,head |

Ultrasonic Transducer,Ultrasonic Generator,Ultrasonic Cleaner -SKSONIC

Ultrasonic Transducer,Ultrasonic Generator,Ultrasonic Cleaner -SKSONIC