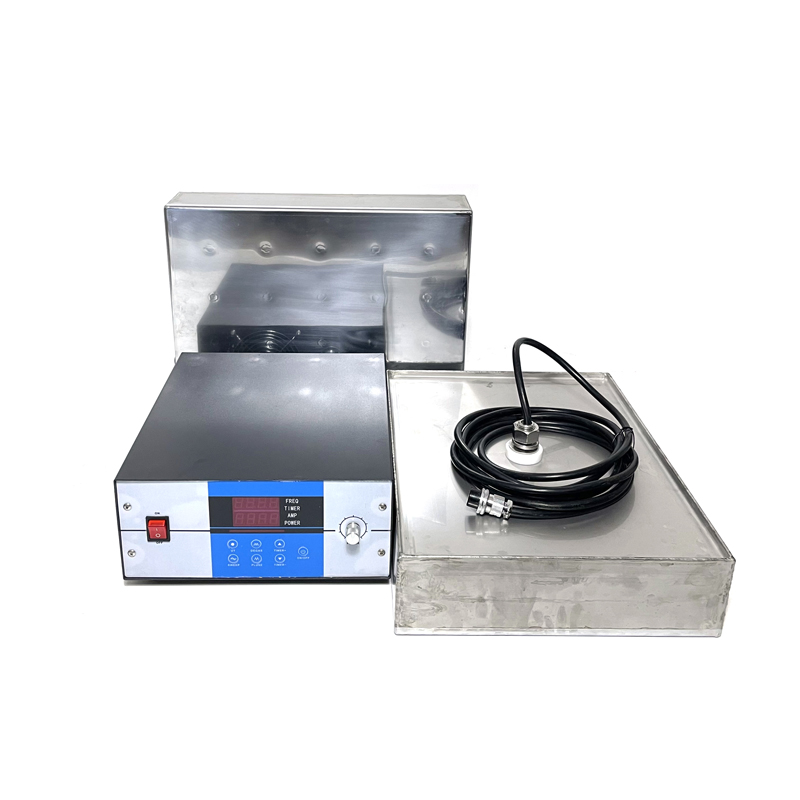

Many cleaning equipment manufacturers believe that the production of ultrasonic vibration boxes is much simpler than ultrasonic generators, as long as the vibrator is bonded inside the vibration box, connected to the wire, and then the vibration box is welded. Little does it know that for precision cleaning, any detail in the production process of the vibration box may affect the cleaning effect, efficiency, consistency, and the service life of the ultrasonic system. Therefore, a correct understanding and strict control of the manufacturing process of the vibration box is a prerequisite for producing a qualified ultrasonic system.

Many cleaning equipment manufacturers believe that the production of ultrasonic vibration boxes is much simpler than ultrasonic generators, as long as the vibrator is bonded inside the vibration box, connected to the wire, and then the vibration box is welded. Little does it know that for precision cleaning, any detail in the production process of the vibration box may affect the cleaning effect, efficiency, consistency, and the service life of the ultrasonic system. Therefore, a correct understanding and strict control of the manufacturing process of the vibration box is a prerequisite for producing a qualified ultrasonic system.

| Type | Diamention(mm) | Frequency (Khz) | Power(W) | Ultrasonic Transducer |

| PU-UITP300W | 300*190*100 | 25,28,33,40,80,130 | 300 | 6 |

| PU-UITP600W | 360*275*100 | 25,28,33,40,80,130 | 600 | 12 |

| PU-UITP1000W | 450*350*100 | 25,28,33,40,80,130 | 1000 | 20 |

| PU-UITP1200W | 470*380*100 | 25,28,33,40,80,130 | 1200 | 24 |

| PU-UITP1500W | 520*450*100 | 25,28,33,40,80,130 | 1500 | 30 |

| PU-UITP1800W | 560*450*100 | 25,28,33,40,80,130 | 1800 | 36 |

| PU-UITP2000W | 650*450*100 | 25,28,33,40,80,130 | 2000 | 40 |

| PU-UITP2400W | 740*520*100 | 25,28,33,40,80,130 | 2400 | 48 |

| PU-UITP3000W | 820*540*100 | 25,28,33,40,80,130 | 3000 | 60 |

| PU-UITP5000W | 1200*590*100 | 25,28,33,40,80,130 | 5000 | 100 |

| OEM Ultrasonic Immersible Transducer Pack(Size, Frequency,Power) | ||||

Ultrasonic Transducer,Ultrasonic Generator,Ultrasonic Cleaner -SKSONIC

Ultrasonic Transducer,Ultrasonic Generator,Ultrasonic Cleaner -SKSONIC