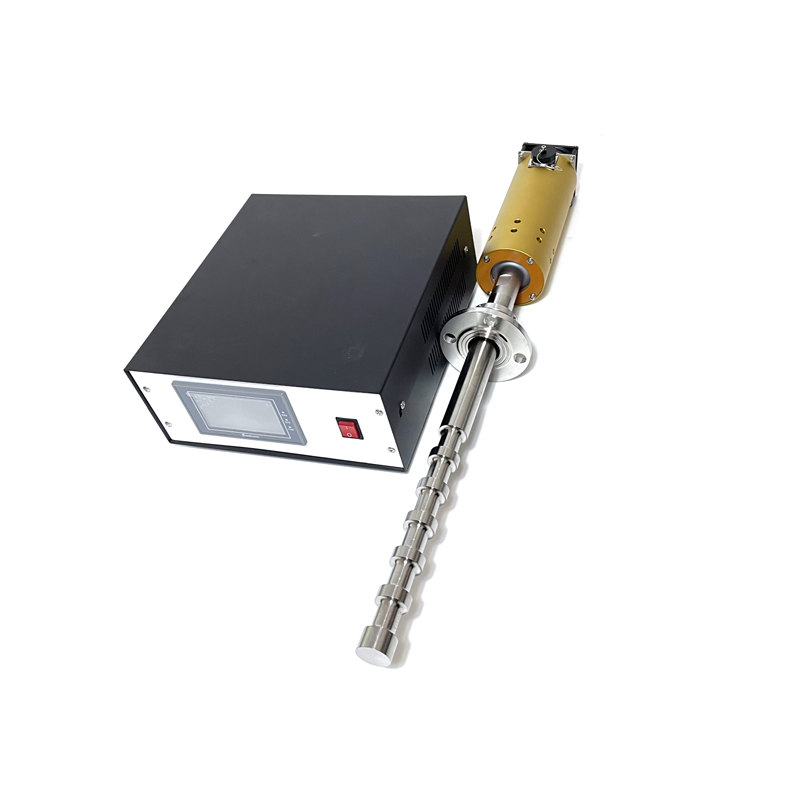

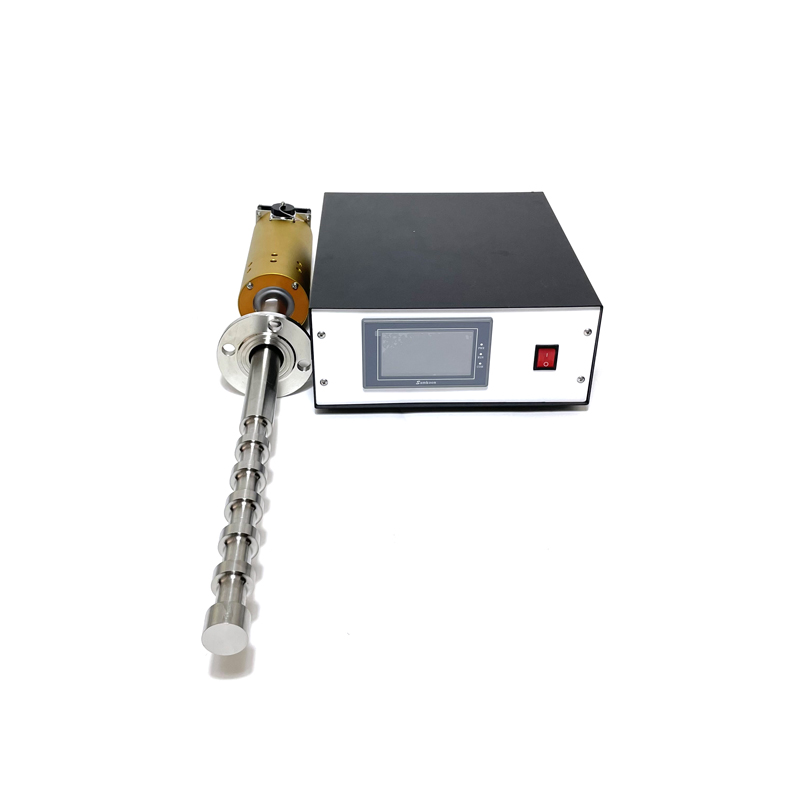

The laboratory ultrasonic vibration rod has a simple structure, a variable amplitude rod design, and a large amplitude, which can cause water waves in the reaction kettle. The fingers are immersed in the liquid, and the needle feeling is strong, all of which are manifestations of the high-power and large amplitude of the oscillator. The laboratory ultrasonic vibration rod is made of acid and alkali resistant titanium alloy material, with high vibration transmission efficiency and greatly improved service life.

The cavitation effect of the laboratory ultrasonic vibration rod is generated around the energy gathering rod, and the ultrasonic energy is evenly distributed in the groove, which has a service life of more than 1.5 times that of traditional vibration plates.

The shaped ultrasonic vibrating rod uses cavitation to generate vibration from around the vibrating rod. The ultrasonic energy of the shaped ultrasonic vibrating rod is evenly distributed around the tank reactor, in order to achieve the best emulsification, mixing and dispersion effect. The concentrated energy ultrasonic vibrating rod is applied in emulsification, separation, homogenization, extraction, macromolecules, and other aspects to improve production capacity. The use of concentrated energy ultrasonic vibration rods has played an undeniable role in uniform mixing, as they play a crucial role in homogenization. The catalytic effect of the concentrated energy ultrasonic vibration rod is extremely amazing, with an efficiency increase of multiple times, which needs to be applied in the chemical industry or has broad prospects.

|

Tubular Equipment

Type

|

Tubular Transducer

Type

|

Frequency

(KHz)

|

Ultrasound

Output(W)

|

Total Length

(mm)

|

Diameter

(mm)

|

Static Capacity

(pF±10%)

|

|

PU-UE1

|

US-61

|

15-28

|

1000

|

500

|

Φ50-55

|

68000

|

|

PU-UE5

|

US-25

|

15-28

|

1500

|

850

|

Φ50-55

|

68000

|

|

PU-UE6

|

US-16

|

15-28

|

2000

|

1100

|

Φ50-55

|

132000

|

Ultrasonic Transducer,Ultrasonic Generator,Ultrasonic Cleaner -SKSONIC

Ultrasonic Transducer,Ultrasonic Generator,Ultrasonic Cleaner -SKSONIC