The circuit board ultrasonic power generator used for industrial cleaning machines is currently the most cost-effective equipment in the cleaning industry. Due to its many advantages, it plays an increasingly important role in industrial and agricultural production and daily life, and its market prospects are very broad. At present, there is still a considerable gap between China and advanced ultrasonic technology abroad, and the technical status is far from meeting the current requirements of various fields in China. Therefore, conducting deeper research on ultrasonic technology has important practical significance.

The circuit board ultrasonic power generator used for industrial cleaning machines is currently the most cost-effective equipment in the cleaning industry. Due to its many advantages, it plays an increasingly important role in industrial and agricultural production and daily life, and its market prospects are very broad. At present, there is still a considerable gap between China and advanced ultrasonic technology abroad, and the technical status is far from meeting the current requirements of various fields in China. Therefore, conducting deeper research on ultrasonic technology has important practical significance.

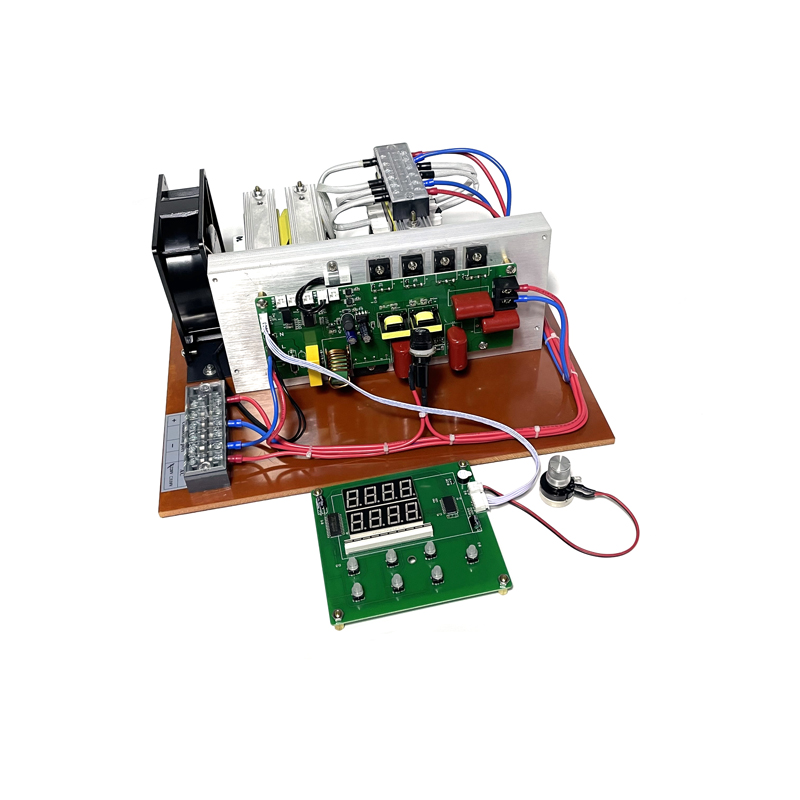

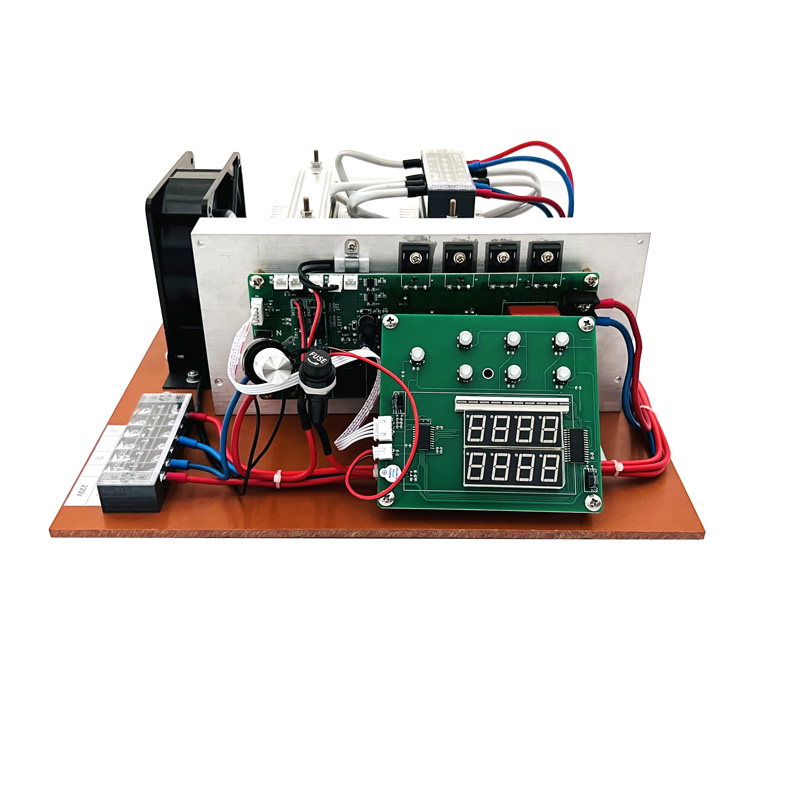

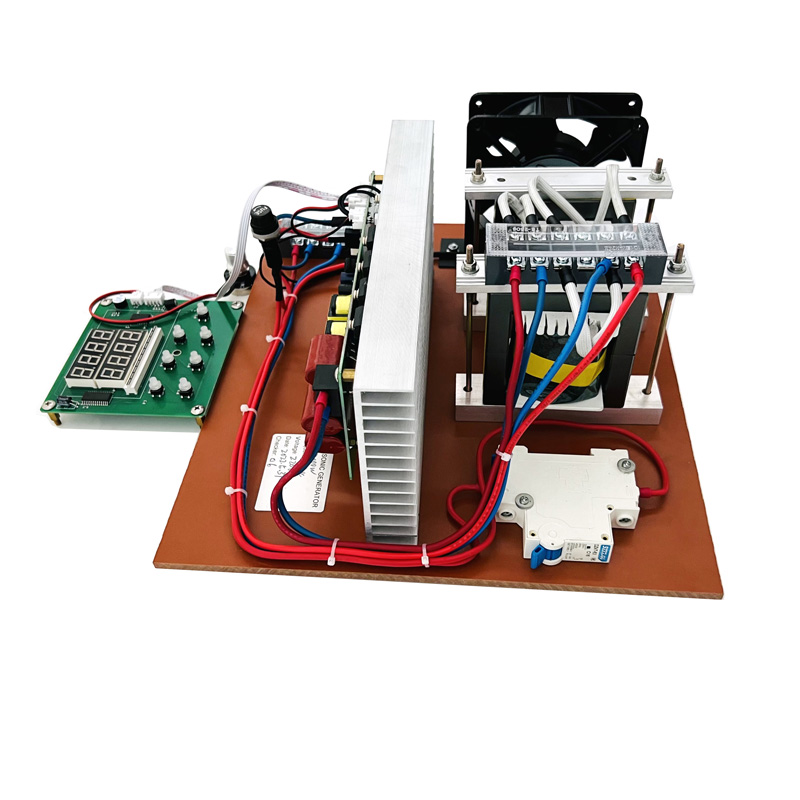

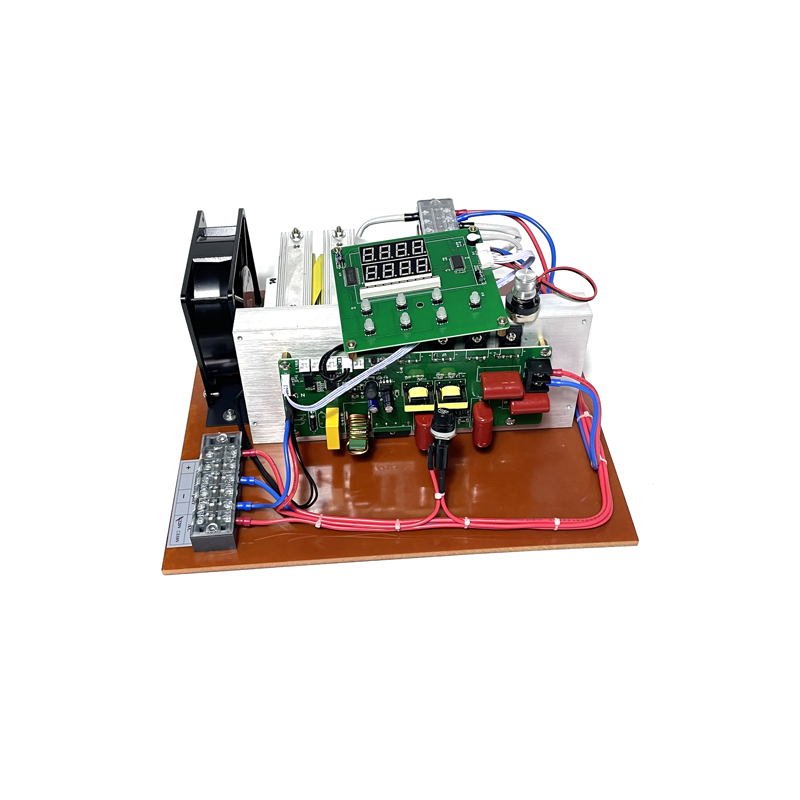

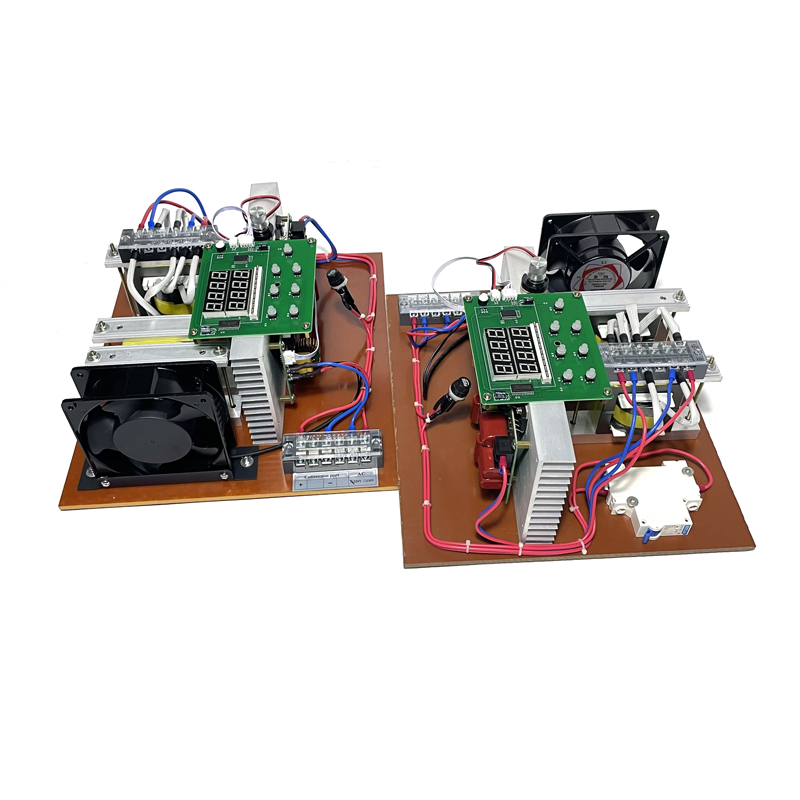

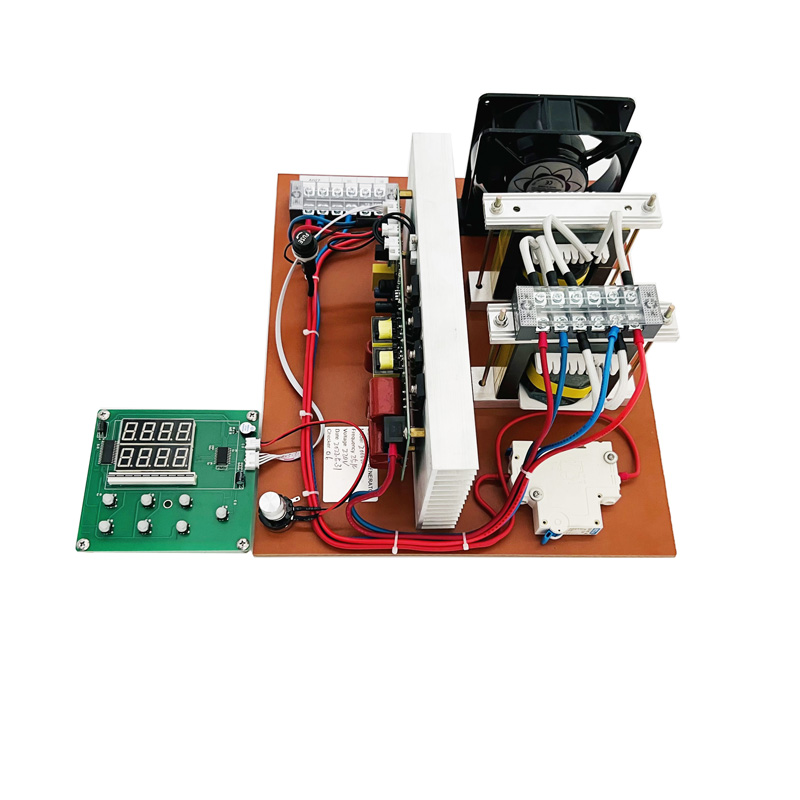

The circuit board ultrasonic power generator used for industrial cleaning machines is an important component of ultrasonic equipment, responsible for providing electrical energy to ultrasonic transducers. The development of circuit board ultrasonic power generators for industrial cleaning machines is a key technology that determines the development of the ultrasonic industry. On the basis of analyzing the power supply of the ultrasonic cleaning machine, the impedance characteristics of the piezoelectric transducer were analyzed and equivalent calculations were made, and a design scheme for the ultrasonic power supply was proposed.

The principle and development process of the hardware circuit of the circuit board ultrasonic power generator used in industrial cleaning machine systems, as well as the design process of the system software. At the same time, the actual production of each component circuit of the ultrasonic power supply was carried out, and the calculation and selection methods of inductance and impedance matching transformers were provided. At the end of the experiment, relevant experimental waveforms and data of the ultrasonic power supply system were provided. The experimental results of a low-power ultrasonic power supply controlled by an AT89C51 microcontroller show that this power supply can carry a certain range of loads, work stably, resonate well, and have high reliability, achieving the expected results.

| Type | Power(W) | Frequency (KHz) |

| PU-DGPCB300W | 300 | 20khz,25khz,28khz,33khz,40khz Frequency is adjustable |

| PU-DGPCB600W | 600 | 20khz,25khz,28khz,33khz,40khz Frequency is adjustable |

| PU-DGPCB900W | 900 | 20khz,25khz,28khz,33khz,40khz Frequency is adjustable |

| PU-DGPCB1000W | 1000 | 20khz,25khz,28khz,33khz,40khz Frequency is adjustable |

| PU-DGPCB1200W | 1200 | 20khz,25khz,28khz,33khz,40khz Frequency is adjustable |

| UCE-HPPCB1500W | 1500 | 20khz,25khz,28khz,33khz,40khz Frequency is adjustable |

| PU-DGPCB1800W | 1800 | 20khz,25khz,28khz,33khz,40khz Frequency is adjustable |

| PU-DGPCB2000W | 2000 | 20khz,25khz,28khz,33khz,40khz Frequency is adjustable |

| PU-DGPCB2400W | 2400 | 20khz,25khz,28khz,33khz,40khz Frequency is adjustable |

| PU-DGPCB3000W | 3000 | 20khz,25khz,28khz,33khz,40khz Frequency is adjustable |

Ultrasonic Transducer,Ultrasonic Generator,Ultrasonic Cleaner -SKSONIC

Ultrasonic Transducer,Ultrasonic Generator,Ultrasonic Cleaner -SKSONIC