Ultrasonic cutting

Ultrasonic cutting

1. High stability. During the operation of the ultrasonic generator, electromagnetic vibration is generated and converted into mechanical vibration, which is transmitted to the cutting blade and the cutting material. Mechanical cutting is carried out, so there is no need for sharp edges. The blade wear is minimal, and the blade can be replaced on its own.

2. Safety and environmental protection. Ultrasonic knife cutting, with a blade temperature below 20 ℃, does not produce smoke and odor, eliminating the risk of injury and fire during cutting.

3. Cut neatly. Due to the high-frequency vibration of ultrasonic cutting, the material will not adhere to the surface of the blade, and only a small amount of pressure is required during cutting. It will not deform and wear fragile and soft materials, and the fabric cutting will automatically seal the edge, without causing edge collapse.

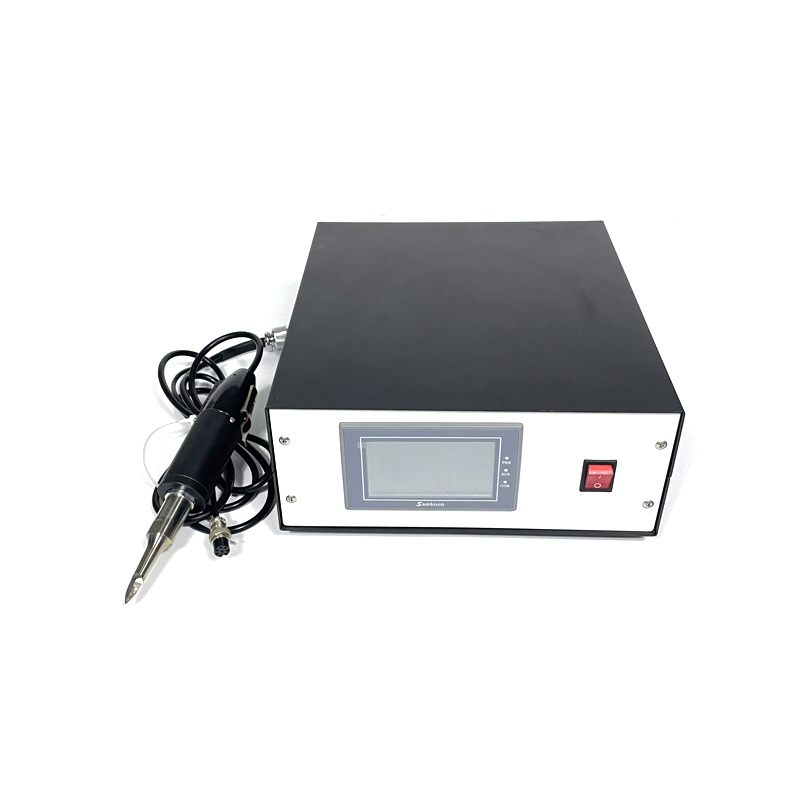

4. Easy to operate. The cutting knife is connected to an ultrasonic generator, which is connected to a 220V mains power supply. Opening the switch allows for cutting, supporting handheld and machine mounted cutting.

5. Scope of application. Rubber, vulcanized latex, non vulcanized latex, food and various textile materials, and plastic sheets can all be cut by ultrasound.

| Type | power (W) |

Frequency | Welding time | Contains |

| PU-QG100W | 100W | 30khz,35khz,40khz | 0.1-3sec | generator , transducer ,horn,head |

| PU-QG300W | 300W | 30khz,35khz,40khz | 0.1-3sec | generator , transducer ,horn,head |

| PU-QG500W | 500W | 30khz,35khz,40khz | 0.1-3sec | generator , transducer ,horn,head |

Ultrasonic Transducer,الٹراسونک جنریٹر,الٹراسونک کلینر - ایس کے ایس او سی

Ultrasonic Transducer,الٹراسونک جنریٹر,الٹراسونک کلینر - ایس کے ایس او سی