Advantages of circulating filtration ultrasonic cleaning machine:

Advantages of circulating filtration ultrasonic cleaning machine:

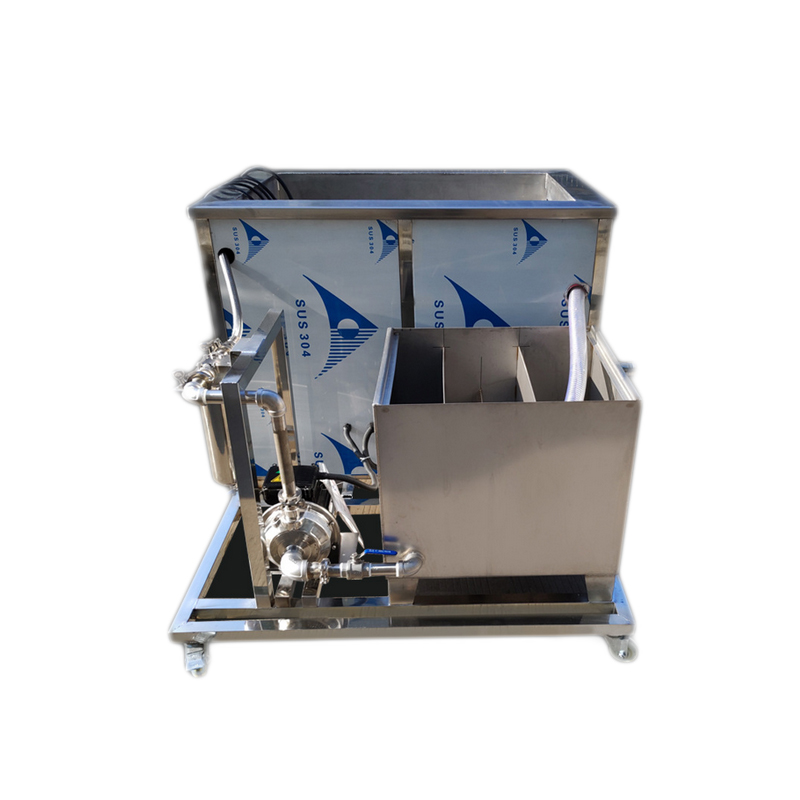

1. Efficient cleaning: The circulating filtration ultrasonic cleaning machine utilizes the vibration of ultrasound and the circulating filtration system to achieve efficient cleaning of the surface of objects, especially for difficult to clean dead corners and complex structures, which have significant advantages.

2. Environmental protection and energy conservation: Compared to traditional cleaning methods, the circulating filtration ultrasonic cleaning machine has the advantages of water conservation and energy conservation. Meanwhile, due to its efficient cleaning effect, it can significantly reduce cleaning time and labor costs.

3. Multi use: The circulating filtering ultrasonic cleaning machine is not only suitable for cleaning hard materials such as metals and ceramics, but also for cleaning soft materials such as plastics and glass, with a wide range of applications.

4. Easy to operate: The operation of the circulating filtration ultrasonic cleaning machine is simple and convenient, and ordinary employees can get started with it after simple training. Meanwhile, the device adopts an intelligent control system, which can achieve automated operation and greatly reduce labor costs.

5. Stable cleaning effect: The circulating filtration system of the ultrasonic cleaning machine can continuously update the cleaning medium, ensuring stable and long-lasting cleaning effect. At the same time, the equipment is also equipped with a filtering device, which can effectively remove impurities in the cleaning medium, further ensuring the reliability of the cleaning effect.

The circulating filtration ultrasonic cleaning machine, as an efficient and environmentally friendly cleaning equipment, has been widely used in various fields. Its unique advantages and wide application range make it an ideal choice for the cleaning industry. With the continuous progress of technology and the increasing demand for applications, the circulating filtration ultrasonic cleaning machine will play a more important role in the future.

|

Model |

Internal size |

Outsize mm |

Frequency (Khz) |

Power(W) |

Heating(W) |

Total power(W) |

voltage |

|

PLS-DQXJ-1006 |

280×210×210 |

320×250×350 |

20,28,33,40,80,130 |

300 |

1000 |

1300 |

220V |

|

PLS-DQXJ-1012 |

400×310×280 |

520×430×600 |

20,28,33,40,80,130 |

600 |

3000 |

3600 |

220V |

|

PLS-DQXJ-1018 |

490×360×320 |

610×480×675 |

20,28,33,40,80,130 |

900 |

3000 |

3900 |

220V |

|

PLS-DQXJ-1024 |

630×430×320 |

740×550×675 |

20,28,33,40,80,130 |

1200 |

4000 |

5200 |

220V |

|

PLS-DQXJ-1030 |

630×530×320 |

750×650×675 |

20,28,33,40,80,130 |

1500 |

4000 |

5500 |

220V |

|

PLS-DQXJ-1036 |

680×530×360 |

800×650×700 |

20,28,33,40,80,130 |

1800 |

5000 |

6800 |

220V |

|

PLS-DQXJ-1040 |

680×570×400 |

830×710×735 |

20,28,33,40,80,130 |

2000 |

5000 |

7000 |

220V |

|

Welcome OEM size enquire |

|||||||