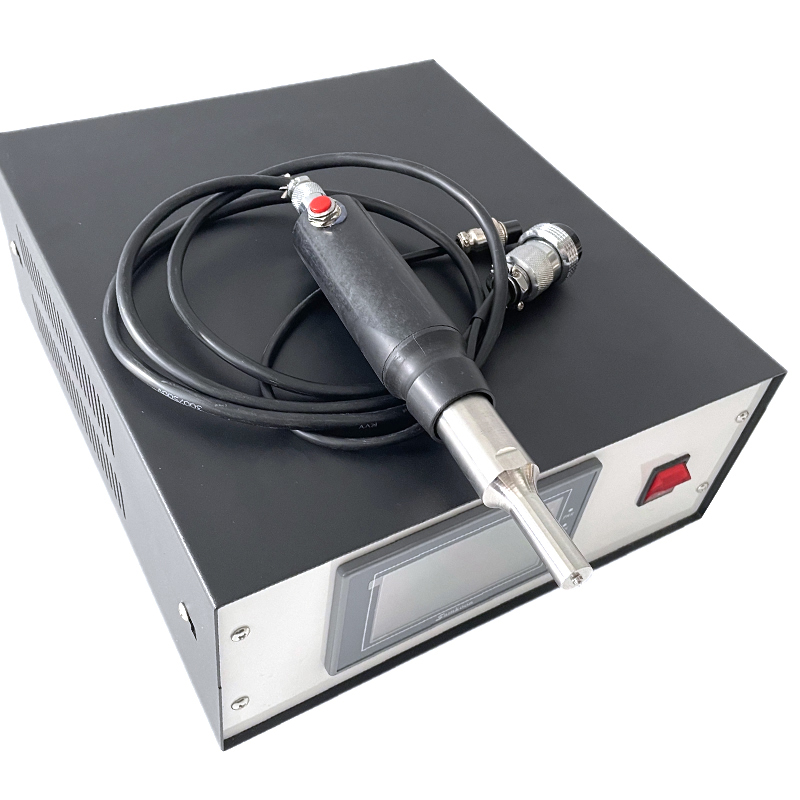

The handheld ultrasonic welding machine can also be used for the welding, riveting, spot welding of thermoplastic products, as well as the inlaying and edge pressing processes between metal and plastic parts. It overcomes the outdated process of using chemical organic melting point agents for bonding, and has the characteristics of low energy consumption, high efficiency, no deformation, no pollution, firm welding, and easy operation. The handle can also be made into a pistol style. By applying pressure to the plastic parts through the handheld part and pressing the ultrasonic switch, ultrasonic waves can be emitted for welding. Research shows that the use of handheld ultrasonic welding machines for welding in the plastic industry is becoming increasingly common around the world. Due to the application of this technology, it can replace the fluxes, adhesives, fasteners, or other mechanical fixation methods required in previous production, thereby improving production efficiency and reducing costs.

The handheld ultrasonic welding machine can also be used for the welding, riveting, spot welding of thermoplastic products, as well as the inlaying and edge pressing processes between metal and plastic parts. It overcomes the outdated process of using chemical organic melting point agents for bonding, and has the characteristics of low energy consumption, high efficiency, no deformation, no pollution, firm welding, and easy operation. The handle can also be made into a pistol style. By applying pressure to the plastic parts through the handheld part and pressing the ultrasonic switch, ultrasonic waves can be emitted for welding. Research shows that the use of handheld ultrasonic welding machines for welding in the plastic industry is becoming increasingly common around the world. Due to the application of this technology, it can replace the fluxes, adhesives, fasteners, or other mechanical fixation methods required in previous production, thereby improving production efficiency and reducing costs.

Plastic hardware, riveting, spot welding, folder positioning, ฯลฯ.

Small size, convenient to work, and does not take up space. Original Japanese transducer with automatic frequency tracking.

Underwear equipment, underwear machinery, ultrasound, ultrasound, hand welding machine;

| ประเภท | พลัง(W) | ความถี่ (กิโลเฮิร์ตซ์) |

| PLS-DHJ-300 | 300W | 15KHz/20khz/28khz/40khz |

| PLS-DHJ-500 | 500W | 15KHz/20khz/28khz/40khz |

| PLS-DHJ-800 | 800W | 15KHz/20khz/28khz/40khz |

| PLS-DHJ-900 | 900W | 15KHz/20khz |

| PLS-DHJ-1000 | 1000W |

15KHz/20khz |

อัลตราโซนิกทรานสดิวเซอร์,เครื่องกําเนิดอัลตราโซนิก,เครื่องทําความสะอาดอัลตราโซนิก -SKSONIC

อัลตราโซนิกทรานสดิวเซอร์,เครื่องกําเนิดอัลตราโซนิก,เครื่องทําความสะอาดอัลตราโซนิก -SKSONIC