Pre dispersion of carbon fibers using ultrasound, followed by the addition of dispersants to continue ultrasonic dispersion, can improve the dispersibility of carbon fibers. The degree of dispersion of glass fiber slurry after cutting cotton is significantly higher than that of uncut cotton. The longer the glass fiber, the harder it is to disperse, and the appropriate fiber dispersion length is 10-12mm. The sedimentation experiment shows that the slurry with Sodium hexametaphosphate has the best dispersion, the lowest sedimentation height and the slowest sedimentation rate.

The main functions of ultrasonic carbon fiber crushing, dispersion and extraction are:

1. Automatic resonance point and power control, eliminating the need for frequent manual energy adjustment

2.99 hour process control timer, controlling the total working time from 1 second to 99 hours, pausing the current running task in real time

3. Display cumulative status during working hours

4. Turn on/off pulse timer to ensure high intensity processing of temperature sensitive samples. Both on and off cycles can be selected from 1 second to 99 hours

5. Automatic amplitude compensation ensures that the probe amplitude does not change due to load changes during the ultrasonic process

6. Sample overload/over temperature protection device

7. Automatic frequency tracking and automatic fault alarm

8. Easy to operate, typing directly

Typical applications of ultrasonic carbon fiber crushing and dispersion extraction:

① Extraction of traditional Chinese medicine, fragmentation of cells, and viral tissue. For example, the extraction of cell contents.

② The dispersion and homogenization of material particles. For example, nano material dispersion (silica, carbon nanotubes, Graphene, etc.)

③ Accelerate dissolution and chemical reactions. For example, for chemical synthesis

|

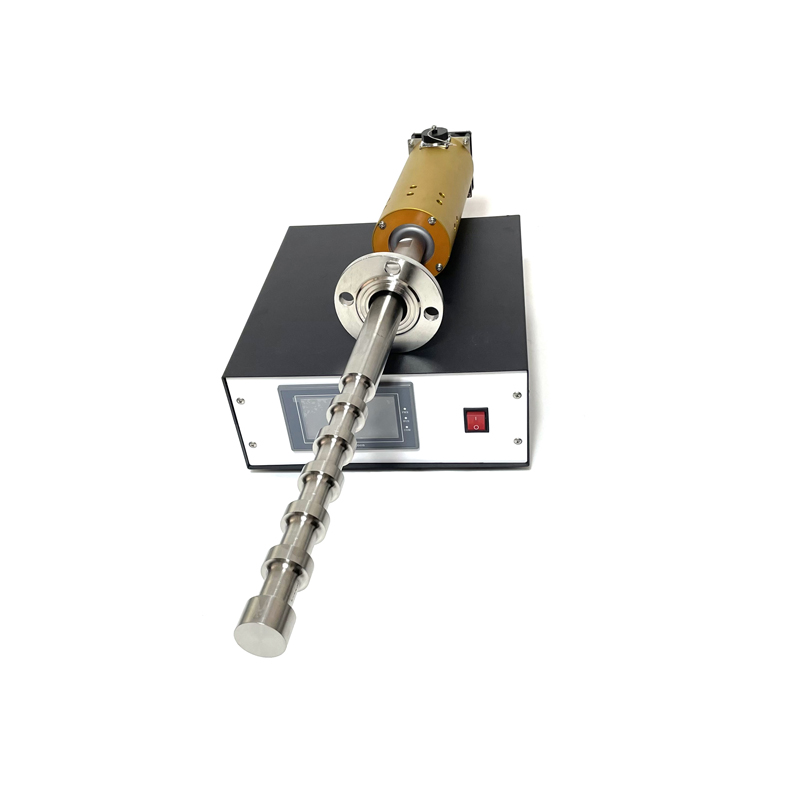

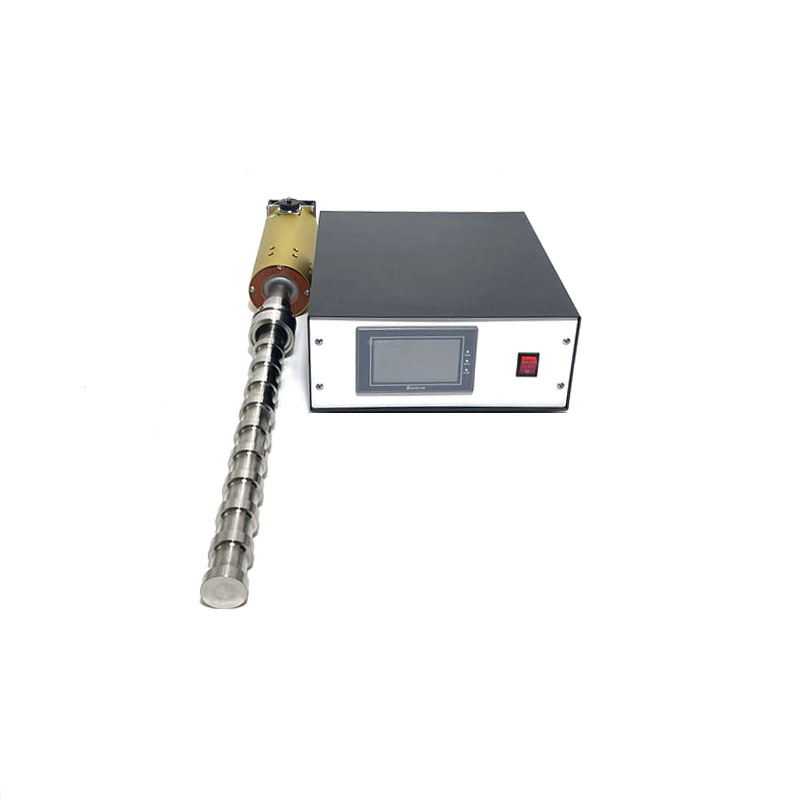

Tubular Equipment

Type

|

Tubular Transducer

Type

|

Frequency

(Khz)

|

Ultrasound

Output(W)

|

Total Length

(mm)

|

Diameter

(mm)

|

Static Capacity

(Pf±10%)

|

|

PU-UE1

|

US-61

|

15-28

|

1000

|

500

|

Φ50-55

|

68000

|

|

PU-UE5

|

US-25

|

15-28

|

1500

|

850

|

Φ50-55

|

68000

|

|

PU-UE6

|

US-16

|

15-28

|

2000

|

1100

|

Φ50-55

|

132000

|

Ultraljud givare,Ultraljud Generator,Ultraljud rengörare -SKSONIC

Ultraljud givare,Ultraljud Generator,Ultraljud rengörare -SKSONIC