Application scope

Application scope

Ultrasonic vibrating rod is applicable to the cleaning of workpieces in various industries, such as the cleaning of precision electronic parts, clock parts, optical glass parts, hardware Machine element, jewelry, semiconductor silicon chips, polyester filter elements/spinnerets, medical devices, and the cleaning of parts before and after electroplating.

The ultrasonic vibration rod is suitable for traditional Chinese medicine extraction, cleaning of the inner wall of thick walled metal pipelines, online ultrasonic scaling prevention of boilers, ultrasonic cleaning in vacuum/pressure situations, various pipeline ultrasonic treatments, and pipeline acoustic chemical treatments.

High energy conversion efficiency, reaching over 80%.

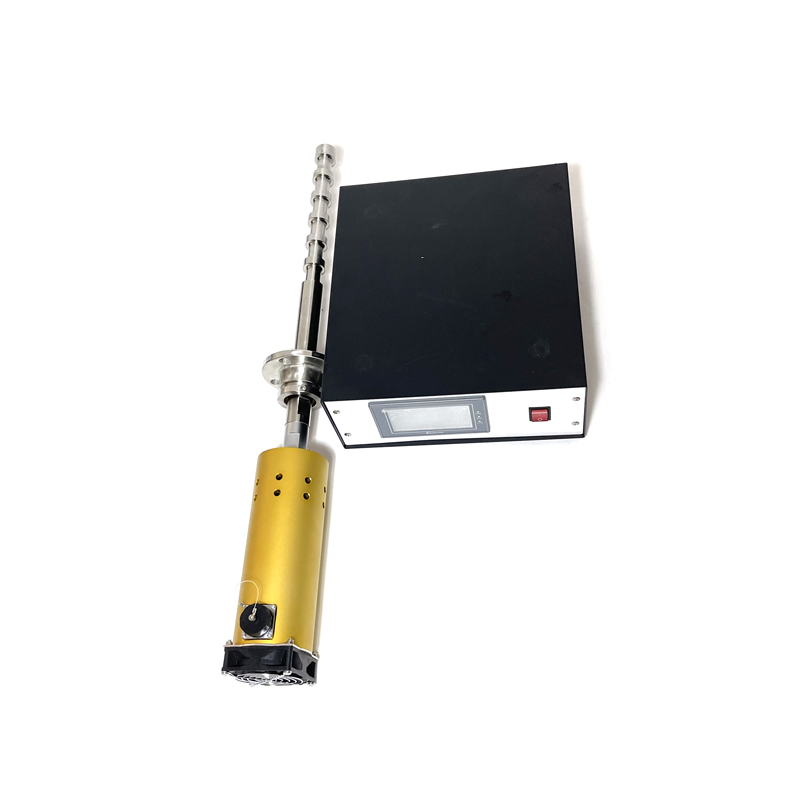

The ultrasonic system has stable amplitude and long working time. It adopts a nine section tool head design (industrial grade), and the radiation area increases by 2.5 times compared to traditional tool heads.

Adopting ultrasonic numerical control power supply (currently limited to industrial grade sonochemical systems), fully digital circuit control, with strong anti-interference ability.

Real time monitoring of frequency and power, adjustable power levels, with automatic alarm protection function, easy to operate

|

Tubular Equipment

Tip

|

Tubular Transducer

Tip

|

Frekvenciju

(Khz)

|

Ultrasound

Output(W)

|

Total Length

(Mm)

|

Diameter

(Mm)

|

Static Capacity

(pF±10%)

|

|

PU-UE1

|

US-61

|

15-28

|

1000

|

500

|

Φ50-55

|

68000

|

|

PU-UE5

|

US-25

|

15-28

|

1500

|

850

|

Φ50-55

|

68000

|

|

PU-UE6

|

US-16

|

15-28

|

2000

|

1100

|

Φ50-55

|

132000

|

Ultrazvučni transdukter,Ultrazvučni generator,Ultrazvučni čistač -SKSONIC

Ultrazvučni transdukter,Ultrazvučni generator,Ultrazvučni čistač -SKSONIC