Ultrasonic descaling device is an effective device that can be used to remove dirt from heat exchange equipment. Dirt is a poor conductor of heat, and the presence of dirt not only leads to a decrease in the heat transfer performance of heat exchange equipment, but also causes huge economic losses and energy waste. In the industrial world, chemical descaling methods are commonly used, but this method is costly, environmentally polluting, and requires dedicated management. Ultrasonic scale inhibition technology is a new technology developed in recent years, which has the advantages of high efficiency, high reliability, simple operation, and low operating cost. Compared with chemical descaling methods, ultrasonic descaling technology has no pollution to the environment and has good application prospects.

Ultrasonic descaling device is an effective device that can be used to remove dirt from heat exchange equipment. Dirt is a poor conductor of heat, and the presence of dirt not only leads to a decrease in the heat transfer performance of heat exchange equipment, but also causes huge economic losses and energy waste. In the industrial world, chemical descaling methods are commonly used, but this method is costly, environmentally polluting, and requires dedicated management. Ultrasonic scale inhibition technology is a new technology developed in recent years, which has the advantages of high efficiency, high reliability, simple operation, and low operating cost. Compared with chemical descaling methods, ultrasonic descaling technology has no pollution to the environment and has good application prospects.

Ultrasonic technology is widely used in fields such as boiler water treatment and equipment cleaning, and has achieved good results under the research of domestic scholars in various aspects. The ultrasonic anti scaling device has a dual function, which not only prevents scaling, but also allows for descaling operations, increasing the heat transfer coefficient by 0.6-0.8 times. The higher the power and frequency of ultrasound, the stronger the cavitation effect, thereby slowing down the scaling rate. Especially when the power is 1500W and the frequency is 28kHz, the anti scaling effect is more obvious.

Ultrasonic technology plays a significant role in industrial scale removal, and research has found that ultrasonic treatment can improve the scale removal effect by 2-8 times. Ultrasound has obvious scale inhibition ability. For example, treating hard water with 28kHz ultrasound for 2 seconds can effectively inhibit calcium carbonate scaling, with a scale inhibition rate of over 90%.

Ultrasound has a significant descaling effect, and the use of ultrasound at a frequency of 28kHz can delay the crystallization process of calcium carbonate, achieving a descaling efficiency of over 85%. Ultrasound has an impact on corrosion, scaling, and microbial growth in the circulating water system. After ultrasonic treatment, the concentration of calcium ions and total alkalinity in the solution significantly decrease, while the acidity and alkalinity of the solution slightly increase. The power and flow rate of ultrasound have an impact on the descaling effect. The research results indicate that the higher the power and flow rate of ultrasound, the better the descaling effect.

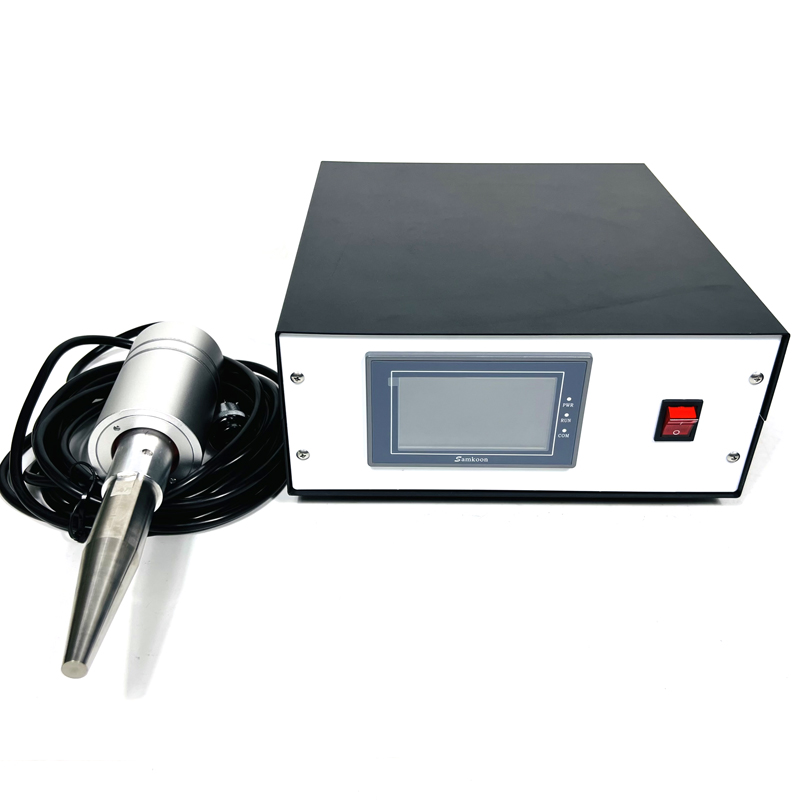

| Model | Power | Frequency | Weight |

| PLS-CG200W | 200W | 15-20KHZ | 20KG |

Ultrazvukový prevodník,Ultrazvukový generátor,Ultrazvukový čistič -SKSONIC

Ultrazvukový prevodník,Ultrazvukový generátor,Ultrazvukový čistič -SKSONIC