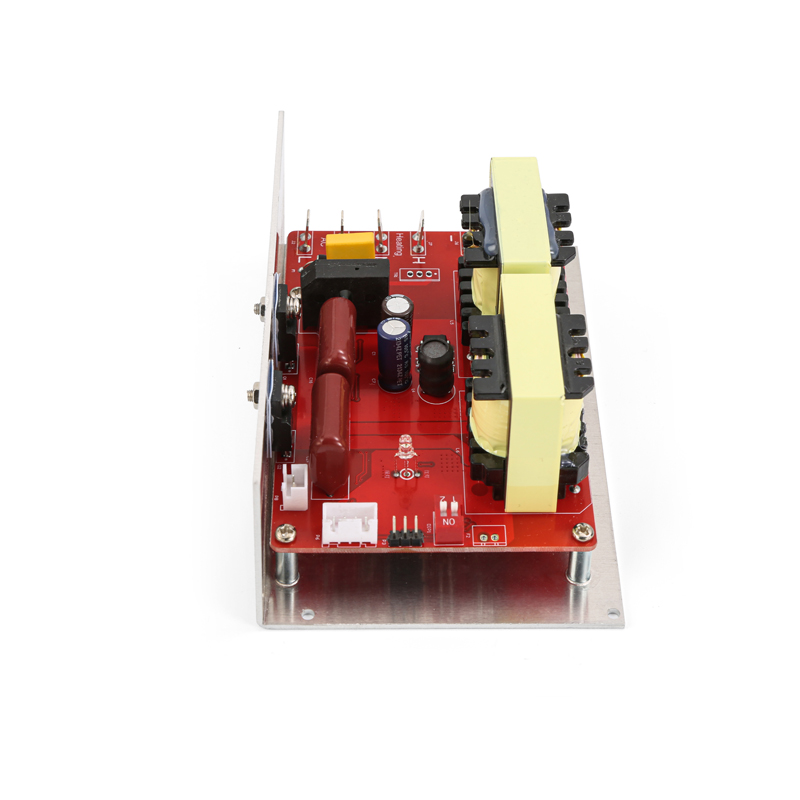

Characteristics of Ultrasonic Mechanical Drive Board Circuit Board

Characteristics of Ultrasonic Mechanical Drive Board Circuit Board

1. Efficient cleaning: The ultrasonic mechanical drive board circuit board utilizes the vibration energy of ultrasonic waves to quickly and effectively remove dirt and impurities on the surface of objects, greatly improving cleaning efficiency.

2. Environmental protection: The cleaning agents used for ultrasonic mechanical drive circuit boards are mostly water or alkaline aqueous solutions, which are more environmentally friendly compared to traditional organic solvent cleaning methods.

3. Low cost: The operating cost of ultrasonic mechanical drive circuit boards is relatively low, requiring only a small amount of cleaning agent and water, and the equipment has a long service life and low maintenance costs.

4. Wide application range: Ultrasonic mechanical drive board circuit board is suitable for various materials, shapes, and sizes of objects, especially for objects with complex shapes, multiple pores, narrow gaps, and other difficult to clean with traditional methods.

By improving the frequency and waveform of ultrasonic waves, as well as optimizing the ratio and usage of cleaning solution, the cleaning efficiency of ultrasonic mechanical drive board circuit boards can be further improved. By combining automation technology, sensor technology, and computer technology, intelligent control and management of ultrasonic mechanical drive circuit boards can be achieved, improving production efficiency and product quality. Design and produce ultrasonic mechanical drive board circuit boards that better meet practical needs according to different industries and needs, to meet the needs of various special application scenarios.

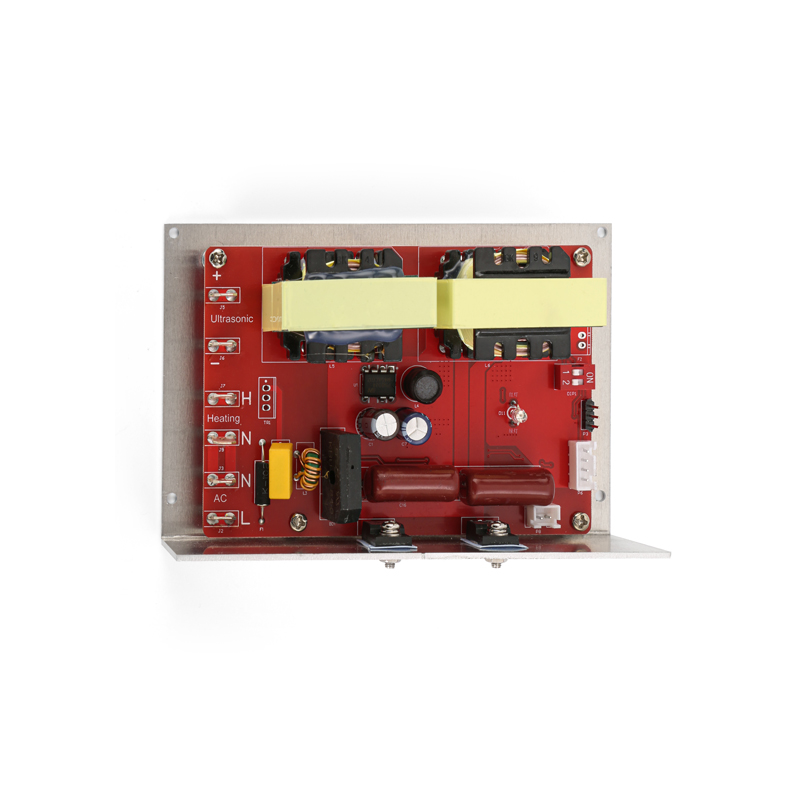

| Model | Power(W) | Frequency (khz) | Operating voltage | Maximum output current |

| PU-XLB50W | 50 | 25khz,28khz,33khz,40khz | AC110V/220V | 0.33A |

| PU-XLB100W | 100 | 25khz,28khz,33khz,40khz | AC110V/220V | 0.45A |

| PU-XLB150W | 150 | 25khz,28khz,33khz,40khz | AC110V/220V | 0.65A |