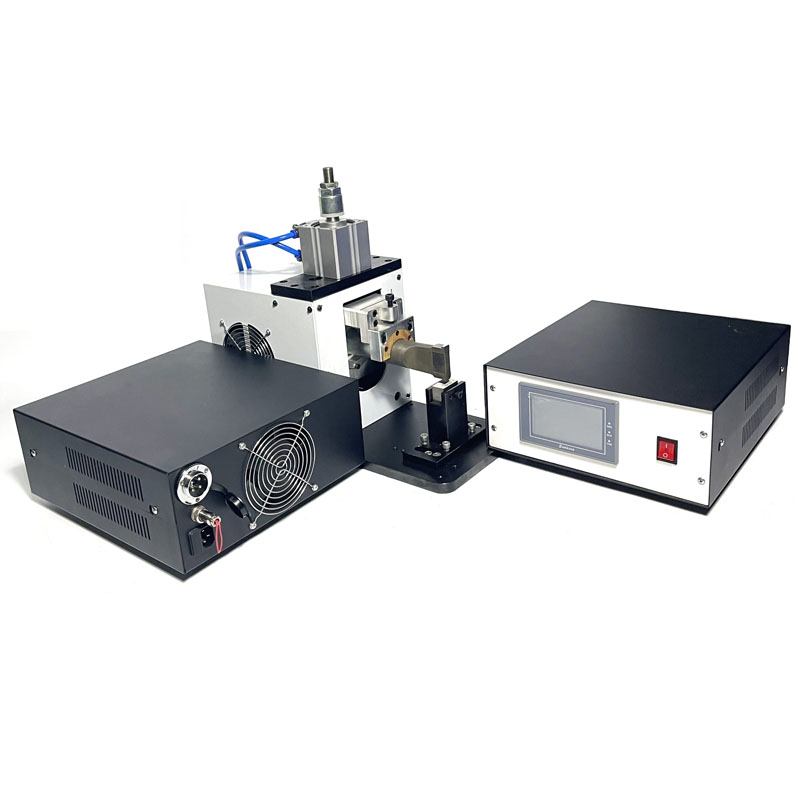

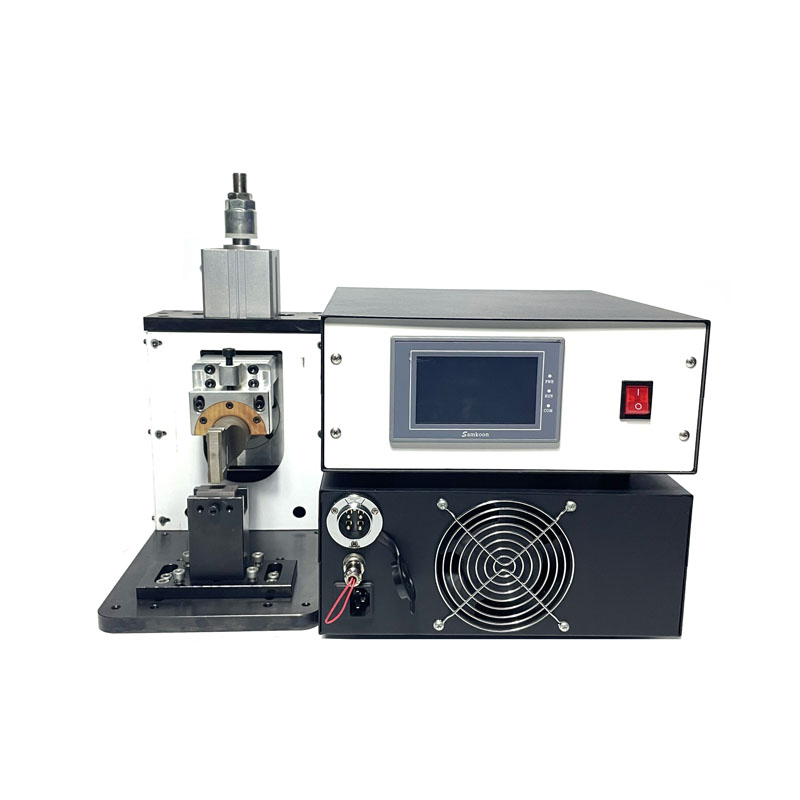

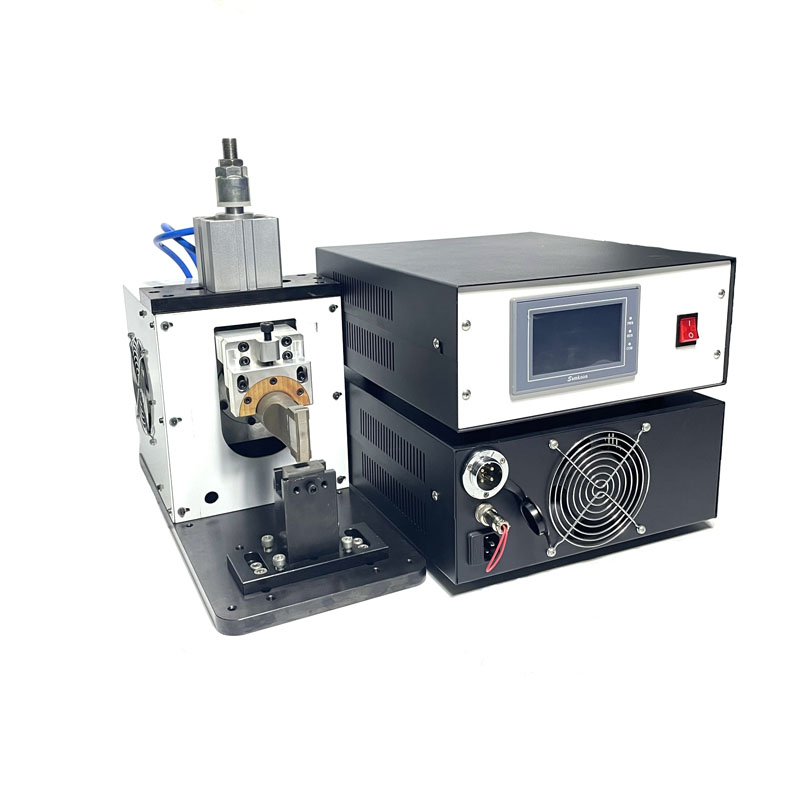

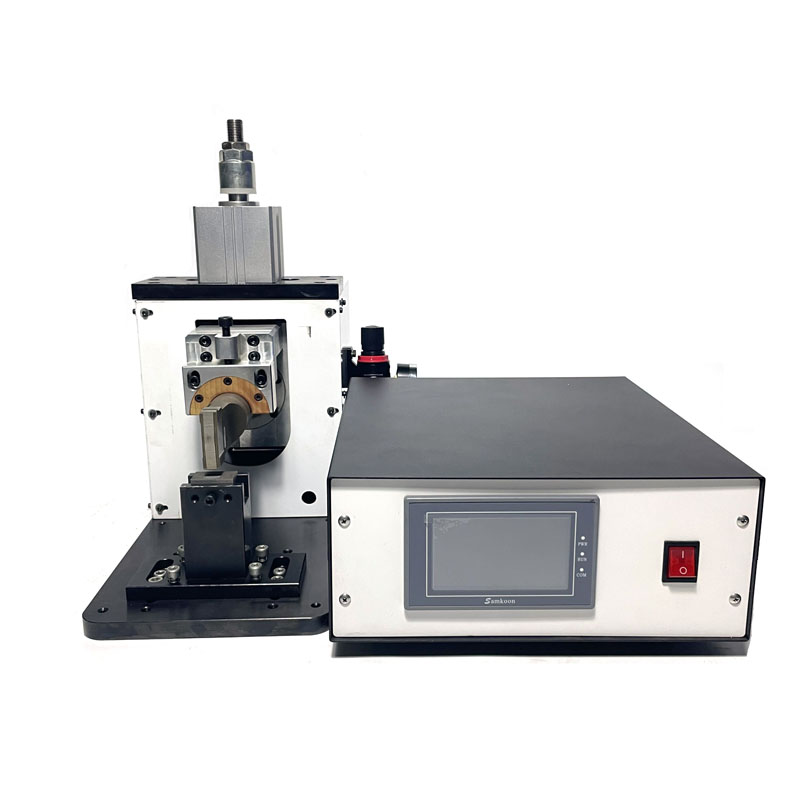

The working principle of metal ultrasonic welding machine:

The working principle of metal ultrasonic welding machine:

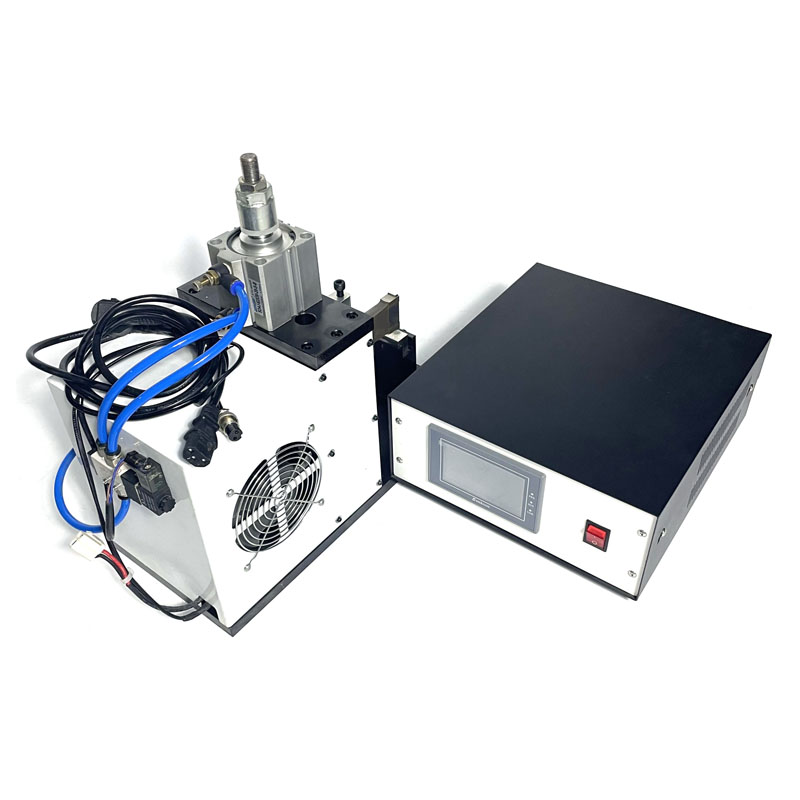

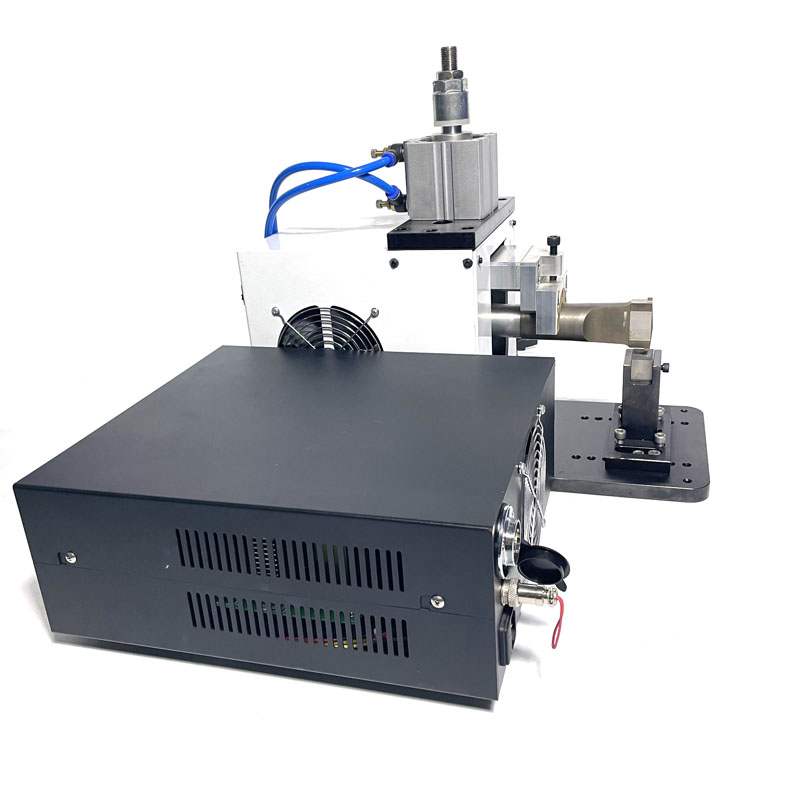

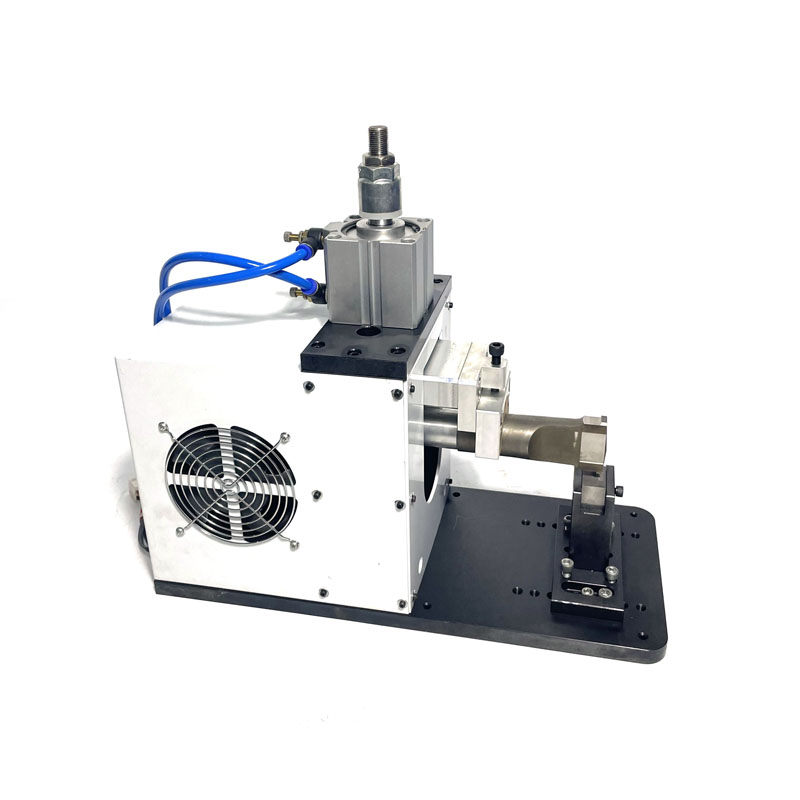

1. Using high-frequency oscillation signals to convert electrical signals into mechanical vibrations (such as rotation and reciprocating motion), and driving the compression device and transducer through the transmission system to generate ultrasonic vibration force;

2. A closed container composed of a compression device and a transducer;

3. Place workpieces or semi-finished products to be processed in the container;

4. The high-frequency oscillation signal is generated by the transducer and transmitted to the compression device;

5. The working head is driven by a compression device to perform linear reciprocating motion (i.e., a mobile working head);

6. A mold surface and fixture (i.e. fixed working head) that matches the workpiece are installed on the working head;

7. During work, the workpiece is fixed on a fixed working head through the mold surface or fixture for ultrasonic welding operation;

8. After completing a fusion process, release the mold surface and fixture to take out the workpiece to obtain the required product.

| Type | Power(W) | Frequency (KHz) |

| PU-MSW2000W | 2000W | 20KHZ |

| PU-MSW2600W | 2600W | 20KHZ |

| PU-MSW3200W | 3200W | 20KHZ |

| PU-MSW4000W | 4000W | 20KHZ |

| PU-MSW800W | 800W | 40KHZ |

Transdutor ultra-sônico,Gerador ultra-sônico,Limpador ultra-sônico -SKSONIC

Transdutor ultra-sônico,Gerador ultra-sônico,Limpador ultra-sônico -SKSONIC