High stability: When the ultrasonic generator is working, it generates 40KHz electromagnetic vibration, which is converted into mechanical vibration and transmitted to the cutting blade and the cutting material. Mechanical cutting is carried out, so there is no need for sharp edges. The blade wear is minimal, and the blade can be replaced on its own.

High stability: When the ultrasonic generator is working, it generates 40KHz electromagnetic vibration, which is converted into mechanical vibration and transmitted to the cutting blade and the cutting material. Mechanical cutting is carried out, so there is no need for sharp edges. The blade wear is minimal, and the blade can be replaced on its own.

Non pollution: When ultrasonic cutting, the temperature of the blade is below 50 ℃, and there is no smoke or odor generated, eliminating the risk of injury and fire during cutting.

Cutting neatly: Due to the high-frequency vibration of ultrasonic waves for cutting, the material will not adhere to the surface of the blade. When cutting, only a small amount of pressure is required, and fragile and soft materials will not deform or wear. The fabric cutting also automatically seals the edges, without causing edge collapse.

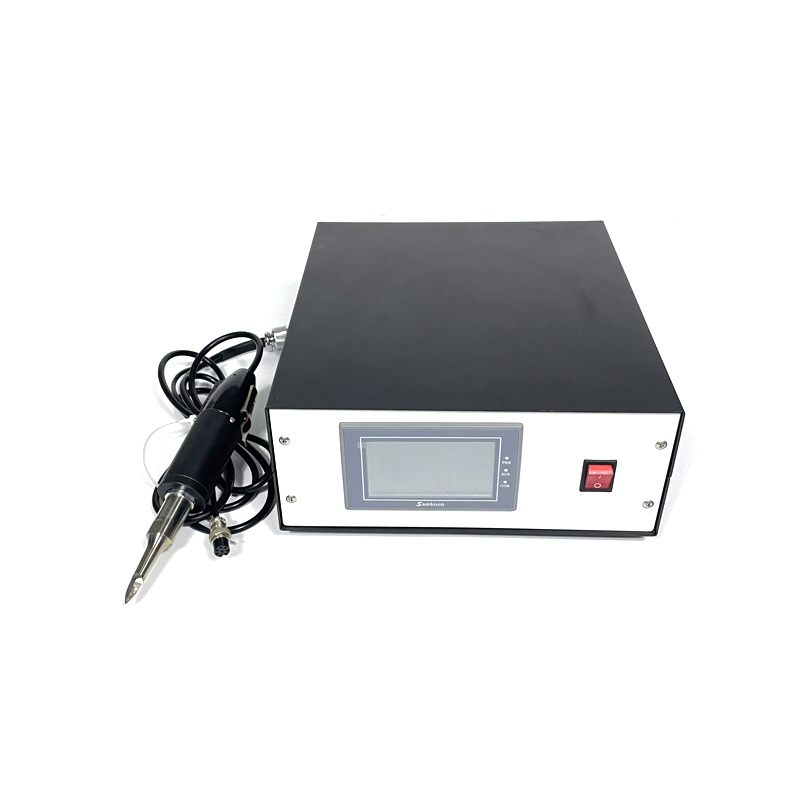

Simple operation: Connect the cutting knife to the ultrasonic generator, connect the generator to 220V mains power, open the switch to perform cutting, support handheld cutting, and equipped with an air-cooled interface.

Wide application range: Various textile materials and plastic sheets can be cut by ultrasound, such as natural fibers, synthetic fibers, non-woven fabrics, and knitted fabrics.

| Type | power (W) |

Frequency | Welding time | Contains |

| PU-QG100W | 100W | 30khz,35khz,40khz | 0.1-3sec | generator , transducer ,horn,head |

| PU-QG300W | 300W | 30khz,35khz,40khz | 0.1-3sec | generator , transducer ,horn,head |

| PU-QG500W | 500W | 30khz,35khz,40khz | 0.1-3sec | generator , transducer ,horn,head |