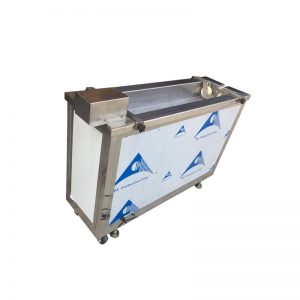

The mesh roller ultrasonic cleaning machine utilizes the vibration of ultrasonic waves and the strong scouring effect of cleaning solution to thoroughly remove pollutants from the surface of the mesh roller. Compared with traditional cleaning methods, ultrasonic cleaning has the following advantages:

The mesh roller ultrasonic cleaning machine utilizes the vibration of ultrasonic waves and the strong scouring effect of cleaning solution to thoroughly remove pollutants from the surface of the mesh roller. Compared with traditional cleaning methods, ultrasonic cleaning has the following advantages:

1. Good cleaning effect: Ultrasonic cleaning can thoroughly remove various pollutants on the surface of the mesh roller, including ink stains, glue stains, oil stains, etc., making the mesh roller look brand new.

2. Protecting the anilox roller: Traditional cleaning methods can easily cause damage to the anilox roller, while ultrasonic cleaning does not cause any damage to the surface of the anilox roller, thereby extending its service life.

3. Efficient and environmentally friendly: Ultrasonic cleaning not only has high efficiency, but also uses environmentally friendly cleaning solutions, reducing pollution to the environment and harm to human health.

4. Easy to operate: The ultrasonic cleaning machine for the mesh roller is simple and convenient. Simply put the mesh roller to be cleaned into the cleaning machine, add an appropriate amount of cleaning solution, and turn on the equipment.

|

Model |

Internal size |

Outsize mm |

Frequency (Khz) |

Power(W) |

Heating(W) |

Total power(W) |

voltage |

|

PLS-DQXJ-1006 |

280×210×210 |

320×250×350 |

20,28,33,40,80,130 |

300 |

1000 |

1300 |

220V |

|

PLS-DQXJ-1012 |

400×310×280 |

520×430×600 |

20,28,33,40,80,130 |

600 |

3000 |

3600 |

220V |

|

PLS-DQXJ-1018 |

490×360×320 |

610×480×675 |

20,28,33,40,80,130 |

900 |

3000 |

3900 |

220V |

|

PLS-DQXJ-1024 |

630×430×320 |

740×550×675 |

20,28,33,40,80,130 |

1200 |

4000 |

5200 |

220V |

|

PLS-DQXJ-1030 |

630×530×320 |

750×650×675 |

20,28,33,40,80,130 |

1500 |

4000 |

5500 |

220V |

|

PLS-DQXJ-1036 |

680×530×360 |

800×650×700 |

20,28,33,40,80,130 |

1800 |

5000 |

6800 |

220V |

|

PLS-DQXJ-1040 |

680×570×400 |

830×710×735 |

20,28,33,40,80,130 |

2000 |

5000 |

7000 |

220V |

|

Welcome OEM size enquire |

|||||||