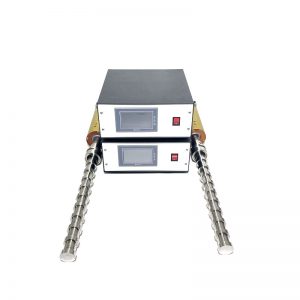

Compared with conventional methods, laboratory industrial ultrasonic stirring vibration rods have simpler ultrasonic equipment and lower production costs. In most cases, laboratory industrial ultrasonic stirring vibrating rods have fewer steps, lower temperatures, and simpler processes, making them suitable for solid-liquid mixing of target components.

The laboratory industrial ultrasonic stirring vibrating rod generates alternating high and low pressures in the exposed liquid. During the low-pressure cycle, ultrasound generates small vacuum bubbles in the liquid, which violently rupture during the high-pressure cycle. This phenomenon is called cavitation. The implosion of cavitating bubbles causes strong Fluid power shear forces. Shear force can fully mix reactants and shorten reaction time.

|

Tubular Equipment

Type

|

Tubular Transducer

Type

|

Frequency

(Khz)

|

Ultrasound

Output(W)

|

Total Length

(milímetro)

|

Diameter

(milímetro)

|

Static Capacity

(pF±10%)

|

|

PU-UE1

|

US-61

|

15-28

|

1000

|

500

|

Φ50-55

|

68000

|

|

PU-UE5

|

US-25

|

15-28

|

1500

|

850

|

Φ50-55

|

68000

|

|

PU-UE6

|

US-16

|

15-28

|

2000

|

1100

|

Φ50-55

|

132000

|

Transductor ultrasónico,Generador ultrasónico,Limpiador ultrasónico — SKSONIC

Transductor ultrasónico,Generador ultrasónico,Limpiador ultrasónico — SKSONIC