With the ultrasonic stripping method, when the ultrasonic extraction Graphene dispersion stripping vibrating rod equipment spreads in the liquid, the graphite slurry will produce high-frequency oscillation, and cavitation bubbles will be formed in the liquid phase. Because the size of graphite is much larger than the size of cavitation bubbles, the collapse of cavitation bubbles near graphite is asymmetric, resulting in high-speed micro jet pointing to the graphite surface, which will cause local damage to its surface. High frequency ultrasound makes graphite slurry vibrate at high frequency, and due to the difference of oscillation frequency, multiple layers are formed in the container, and graphite is continuously stripped into Graphene.

With the ultrasonic stripping method, when the ultrasonic extraction Graphene dispersion stripping vibrating rod equipment spreads in the liquid, the graphite slurry will produce high-frequency oscillation, and cavitation bubbles will be formed in the liquid phase. Because the size of graphite is much larger than the size of cavitation bubbles, the collapse of cavitation bubbles near graphite is asymmetric, resulting in high-speed micro jet pointing to the graphite surface, which will cause local damage to its surface. High frequency ultrasound makes graphite slurry vibrate at high frequency, and due to the difference of oscillation frequency, multiple layers are formed in the container, and graphite is continuously stripped into Graphene.

|

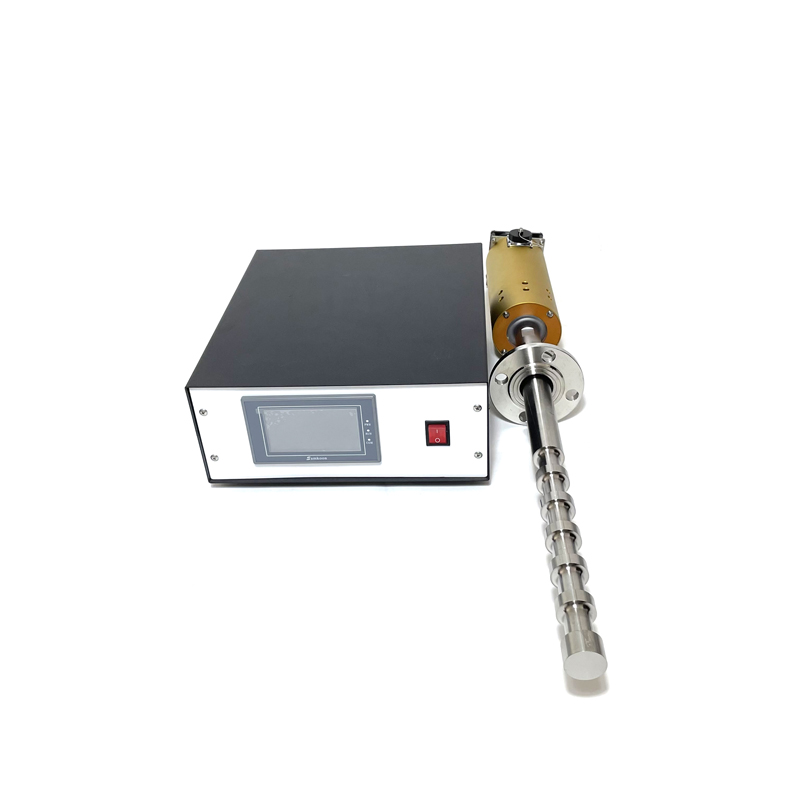

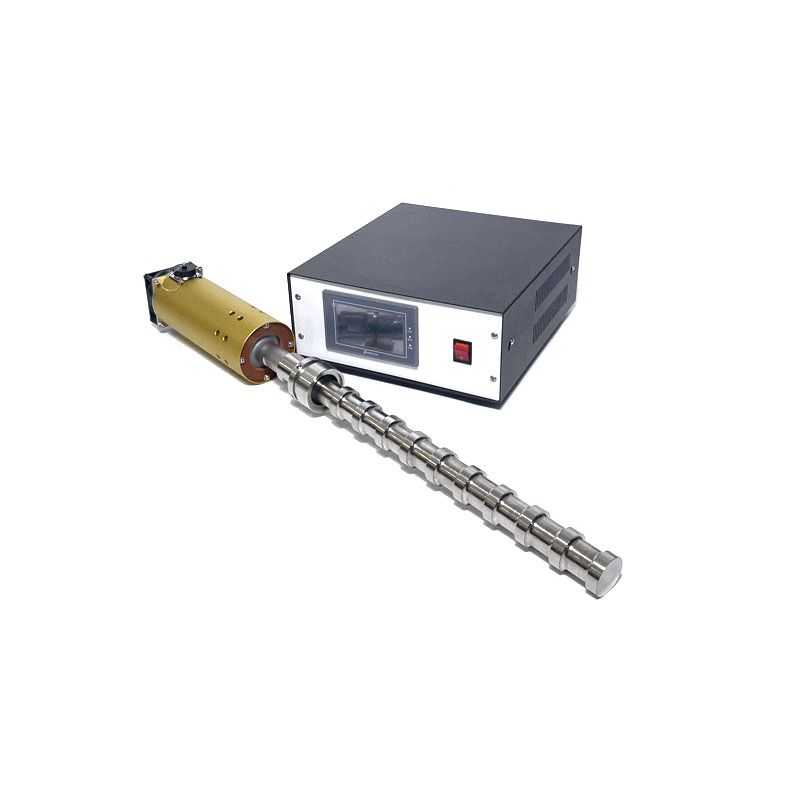

Tubular Equipment

Type

|

Tubular Transducer

Type

|

Frequency

(Khz)

|

Ultrasound

Output(W)

|

Total Length

(milímetro)

|

Diameter

(milímetro)

|

Static Capacity

(pF±10%)

|

|

PU-UE1

|

US-61

|

15-28

|

1000

|

500

|

Φ50-55

|

68000

|

|

PU-UE5

|

US-25

|

15-28

|

1500

|

850

|

Φ50-55

|

68000

|

|

PU-UE6

|

US-16

|

15-28

|

2000

|

1100

|

Φ50-55

|

132000

|

Transductor ultrasónico,Generador ultrasónico,Limpiador ultrasónico — SKSONIC

Transductor ultrasónico,Generador ultrasónico,Limpiador ultrasónico — SKSONIC