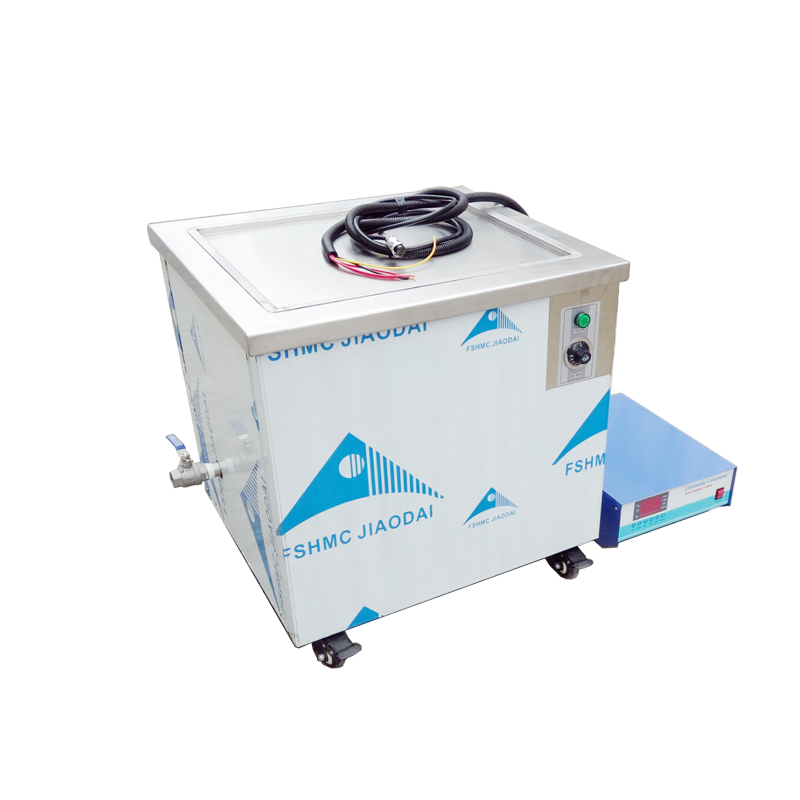

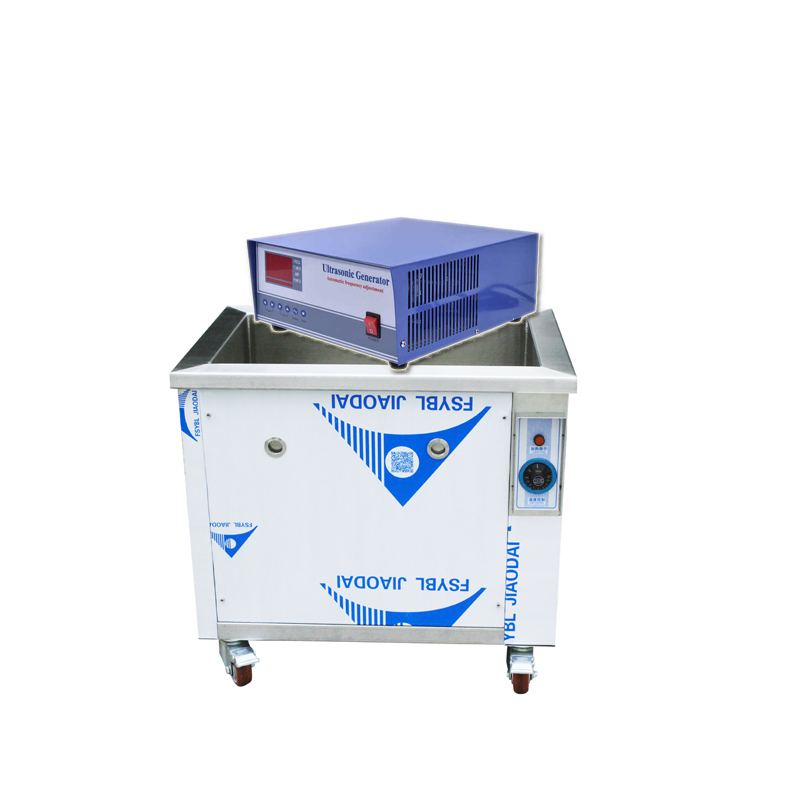

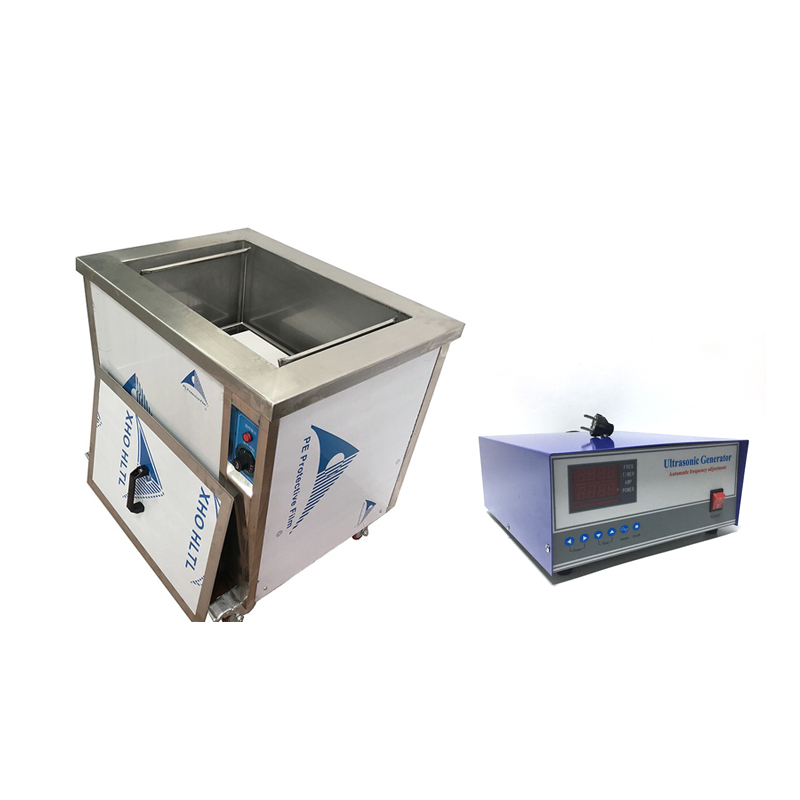

Product Introduction

Product Introduction

The principle of an ultrasonic cleaning machine is mainly to convert the sound energy of a power ultrasonic frequency source into mechanical vibration through a transducer. By cleaning the tank wall, the cleaning solution in the tank is subjected to ultrasonic radiation, allowing the micro bubbles in the liquid in the tank to maintain vibration under the action of sound waves. When the sound pressure or intensity reaches a certain level, bubbles will rapidly expand and then suddenly close again. During this process, the instant the bubble closes, a shock wave is generated, which repeatedly impacts the adsorbed substances and dirt on the surface of the cleaned part. Disrupting the adsorption of dirt on the surface of the cleaned part and causing fatigue damage to the dirt layer, resulting in detachment. Thus achieving the cleaning purpose.

| Type | Internal size L*W*H(mm) |

Frequency(Khz) | Power(W) | Heating(W) |

| PU-1006TT | 280×210×210 | 20,28,33,40,80,130 | 300 | 1000 |

| PU-1012TT | 400×310×280 | 20,28,33,40,80,130 | 600 | 3000 |

| PU-1018TT | 490×360×320 | 20,28,33,40,80,130 | 900 | 3000 |

| PU-1024TT | 630×430×320 | 20,28,33,40,80,130 | 1200 | 4000 |

| PU-1030TT | 630×530×320 | 20,28,33,40,80,130 | 1500 | 4000 |

| PU-1036TT | 680×530×360 | 20,28,33,40,80,130 | 1800 | 5000 |

| PU-1040TT | 680×570×400 | 20,28,33,40,80,130 | 2000 | 5000 |

| PU-1041TT | 730×570×450 | 20,28,33,40,80,130 | 2400 | 6000 |

| PU-1042TT | 790×670×510 | 20,28,33,40,80,130 | 3000 | 6000 |

| PU-1043TT | 850×770×570 | 20,28,33,40,80,130 | 4000 | 7000 |

| PU-1044ST | 910×820×620 | 20,28,33,40,80,130 | 5000 | 7000 |

| PU-1045TT | 960×870×680 | 20,28,33,40,80,130 | 8000 | 8000 |

| PU-1046TT | 1100×930×730 | 20,28,33,40,80,130 | 10000 | 8000 |