According to the cleaning process requirements, the split type ultrasonic vibration plate is injected with a cleaning solvent with a mixed ratio. Generally, the ratio of cleaning solution to water is 5-10%, and the optimal distance between the liquid level and the cylinder surface is about 80mm; Side mounted shock plate, the liquid level must exceed the top of the shock plate. The installation and layout of the split type ultrasonic vibration plate is flexible, and can be made into three types according to different needs: bottom shock, side shock, and top shock to adapt to various cleaning requirements.

According to the cleaning process requirements, the split type ultrasonic vibration plate is injected with a cleaning solvent with a mixed ratio. Generally, the ratio of cleaning solution to water is 5-10%, and the optimal distance between the liquid level and the cylinder surface is about 80mm; Side mounted shock plate, the liquid level must exceed the top of the shock plate. The installation and layout of the split type ultrasonic vibration plate is flexible, and can be made into three types according to different needs: bottom shock, side shock, and top shock to adapt to various cleaning requirements.

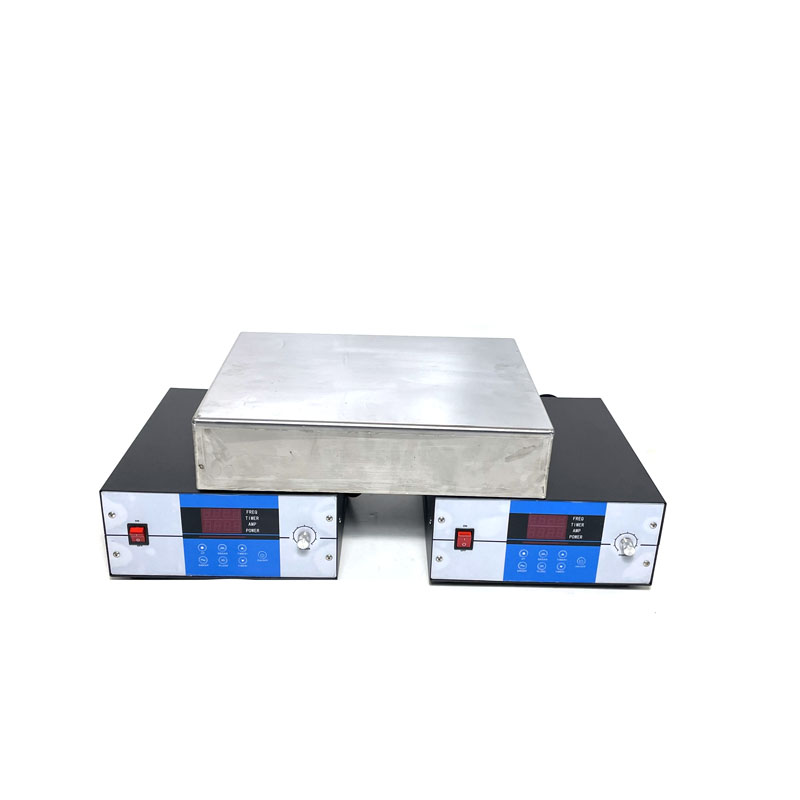

| Type | Diamention(mm) | Frequency(Khz) | Power(W) | Ultralyd transduser |

| PU-UITP300W | 300*190*100 | 25,28,33,40,80,130 | 300 | 6 |

| PU-UITP600W | 360*275*100 | 25,28,33,40,80,130 | 600 | 12 |

| PU-UITP1000W | 450*350*100 | 25,28,33,40,80,130 | 1000 | 20 |

| PU-UITP1200W | 470*380*100 | 25,28,33,40,80,130 | 1200 | 24 |

| PU-UITP1500W | 520*450*100 | 25,28,33,40,80,130 | 1500 | 30 |

| PU-UITP1800W | 560*450*100 | 25,28,33,40,80,130 | 1800 | 36 |

| PU-UITP2000W | 650*450*100 | 25,28,33,40,80,130 | 2000 | 40 |

| PU-UITP2400W | 740*520*100 | 25,28,33,40,80,130 | 2400 | 48 |

| PU-UITP3000W | 820*540*100 | 25,28,33,40,80,130 | 3000 | 60 |

| PU-UITP5000W | 1200*590*100 | 25,28,33,40,80,130 | 5000 | 100 |

| OEM Ultrasonic Immersible Transducer Pack(Size, Frequency,Power) | ||||

Ultralyd transduser,Ultralyd Generator,Ultralyd renere -SKSONIC

Ultralyd transduser,Ultralyd Generator,Ultralyd renere -SKSONIC