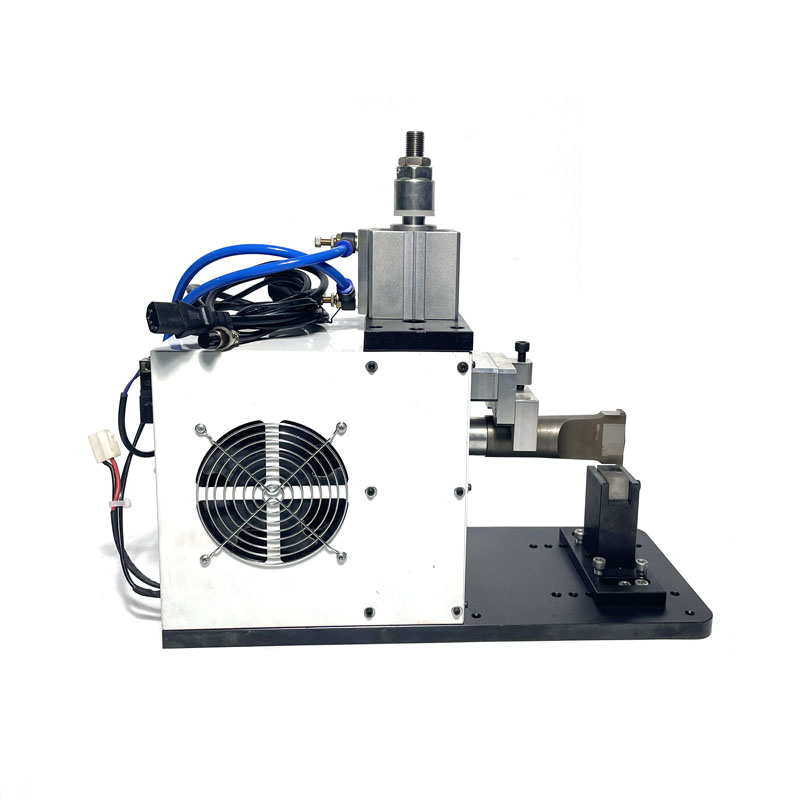

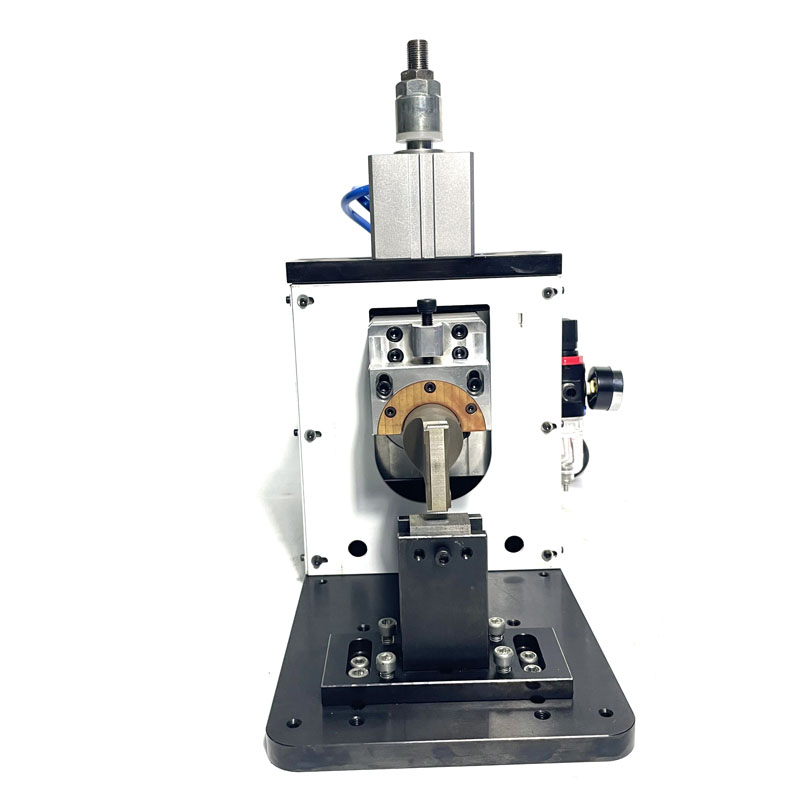

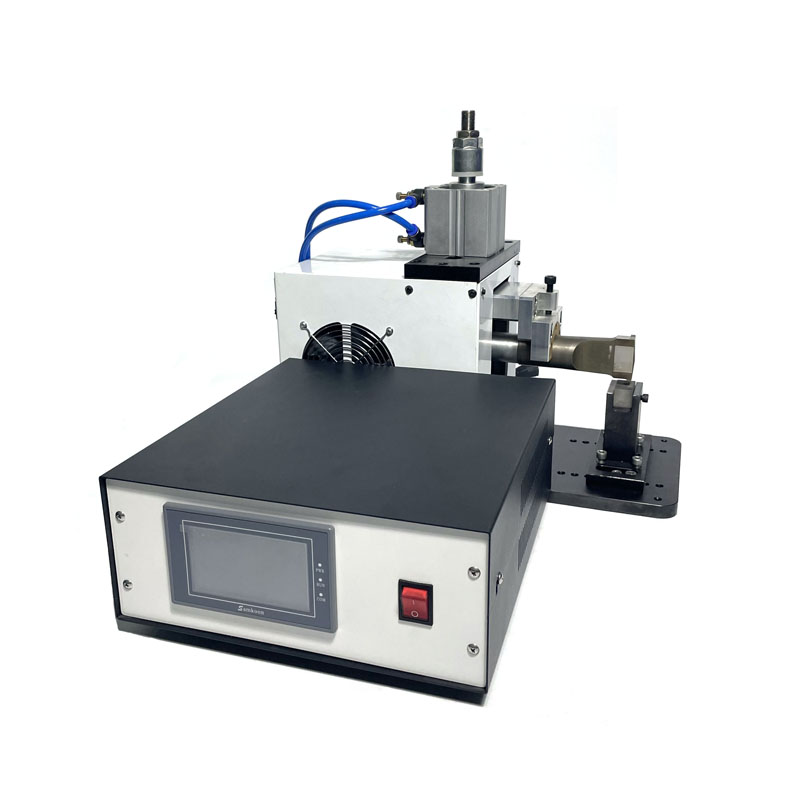

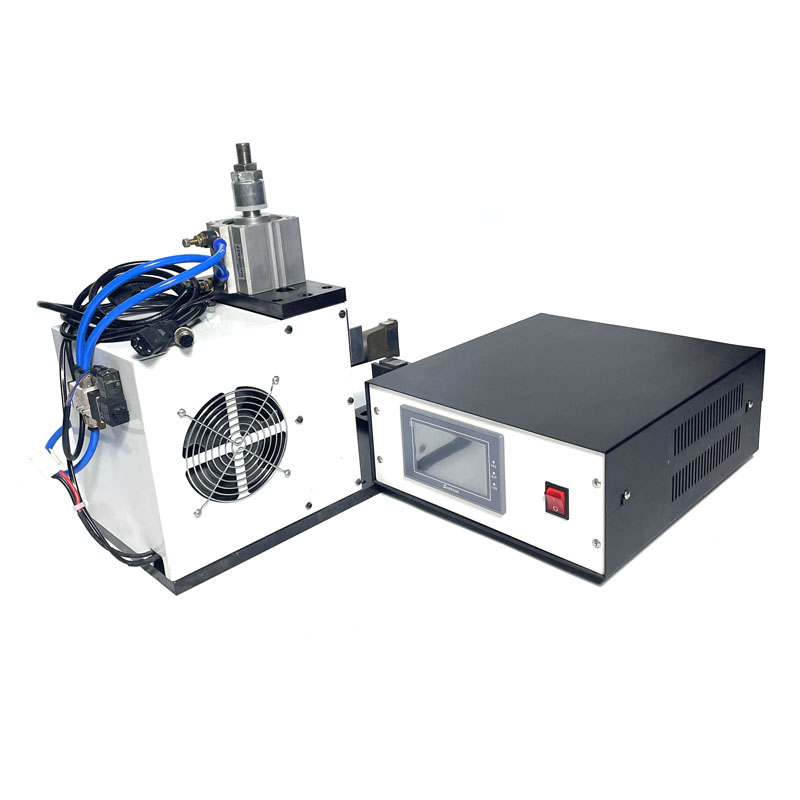

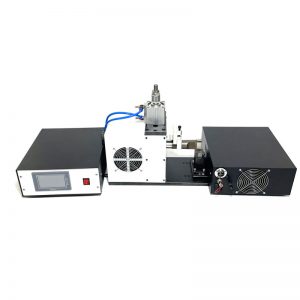

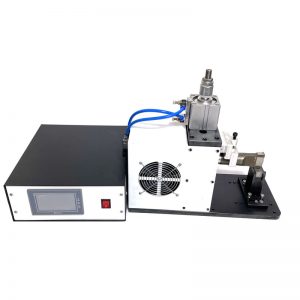

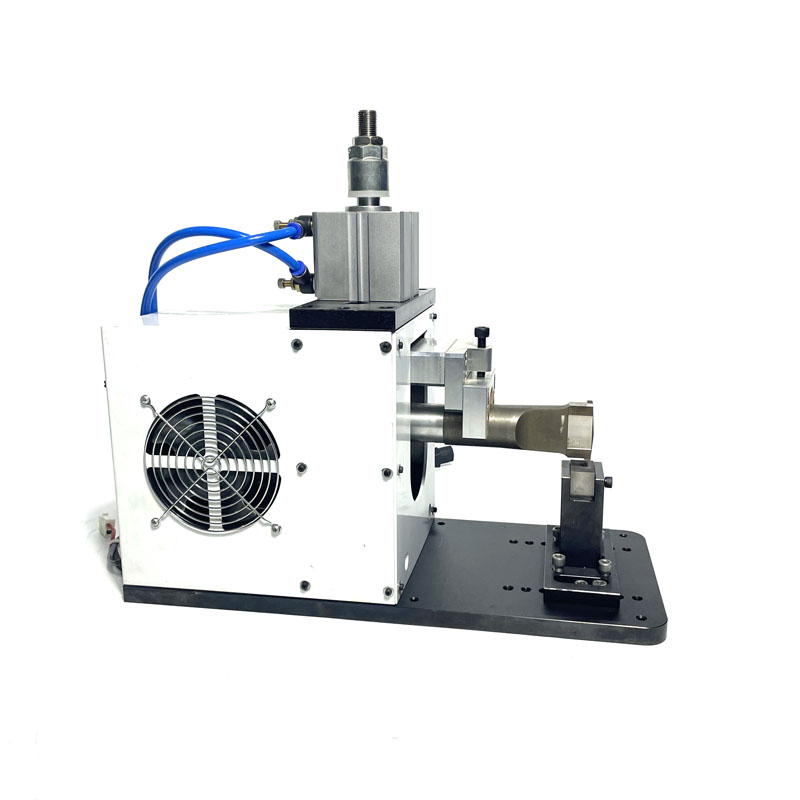

Ultrasonic wave metal spot welder: It is similar to friction welding, but with the difference that the ultrasonic welding time is very short and the temperature is lower than recrystallization; It is also different from pressure welding because the static pressure applied is much smaller than that of pressure welding. It is generally believed that in the initial stage of ultrasonic welding, the oxide on the metal surface is subjected to tangential vibration, and the protruding parts of the rough surface undergo repeated micro welding and damage, resulting in an increase in contact area and an increase in temperature in the welding zone, leading to plastic deformation at the interface of the welded part. In this way, under the action of contact pressure, solder joints are formed when they are close to the distance at which atomic gravity can act. Long welding time or excessive ultrasonic amplitude can cause a decrease in welding strength or even damage.

Ultrasonic wave metal spot welder: It is similar to friction welding, but with the difference that the ultrasonic welding time is very short and the temperature is lower than recrystallization; It is also different from pressure welding because the static pressure applied is much smaller than that of pressure welding. It is generally believed that in the initial stage of ultrasonic welding, the oxide on the metal surface is subjected to tangential vibration, and the protruding parts of the rough surface undergo repeated micro welding and damage, resulting in an increase in contact area and an increase in temperature in the welding zone, leading to plastic deformation at the interface of the welded part. In this way, under the action of contact pressure, solder joints are formed when they are close to the distance at which atomic gravity can act. Long welding time or excessive ultrasonic amplitude can cause a decrease in welding strength or even damage.

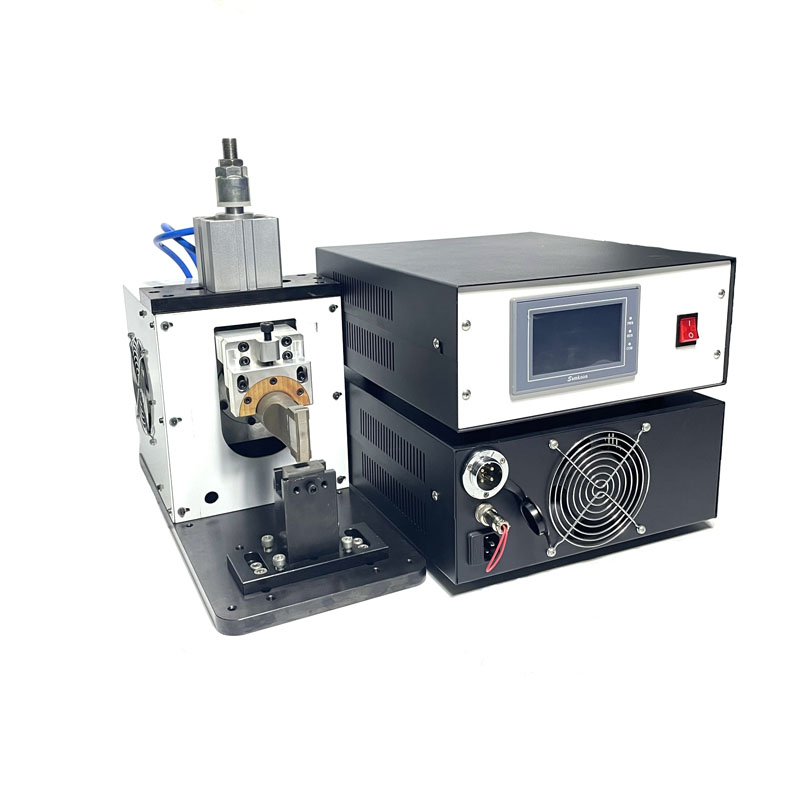

| Yam | hwj huam(W) | zauv (KHz) |

| PU-MSW2000W | 2000W | 20KHZ |

| PU-MSW2600W | 2600W | 20KHZ |

| PU-MSW3200W | 3200W | 20KHZ |

| PU-MSW4000W | 4000W | 20KHZ |

| PU-MSW800W | 800W | 40KHZ |

Ultrasonic Transducer,Ultrasonic Generator,Ultrasonic Cleaner-SKSONIC

Ultrasonic Transducer,Ultrasonic Generator,Ultrasonic Cleaner-SKSONIC