Ultrasound is an elastic mechanical vibration wave that is fundamentally different from electromagnetic waves. Because electromagnetic waves propagate in a vacuum, ultrasonic waves must propagate through the medium, forming the entire process of expansion and compression when passing through the medium.

Ultrasound is an elastic mechanical vibration wave that is fundamentally different from electromagnetic waves. Because electromagnetic waves propagate in a vacuum, ultrasonic waves must propagate through the medium, forming the entire process of expansion and compression when passing through the medium.

In liquid, the expansion process forms negative pressure. If the ultrasonic energy is strong enough, the expansion process will generate bubbles or tear the liquid into very small holes. These holes instantly close, generating an instantaneous pressure of up to 3000MPa upon closure, known as cavitation, and the entire process takes place at 400 degrees Celsius μ Complete within s.

Cavitation refines the substance and makes lotion, accelerates the target ingredients to enter the solvent, and improves the extraction rate. In addition to cavitation, many secondary effects of ultrasound also facilitate the transfer and extraction of target components.

The important significance of the phenomenon of cavitation lies in the reaction that occurs when a bubble ruptures. At some points, bubbles no longer absorb ultrasonic energy and produce implosion. The gas and steam in bubbles or cavities undergo rapid adiabatic compression, generating extremely high temperatures and pressures.

The volume of bubbles is extremely small compared to the total volume of the liquid, so the generated heat is instantly dissipated and does not have a significant impact on environmental conditions. The cooling rate after the rupture of the cavity bubble is estimated to be about 1010 ℃/s.

Ultrasonic holes provide unique interactions between energy and matter, resulting in the formation of free radicals and other components under high temperature and pressure.

In pure liquids, when a hole ruptures, it always remains spherical due to the same surrounding conditions; However, close to the solid boundary, the rupture of the hole is non-uniform, generating a high-speed liquid jet, converting the potential energy of the expanding bubble into the kinetic energy of the liquid jet, moving within the bubble and penetrating the bubble wall.

The impact force of jet flow on the solid surface is very strong, which can cause great damage to the impact zone, resulting in a highly active fresh surface. The impact force generated by the deformation of ruptured bubbles on the surface is several times greater than that generated by bubble resonance.

The above effects of ultrasound are very effective in extracting various target components from different types of samples.

The application of ultrasound generates high temperature and pressure on the contact surface between organic solvents and solid matrices, coupled with the oxidation energy of free radicals generated by ultrasound decomposition, providing high extraction energy.

|

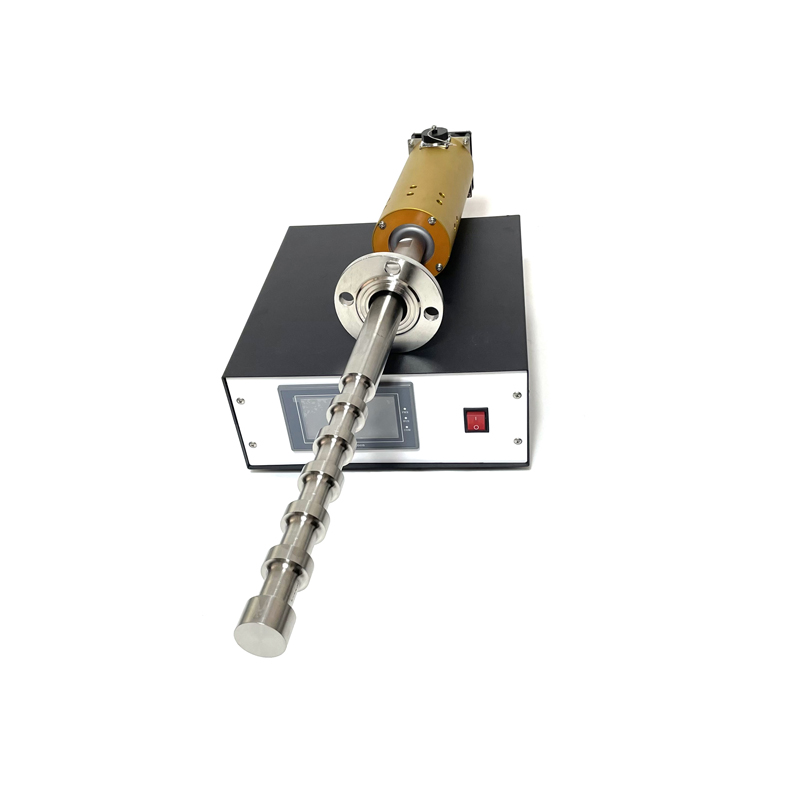

Tubular Equipment

Yam

|

Tubular Transducer

Yam

|

zauv

(KHz)

|

Ultrasound

Output(W)

|

Total Length

(mm)

|

Diameter

(mm)

|

Static Capacity

(pF±10%)

|

|

PU-UE1

|

US-61

|

15-28

|

1000

|

500

|

Φ50-55

|

68000

|

|

PU-UE5

|

US-25

|

15-28

|

1500

|

850

|

Φ50-55

|

68000

|

|

PU-UE6

|

US-16

|

15-28

|

2000

|

1100

|

Φ50-55

|

132000

|

Ultrasonic Transducer,Ultrasonic Generator,Ultrasonic Cleaner-SKSONIC

Ultrasonic Transducer,Ultrasonic Generator,Ultrasonic Cleaner-SKSONIC