A general term for handheld ultrasonic welding and processing equipment, usually including ultrasonic bead nailing machines, ultrasonic hot drilling machines, plastic welding machines, and ultrasonic cutting machines. It can be used in a single handheld or installed on a machine, and the tool head or workpiece can be controlled by a computer to move in the X-Y-Z direction, forming a fully automatic ultrasonic device.

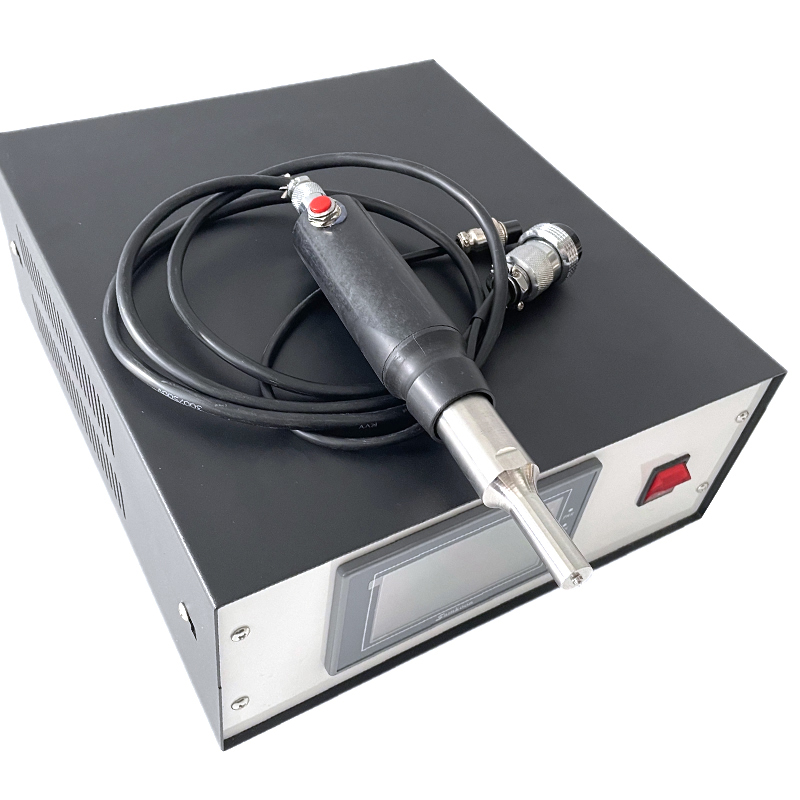

Handheld ultrasonic spot welding machine

Ultrasonic spot welding has significant advantages over traditional processes such as adhesive bonding, hot pressing, or screw fastening, such as high production efficiency, good welding quality, environmental protection, and energy conservation. The handheld ultrasonic welding machine can also be used for welding, riveting of thermoplastic products, as well as inlaying and edge pressing processes between metal and plastic parts. The process of replacing organic melting point adhesive has been completed, which has the characteristics of low energy consumption, high efficiency, no deformation, no pollution, firm welding, and convenient operation.

| Jenis | Kuasa(W) | Kekerapan (Khz) |

| PLS-DHJ-300 | 300W | 15KHz/20khz/28khz/40khz |

| PLS-DHJ-500 | 500W | 15KHz/20khz/28khz/40khz |

| PLS-DHJ-800 | 800W | 15KHz/20khz/28khz/40khz |

| PLS-DHJ-900 | 900W | 15KHz/20khz |

| PLS-DHJ-1000 | 1000W |

15KHz/20khz |

Transducer Ultrasonik,Penjana Ultrasonik,Pembersih Ultrasonik -SKSONIC

Transducer Ultrasonik,Penjana Ultrasonik,Pembersih Ultrasonik -SKSONIC