The advantages of ultrasonic cutting

The advantages of ultrasonic cutting

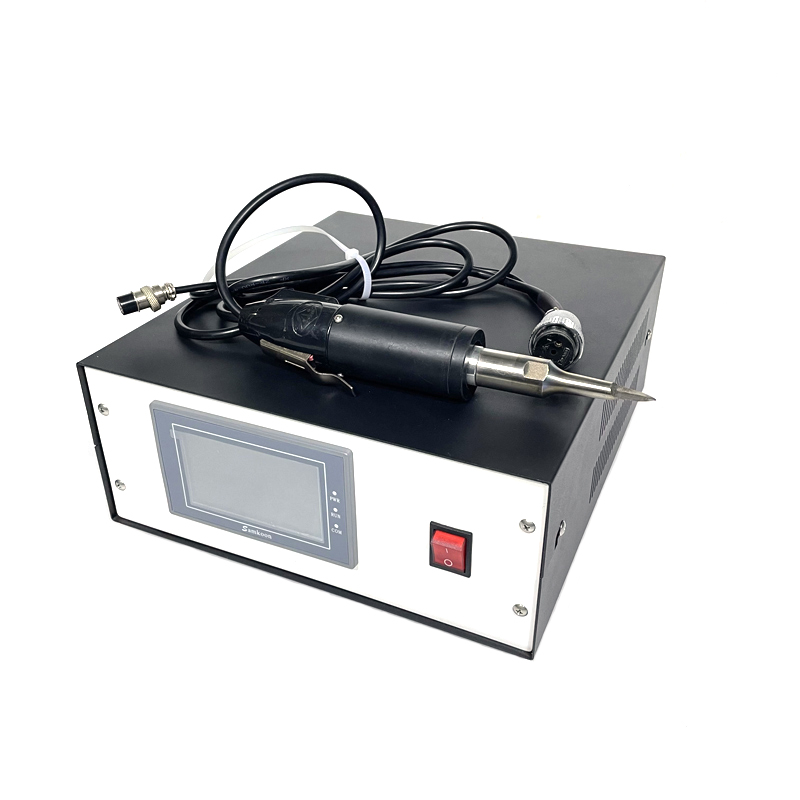

1. Can adopt air-cooled and water-cooled designs to adapt to various working conditions and environments

2. The cutting speed is greatly improved, and the efficiency is more than 10 times higher than traditional cutting knives

3. Using high-power ultrasonic transducers as vibration components to ensure long-term stable operation

4. The variety of cutting tools is complete, and cutting tools with relevant shapes can also be customized according to customer processes

5. Can cut various products that are difficult to cut with ordinary cutting tools, solving production and processing difficulties

6. High hardness blades can be installed, and cutting blades can be replaced, reducing usage costs

7. Easy to install and use, with almost no changes to the original cutting process

8. High cutting accuracy and good cutting surface smoothness

| Type | power (W) |

Frequency | Welding time | Contains |

| PU-QG100W | 100W | 30khz,35khz,40khz | 0.1-3sec | generator , transducer ,horn,head |

| PU-QG300W | 300W | 30khz,35khz,40khz | 0.1-3sec | generator , transducer ,horn,head |

| PU-QG500W | 500W | 30khz,35khz,40khz | 0.1-3sec | generator , transducer ,horn,head |