The principle of digital ultrasonic circuit board power supply is to use the vibration energy of ultrasonic waves in liquid to generate impact force and cavitation effect, thereby achieving cleaning effect. Specifically, when ultrasound propagates in liquids, it generates sound pressure, forming a powerful impact force that can quickly remove stains and impurities from the surface of objects. At the same time, ultrasound can also produce cavitation effects in liquids, that is, a large number of tiny bubbles are generated under the action of sound pressure. These bubbles rapidly expand and rupture under the action of sound pressure, producing stronger impact force and further enhancing the cleaning effect.

The principle of digital ultrasonic circuit board power supply is to use the vibration energy of ultrasonic waves in liquid to generate impact force and cavitation effect, thereby achieving cleaning effect. Specifically, when ultrasound propagates in liquids, it generates sound pressure, forming a powerful impact force that can quickly remove stains and impurities from the surface of objects. At the same time, ultrasound can also produce cavitation effects in liquids, that is, a large number of tiny bubbles are generated under the action of sound pressure. These bubbles rapidly expand and rupture under the action of sound pressure, producing stronger impact force and further enhancing the cleaning effect.

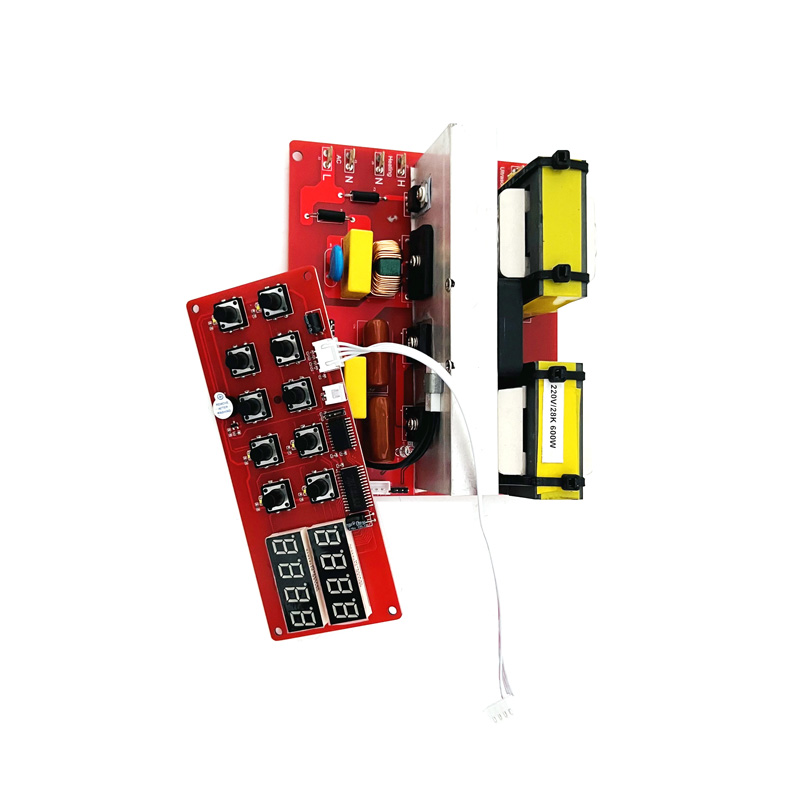

Application of Digital Ultrasonic Circuit Board Power Supply

1. Industrial field: Digital ultrasonic circuit board power supplies are widely used in the industrial field, such as cleaning mechanical parts, removing wax from electroplated parts, and cleaning spray boards in the chemical fiber industry. It can quickly and effectively remove various stubborn stains and impurities, improve product quality and production efficiency.

2. Home field: Digital ultrasonic circuit board power supply is also widely used in the home field, such as cleaning tableware, jewelry, glasses, etc. It can not only quickly remove stains and impurities, but also perform meticulous cleaning and care on some delicate items.

3. Laboratory field: In the laboratory, the digital ultrasonic cleaning power supply can be used for cleaning various experimental equipment, such as test tubes, beakers, culture dishes, etc. Due to its efficient cleaning effect and easy operation, it can greatly reduce the burden on experimental personnel and improve experimental efficiency.

The higher the power, the stronger the impact force generated by the power supply of the digital ultrasonic circuit board, and the better the cleaning effect. However, the power level also determines the power consumption and noise level, so it is necessary to choose the appropriate power level according to actual needs. Different items require different cleaning methods and parameter settings, so when choosing a digital ultrasonic cleaning power supply, it is necessary to consider its functional diversity, such as whether it supports cleaning modes of different frequencies and times. This can better meet different cleaning needs.

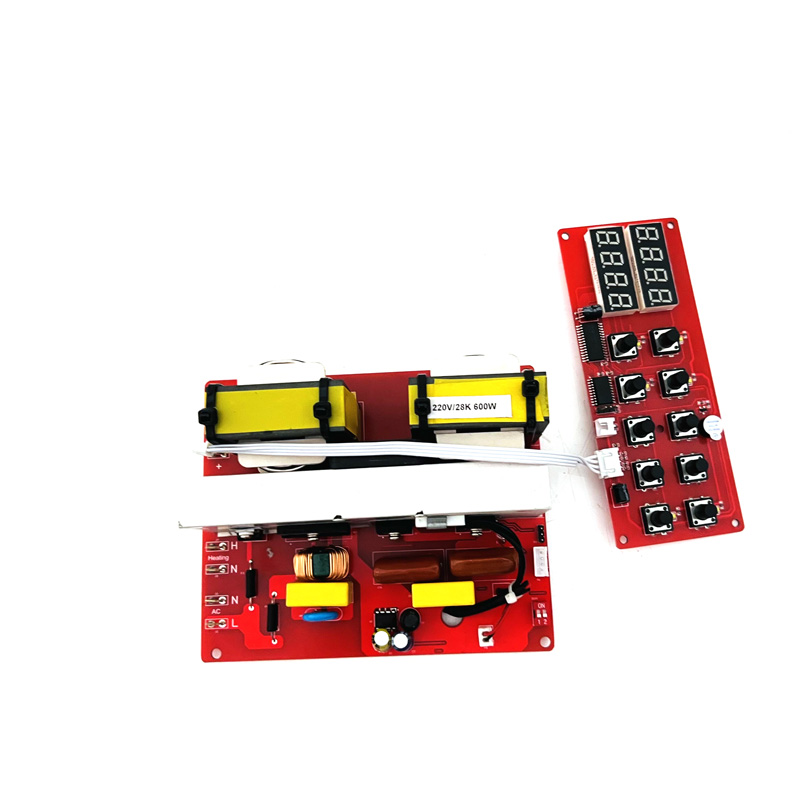

|

Model |

Power |

Frequency |

Voltage |

|

PLS-WDLB200W |

200W |

17khz,20khz,25khz,28khz,33khz,40khz,50khz,54khz, 68khz,80khz,100khz,120khz,135khz,165khz,200khz |

110V/120V/220V/240V |

|

PLS-WDLB300W |

300W |

17khz,20khz,25khz,28khz,33khz,40khz,50khz,54khz, 68khz,80khz,100khz,120khz,135khz |

110V/120V/220V/240V |

|

PLS-WDLB400W |

400W |

17khz,20khz,25khz,28khz,33khz,40khz |

110V/120V/220V/240V |

|

PLS-WDLB500W |

500W |

17khz,20khz,25khz,28khz,33khz,40khz |

110V/120V/220V/240V |

|

PLS-WDLB600W |

600W |

17khz,20khz,25khz,28khz,33khz,40khz |

110V/120V/220V/240V |