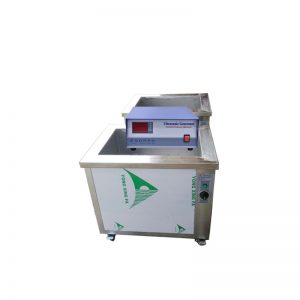

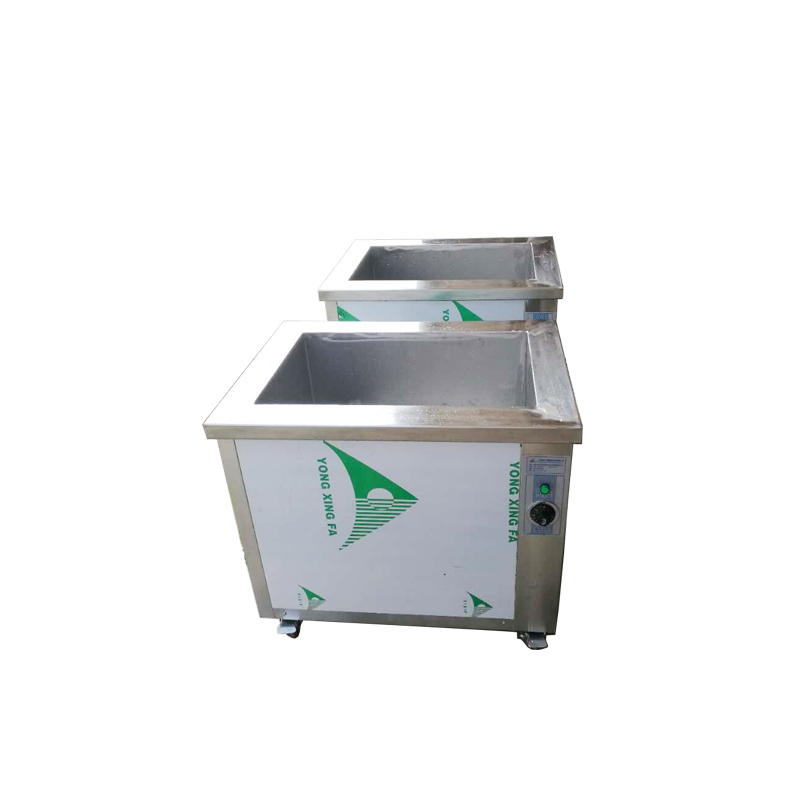

High frequency ultrasonic cleaning machines are widely used for cleaning various mechanical parts, such as gears, bearings, pistons, sns.. The surface of these parts often contains residual substances such as cutting fluid and grinding debris. The high-frequency vibration of ultrasound can quickly and effectively remove these impurities. Secondly, high-frequency ultrasonic cleaning machines are also suitable for cleaning optical components, such as lenses, optical lenses, prisms, sns.. These parts often have residual substances such as grinding paste and grease on the surface. By utilizing the high-frequency vibration of ultrasound, these impurities can be quickly removed, improving the high transmittance of optical components and the ultrasonic surface cleaning machine. It is also suitable for cleaning electronic parts. The surface of electronic parts often contains oxides, impurities, and other substances that can affect the performance and service life of electronic parts. The use of high-frequency ultrasonic cleaning machines can quickly remove these impurities, improving the performance and service life of electronic components.

High frequency ultrasonic cleaning machines are widely used for cleaning various mechanical parts, such as gears, bearings, pistons, sns.. The surface of these parts often contains residual substances such as cutting fluid and grinding debris. The high-frequency vibration of ultrasound can quickly and effectively remove these impurities. Secondly, high-frequency ultrasonic cleaning machines are also suitable for cleaning optical components, such as lenses, optical lenses, prisms, sns.. These parts often have residual substances such as grinding paste and grease on the surface. By utilizing the high-frequency vibration of ultrasound, these impurities can be quickly removed, improving the high transmittance of optical components and the ultrasonic surface cleaning machine. It is also suitable for cleaning electronic parts. The surface of electronic parts often contains oxides, impurities, and other substances that can affect the performance and service life of electronic parts. The use of high-frequency ultrasonic cleaning machines can quickly remove these impurities, improving the performance and service life of electronic components.

|

Model |

Internal size |

Outsize mm |

Frequency (Khz) |

Power(W) |

Heating(W) |

Total power(W) |

voltage |

|

PLS-DQXJ-1006 |

280×210×210 |

320×250×350 |

20,28,33,40,80,130 |

300 |

1000 |

1300 |

220V |

|

PLS-DQXJ-1012 |

400×310×280 |

520×430×600 |

20,28,33,40,80,130 |

600 |

3000 |

3600 |

220V |

|

PLS-DQXJ-1018 |

490×360×320 |

610×480×675 |

20,28,33,40,80,130 |

900 |

3000 |

3900 |

220V |

|

PLS-DQXJ-1024 |

630×430×320 |

740×550×675 |

20,28,33,40,80,130 |

1200 |

4000 |

5200 |

220V |

|

PLS-DQXJ-1030 |

630×530×320 |

750×650×675 |

20,28,33,40,80,130 |

1500 |

4000 |

5500 |

220V |

|

PLS-DQXJ-1036 |

680×530×360 |

800×650×700 |

20,28,33,40,80,130 |

1800 |

5000 |

6800 |

220V |

|

PLS-DQXJ-1040 |

680×570×400 |

830×710×735 |

20,28,33,40,80,130 |

2000 |

5000 |

7000 |

220V |

|

Welcome OEM size enquire |

|||||||

Ultrasonic Transducer,Ultrasonic Generator,Ultrasonic madio -SKSONIC

Ultrasonic Transducer,Ultrasonic Generator,Ultrasonic madio -SKSONIC