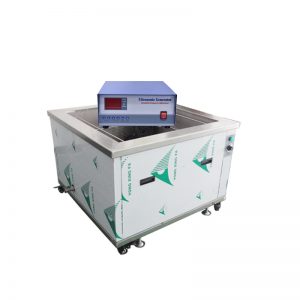

High frequency ultrasonic cleaning machines have already occupied an important position in industrial production due to their excellent cleaning effect. Its unique cleaning method, which generates a strong cavitation effect, brings faster and more thorough cleaning solutions to many industries.

High frequency ultrasonic cleaning machines have already occupied an important position in industrial production due to their excellent cleaning effect. Its unique cleaning method, which generates a strong cavitation effect, brings faster and more thorough cleaning solutions to many industries.

Under the action of high-frequency ultrasound, tiny bubbles in the cleaning solution rapidly vibrate and rupture, a process vividly known as the “cavitation effect”. The instantaneous high pressure and high temperature generated by this effect cause difficult to remove impurities such as dirt and oil on the surface of the cleaned object to be rapidly decomposed and peeled off under strong physical and chemical effects. Compared with traditional cleaning methods, high-frequency ultrasonic cleaning machines not only have a faster cleaning speed, but also have a more thorough cleaning effect. It is not limited by the shape and surface complexity of objects, and can penetrate into the tiny gaps and depressions of objects, removing difficult to reach dirt one by one. In addition, ultrasonic cleaning can achieve comprehensive cleaning of the object without damaging its surface, greatly improving cleaning quality and efficiency.

The application range of high-frequency ultrasonic cleaning machines is wide, covering almost all fields that require fine cleaning, from precision mechanical parts to electronic components, from medical devices to jewelry. Its emergence not only improves the cleanliness of industrial production, but also brings more convenience to people’s daily lives. High frequency ultrasonic cleaning machines, with their unique cavitation effect, have achieved faster and more thorough cleaning effects, bringing revolutionary changes to modern industrial production and daily life.

|

Model |

Internal size |

Outsize mm |

Frequency (Khz) |

Power(W) |

Heating(W) |

Total power(W) |

voltage |

|

PLS-DQXJ-1006 |

280×210×210 |

320×250×350 |

20,28,33,40,80,130 |

300 |

1000 |

1300 |

220V |

|

PLS-DQXJ-1012 |

400×310×280 |

520×430×600 |

20,28,33,40,80,130 |

600 |

3000 |

3600 |

220V |

|

PLS-DQXJ-1018 |

490×360×320 |

610×480×675 |

20,28,33,40,80,130 |

900 |

3000 |

3900 |

220V |

|

PLS-DQXJ-1024 |

630×430×320 |

740×550×675 |

20,28,33,40,80,130 |

1200 |

4000 |

5200 |

220V |

|

PLS-DQXJ-1030 |

630×530×320 |

750×650×675 |

20,28,33,40,80,130 |

1500 |

4000 |

5500 |

220V |

|

PLS-DQXJ-1036 |

680×530×360 |

800×650×700 |

20,28,33,40,80,130 |

1800 |

5000 |

6800 |

220V |

|

PLS-DQXJ-1040 |

680×570×400 |

830×710×735 |

20,28,33,40,80,130 |

2000 |

5000 |

7000 |

220V |

|

Welcome OEM size enquire |

|||||||