With the continuous development of industrial production, cleaning equipment plays an increasingly important role in industrial production. As an efficient and environmentally friendly cleaning equipment, high-frequency industrial ultrasonic cleaning machines are widely used in various industrial fields. High frequency industrial ultrasonic cleaning machines mainly use the cavitation and vibration effects of ultrasound to clean the surface of objects. Specifically, when ultrasonic waves act on the cleaning solution, high-frequency vibrations and small bubbles are generated in the solution. These bubbles generate a huge impact force during the rapid expansion and contraction process, which strongly washes the surface of the object to achieve the purpose of cleaning.

With the continuous development of industrial production, cleaning equipment plays an increasingly important role in industrial production. As an efficient and environmentally friendly cleaning equipment, high-frequency industrial ultrasonic cleaning machines are widely used in various industrial fields. High frequency industrial ultrasonic cleaning machines mainly use the cavitation and vibration effects of ultrasound to clean the surface of objects. Specifically, when ultrasonic waves act on the cleaning solution, high-frequency vibrations and small bubbles are generated in the solution. These bubbles generate a huge impact force during the rapid expansion and contraction process, which strongly washes the surface of the object to achieve the purpose of cleaning.

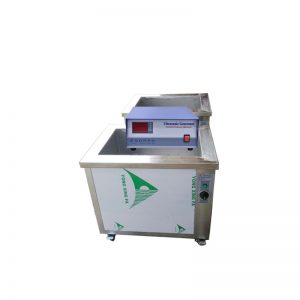

Characteristics of high-frequency industrial ultrasonic cleaning machine:

1. Efficient cleaning: High frequency industrial ultrasonic cleaning machine can quickly remove dirt and impurities on the surface of objects in a short period of time, improving cleaning efficiency.

2. Environmental protection: This cleaning machine adopts a non chemical cleaning method, which does not require the use of any chemical reagents, thus avoiding secondary pollution.

3. Wide application range: suitable for cleaning the surfaces of various materials, shapes, and sizes of objects, such as metal, glass, ceramics, plastics, etc.

4. Strong controllability: The cleaning effect can be controlled by adjusting parameters such as ultrasonic frequency, power, and cleaning time.

5. Easy to operate: The high-frequency industrial ultrasonic cleaning machine has a simple structure, convenient operation, and easy maintenance.

|

Model |

Internal size |

Outsize mm |

Frequency (Khz) |

Power(W) |

Heating(W) |

Total power(W) |

voltage |

|

PLS-DQXJ-1006 |

280×210×210 |

320×250×350 |

20,28,33,40,80,130 |

300 |

1000 |

1300 |

220V |

|

PLS-DQXJ-1012 |

400×310×280 |

520×430×600 |

20,28,33,40,80,130 |

600 |

3000 |

3600 |

220V |

|

PLS-DQXJ-1018 |

490×360×320 |

610×480×675 |

20,28,33,40,80,130 |

900 |

3000 |

3900 |

220V |

|

PLS-DQXJ-1024 |

630×430×320 |

740×550×675 |

20,28,33,40,80,130 |

1200 |

4000 |

5200 |

220V |

|

PLS-DQXJ-1030 |

630×530×320 |

750×650×675 |

20,28,33,40,80,130 |

1500 |

4000 |

5500 |

220V |

|

PLS-DQXJ-1036 |

680×530×360 |

800×650×700 |

20,28,33,40,80,130 |

1800 |

5000 |

6800 |

220V |

|

PLS-DQXJ-1040 |

680×570×400 |

830×710×735 |

20,28,33,40,80,130 |

2000 |

5000 |

7000 |

220V |

|

Welcome OEM size enquire |

|||||||