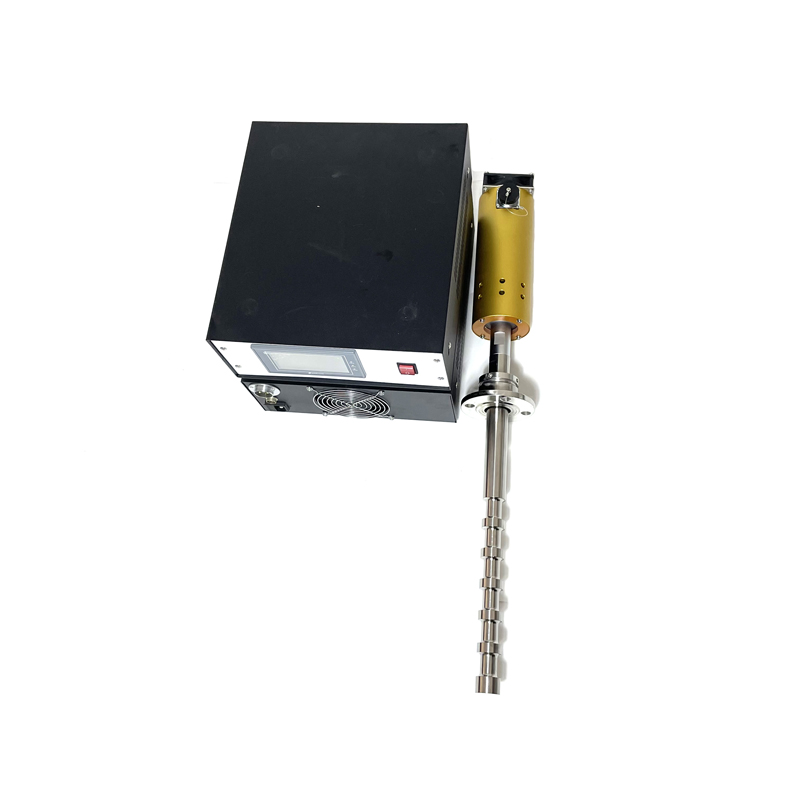

Characteristics of industrial ultrasonic emulsification and dispersion extraction equipment:

Characteristics of industrial ultrasonic emulsification and dispersion extraction equipment:

1. Efficient and fast: Industrial ultrasonic emulsification dispersion extraction equipment adopts high-frequency vibration and emulsification dispersion technology, which can complete the extraction process in a short time, greatly improving production efficiency.

2. Energy saving and environmental protection: The equipment adopts ultrasonic technology, which does not require heating or adding chemical reagents, reducing energy consumption and environmental pollution.

3. Easy to operate: The device has a compact structure, simple operation, easy maintenance, and reduces usage costs.

4. Wide applicability: suitable for the extraction and dispersion of various materials, such as chemical raw materials, food additives, pharmaceutical intermediates, etc.

The equipment adopts high-frequency vibration and emulsification dispersion technology, which can quickly extract the effective components from the material and improve the extraction efficiency. The equipment can evenly disperse small particles in the material, making the product more stable and uniform, and improving product quality. Industrial ultrasonic emulsification and dispersion extraction equipment, as an advanced extraction equipment, has advantages such as high efficiency, speed, and environmental protection, and has broad application prospects in fields such as chemical industry, food, medicine, and pesticides. With the continuous progress of technology and the increasing requirements for environmental protection, it is believed that this type of equipment will play a more important role in future production.

|

Tubular Equipment

Type

|

Tubular Transducer

Type

|

Frequency

(KHz)

|

Ultrasound

Output(W)

|

Total Length

(mm)

|

Diameter

(mm)

|

Static Capacity

(pF±10%)

|

|

PU-UE1

|

US-61

|

15-28

|

1000

|

500

|

Φ50-55

|

68000

|

|

PU-UE5

|

US-25

|

15-28

|

1500

|

850

|

Φ50-55

|

68000

|

|

PU-UE6

|

US-16

|

15-28

|

2000

|

1100

|

Φ50-55

|

132000

|