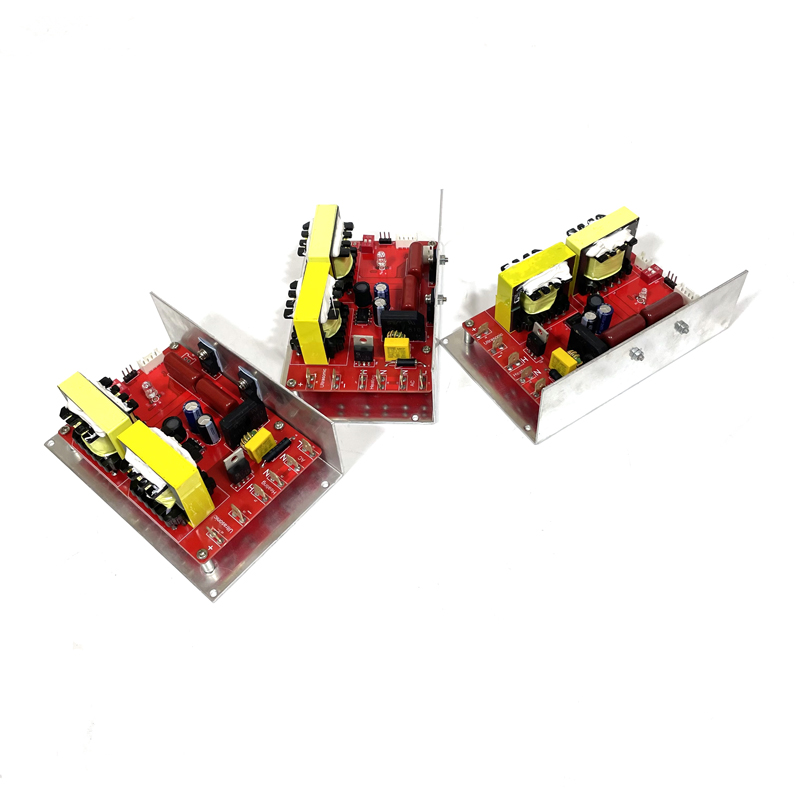

In the manufacturing process of ultrasonic PCB circuit boards, it is first necessary to design circuit diagrams and component layouts, and then use CAD software to convert the design into PCB board diagrams. Næstur, place the metal foil on the PCB board and use ultrasonic energy to connect the metals together. This manufacturing method can avoid the use of toxic chemicals, making it more environmentally friendly.

Ultrasonic PCB circuit boards have many advantages. Firstly, it has high reliability because metal connections are completed instantly and do not generate any residual stress, thus ensuring the long-term reliability of the circuit board. Secondly, the manufacturing efficiency of ultrasonic PCB circuit boards is very high, and a large number of circuit boards can be manufactured in a short period of time. In addition, this manufacturing method can also save a lot of materials and energy, making it very environmentally friendly.

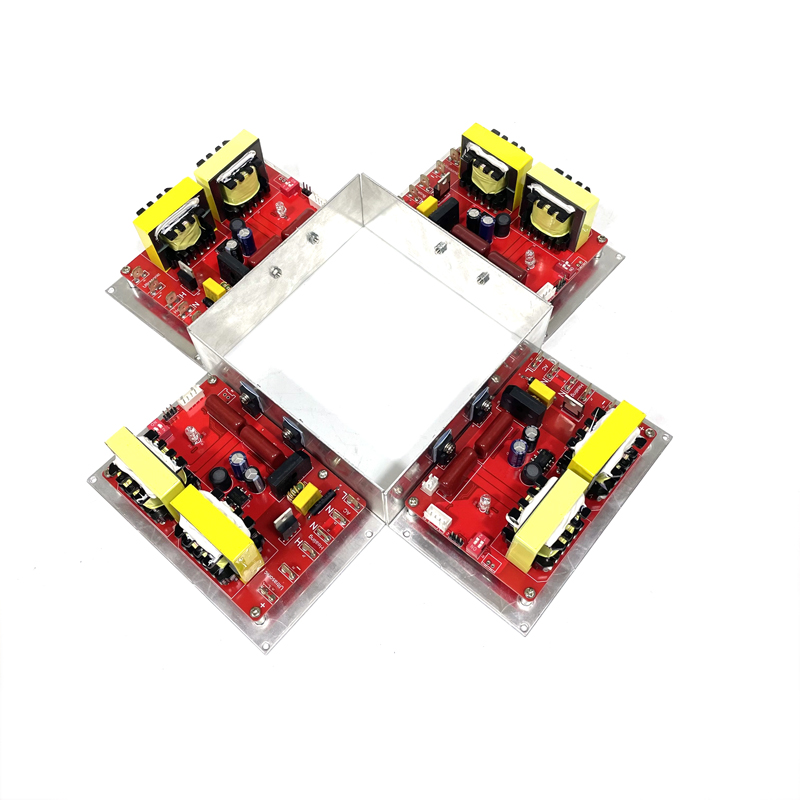

| Líkan | Vald(W) | Tíðni (Khz) | Rekstrarspenna | Hámarksafköst núverandi |

| PU-XLB50W | 50 | 25Khz,28Khz,33Khz,40Khz | AC110V/220V | 0.33A |

| PU-XLB100W | 100 | 25Khz,28Khz,33Khz,40Khz | AC110V/220V | 0.45A |

| PU-XLB150W | 150 | 25Khz,28Khz,33Khz,40Khz | AC110V/220V | 0.65A |

Ultrasonic Transducer,Ultrasonic rafall,Ultrasonic Hreinsiefni -SKSONIC

Ultrasonic Transducer,Ultrasonic rafall,Ultrasonic Hreinsiefni -SKSONIC