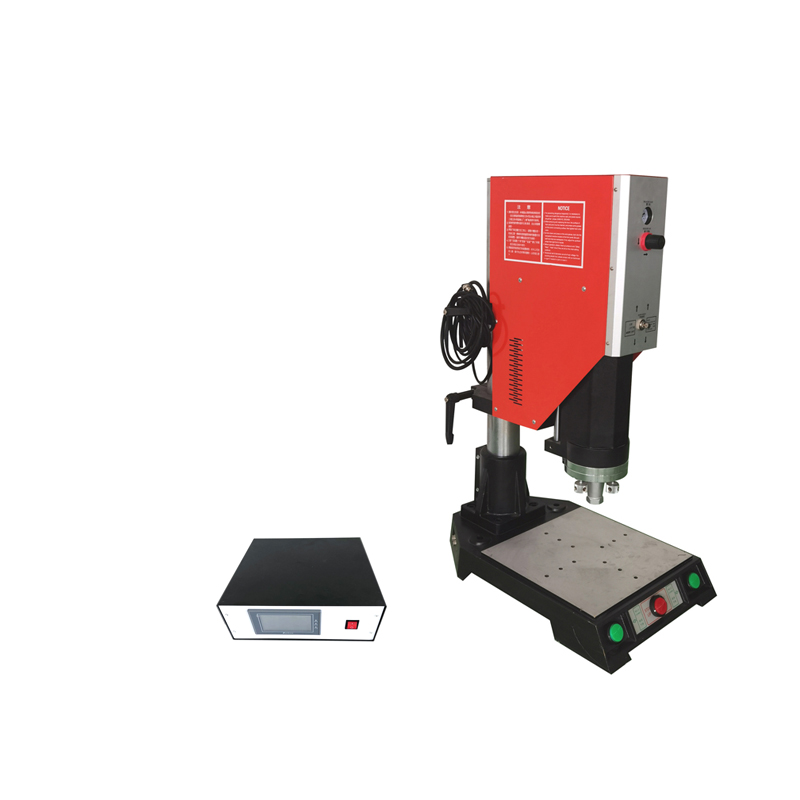

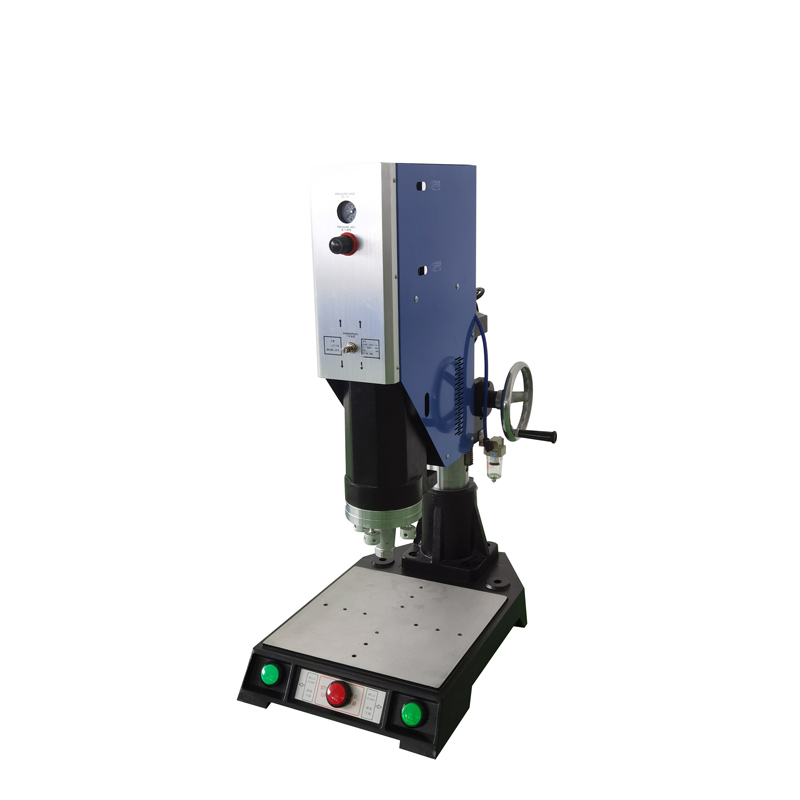

The characteristics of industrial ultrasonic plastic welding machine:

The characteristics of industrial ultrasonic plastic welding machine:

1. Efficient and energy-saving: The industrial ultrasonic plastic welding machine adopts the principle of high-frequency vibration, with fast welding speed and high production efficiency. Meanwhile, due to the absence of heating elements during the welding process, it has low energy consumption and is energy-saving and environmentally friendly.

2. High welding quality: During ultrasonic welding, plastic materials generate frictional heat at the contact surface, which melts and forms a whole. The welding strength is high, and it is not easy to deform and crack. In addition, the welding process does not require the addition of any auxiliary materials, ensuring the stability of welding quality.

3. Wide application range: Industrial ultrasonic plastic welding machine is suitable for welding various thermoplastic plastics, such as polyethylene, polypropylene, polyvinyl chloride, polycarbonate, stb. Meanwhile, due to the absence of heating elements during the welding process, effective welding can also be performed on some plastic materials that are not resistant to high temperatures, such as polyimide and polytetrafluoroethylene.

4. Easy to operate: The industrial ultrasonic plastic welding machine adopts microcomputer control, which has the characteristics of high automation, easy operation, and good stability. Operators only need to set welding parameters to achieve automated welding, reducing labor intensity and improving production efficiency.

Industrial ultrasonic plastic welding machine, as an efficient and environmentally friendly plastic processing equipment, has been widely used in various fields. With the continuous progress of technology and the expansion of the market, industrial ultrasonic plastic welding machines will play a more important role in the future.

| Típus | Hatalom(W) | Frekvencia (Khz) |

| PU-JGM1000W | 1000W | 15KHZ/20KHZ/40KHZ |

| PU-JGM2000W | 2000W | 15KHZ/20KHZ |

| PU-JGM3000W | 3000W | 15KHZ |

| PU-JGM4200W | 4200W | 15KHZ |

Ultrahangos jelátalakító,Ultrahangos generátor,Ultrahangos tisztító -SKSONIC

Ultrahangos jelátalakító,Ultrahangos generátor,Ultrahangos tisztító -SKSONIC