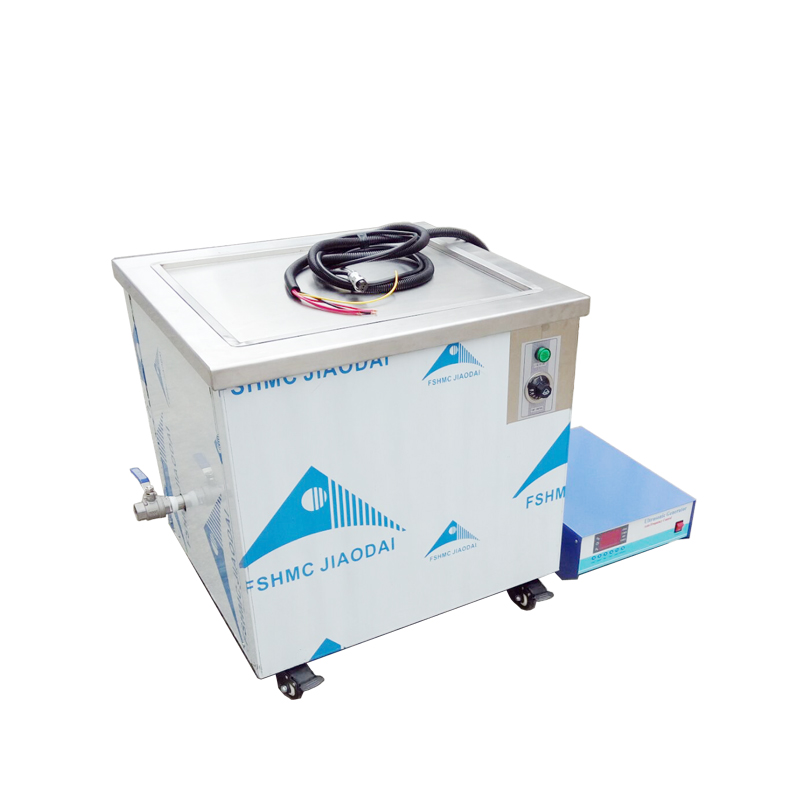

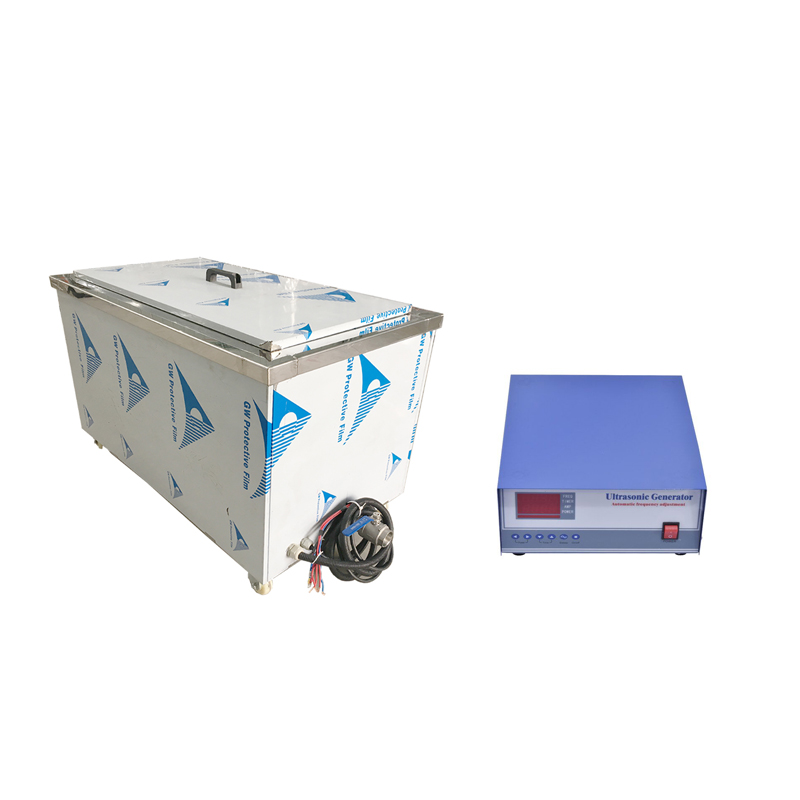

Ultrasonic cleaning machine is a cleaning tool widely used in the hardware industry, with a very clean cleaning effect. It is generally used for oil removal, rust removal, and rust prevention. For example, a large hardware parts manufacturer produces 30000 hardware parts per day, and manual cleaning is a particularly laborious task. Not only does it take a long time to clean, but the cleaning is not thorough enough, especially if the dirt in the gaps is not cleaned properly! If an ultrasonic cleaning machine is used, the efficiency of cleaning hardware parts is improved, and the oil and rust removal effect is cleaner.

Ultrasonic cleaning machine is a cleaning tool widely used in the hardware industry, with a very clean cleaning effect. It is generally used for oil removal, rust removal, and rust prevention. For example, a large hardware parts manufacturer produces 30000 hardware parts per day, and manual cleaning is a particularly laborious task. Not only does it take a long time to clean, but the cleaning is not thorough enough, especially if the dirt in the gaps is not cleaned properly! If an ultrasonic cleaning machine is used, the efficiency of cleaning hardware parts is improved, and the oil and rust removal effect is cleaner.

Ultrasonic cleaning and oil removal process:

1. Put oily hardware parts, aluminum blocks, metals, bearings, chains, molds, etc. into the cleaning basket and then put them into the cleaning tank

2. Add water and pour in a certain amount of degreaser

3. Press the switch and the ultrasonic cleaning machine starts working. After cleaning for a period of time, it is placed in another drying tank for drying. After drying for a period of time, the object and cleaning basket are taken out together.

4. Shut down and pay attention to maintenance

| Type | Internal size L*W*H(mm) |

Frequency(Khz) | Power(W) | Heating(W) |

| PU-1006TT | 280×210×210 | 20,28,33,40,80,130 | 300 | 1000 |

| PU-1012TT | 400×310×280 | 20,28,33,40,80,130 | 600 | 3000 |

| PU-1018TT | 490×360×320 | 20,28,33,40,80,130 | 900 | 3000 |

| PU-1024TT | 630×430×320 | 20,28,33,40,80,130 | 1200 | 4000 |

| PU-1030TT | 630×530×320 | 20,28,33,40,80,130 | 1500 | 4000 |

| PU-1036TT | 680×530×360 | 20,28,33,40,80,130 | 1800 | 5000 |

| PU-1040TT | 680×570×400 | 20,28,33,40,80,130 | 2000 | 5000 |

| PU-1041TT | 730×570×450 | 20,28,33,40,80,130 | 2400 | 6000 |

| PU-1042TT | 790×670×510 | 20,28,33,40,80,130 | 3000 | 6000 |

| PU-1043TT | 850×770×570 | 20,28,33,40,80,130 | 4000 | 7000 |

| PU-1044ST | 910×820×620 | 20,28,33,40,80,130 | 5000 | 7000 |

| PU-1045TT | 960×870×680 | 20,28,33,40,80,130 | 8000 | 8000 |

| PU-1046TT | 1100×930×730 | 20,28,33,40,80,130 | 10000 | 8000 |