Avec le développement continu de la technologie, people have increasingly high requirements for cleanliness in production and life, which has also promoted the development of fully automatic ultrasonic cleaning equipment. As an efficient cleaning equipment, the fully automatic ultrasonic cleaning equipment mainly utilizes the cavitation effect of ultrasonic waves in liquids to clean stains, oil stains, impurities, etc. on the surface of objects. Compared to traditional cleaning methods, fully automatic ultrasonic cleaning equipment has advantages such as good cleaning effect, high efficiency, and simple operation, so it has been widely used in many fields.

Avec le développement continu de la technologie, people have increasingly high requirements for cleanliness in production and life, which has also promoted the development of fully automatic ultrasonic cleaning equipment. As an efficient cleaning equipment, the fully automatic ultrasonic cleaning equipment mainly utilizes the cavitation effect of ultrasonic waves in liquids to clean stains, oil stains, impurities, etc. on the surface of objects. Compared to traditional cleaning methods, fully automatic ultrasonic cleaning equipment has advantages such as good cleaning effect, high efficiency, and simple operation, so it has been widely used in many fields.

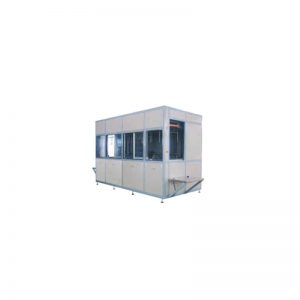

The fully automatic ultrasonic cleaning equipment mainly consists of an ultrasonic generator, ultrasonic cleaning tank, mechanical conveyor belt, circulating filtration system, heating system, blow drying system, etc. Among them, the ultrasonic generator is a component that generates ultrasonic waves. It generates high-frequency oscillations through a certain frequency of current, and then converts these oscillations into mechanical vibrations through a transducer, thereby generating ultrasonic waves in the cleaning solution. Ultrasonic cleaning tank is a container for storing cleaning solution, which can withstand certain pressure and temperature. The mechanical conveyor belt can send the workpiece to be cleaned into the cleaning tank for cleaning, and can send the workpiece out after cleaning is completed. The circulating filtration system can continuously filter out impurities and particles in the cleaning solution, maintaining its cleanliness and clarity. The heating system can heat the cleaning solution, improving the cleaning effect and efficiency. The drying system can blow dry the moisture on the surface of the workpiece after cleaning, making it convenient for subsequent operation and use.

Transducteur à ultrasons,Générateur d’ultrasons,Nettoyeur à ultrasons -SKSONIC

Transducteur à ultrasons,Générateur d’ultrasons,Nettoyeur à ultrasons -SKSONIC