Industrial ultrasonic plastic welding machines play an important role in modern manufacturing. This welding technique utilizes high-frequency vibration to precisely weld two or more plastic components together without the need for any adhesive or hot flux. Due to its high efficiency, environmental friendliness, and precision, ultrasonic plastic welding machines have been widely used in various fields such as automobiles, electronics, medical devices, and packaging.

Industrial ultrasonic plastic welding machines play an important role in modern manufacturing. This welding technique utilizes high-frequency vibration to precisely weld two or more plastic components together without the need for any adhesive or hot flux. Due to its high efficiency, environmental friendliness, and precision, ultrasonic plastic welding machines have been widely used in various fields such as automobiles, electronics, medical devices, and packaging.

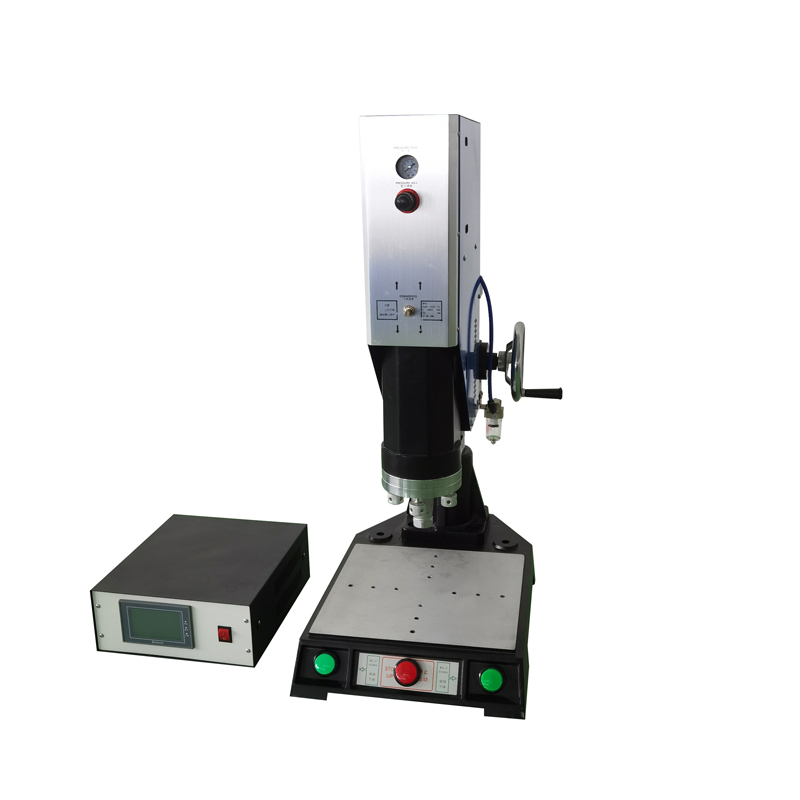

The working principle of industrial ultrasonic plastic welding machine is to convert high-frequency electrical energy into mechanical vibration through a transducer, which is transmitted to the working welding head, and then the ultrasonic energy is transmitted to the plastic parts to be welded through the contact surface. Under appropriate pressure, the contact surface of plastic parts generates heat due to ultrasonic friction, causing local melting of the plastic and forming intermolecular bonding, achieving the purpose of welding.

| Mataqali | Power(W) | iTuvatuva (KHz) |

| PU-JGM1000W | 1000W | 15KHZ/20KHZ/40KHZ |

| PU-JGM2000W | 2000W | 15KHZ/20KHZ |

| PU-JGM3000W | 3000W | 15KHZ |

| PU-JGM4200W | 4200W | 15KHZ |

Ultrasonic Transducer,Ultrasonic Generator,Ultrasonic Cleaner-SKSONIC

Ultrasonic Transducer,Ultrasonic Generator,Ultrasonic Cleaner-SKSONIC