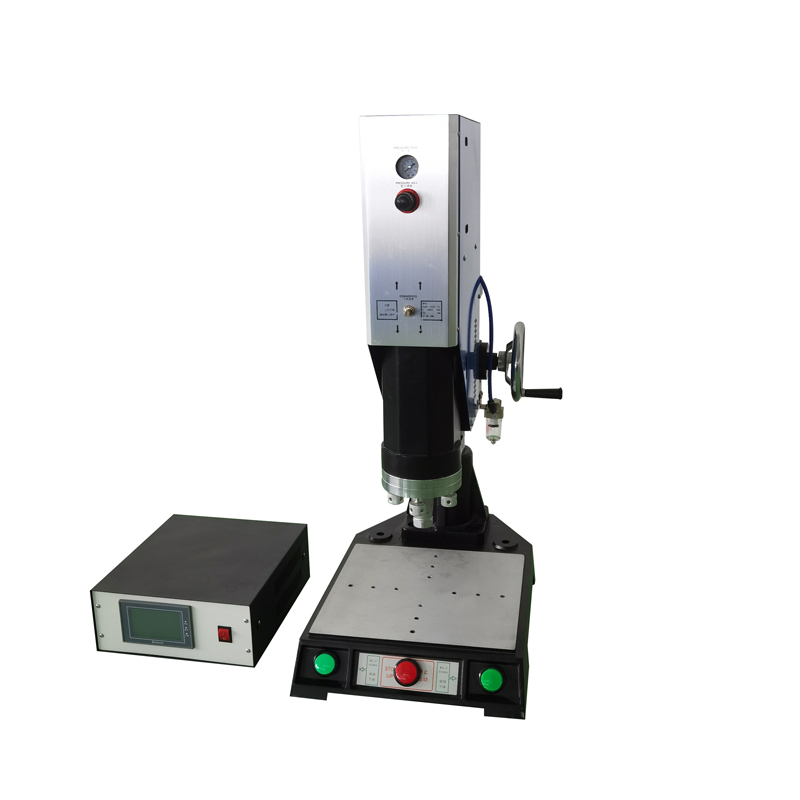

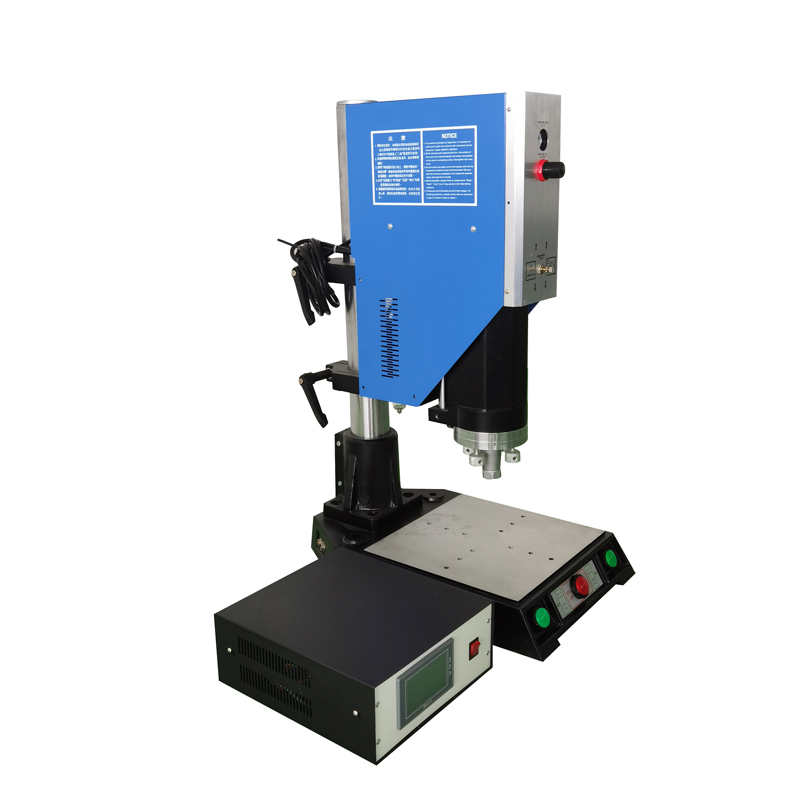

Industrial ultrasonic plastic welding machine is an efficient and accurate plastic processing equipment widely used in the production of various plastic products. Its working principle is to use the energy generated by ultrasonic vibration to generate frictional heat on the contact surface of plastic materials, thereby achieving material fusion. Compared to traditional hot melt welding and adhesive bonding methods, industrial ultrasonic plastic welding machines have many unique advantages.

Industrial ultrasonic plastic welding machine is an efficient and accurate plastic processing equipment widely used in the production of various plastic products. Its working principle is to use the energy generated by ultrasonic vibration to generate frictional heat on the contact surface of plastic materials, thereby achieving material fusion. Compared to traditional hot melt welding and adhesive bonding methods, industrial ultrasonic plastic welding machines have many unique advantages.

Industrial ultrasonic plastic welding machine has fast welding speed and high efficiency. Due to its unique welding principle, it can complete a large amount of welding work in a short time, greatly improving production efficiency. Samantala, as there is no need to add any adhesive or solvent during the welding process, it avoids the solvent residue and environmental pollution problems that may occur in traditional welding methods.

| Uri ng | Kapangyarihan(W) | Dalas (KHz) |

| PU-JGM1000W | 1000W | 15KHZ/20KHZ/40KHZ |

| PU-JGM2000W | 2000W | 15KHZ/20KHZ |

| PU-JGM3000W | 3000W | 15KHZ |

| PU-JGM4200W | 4200W | 15KHZ |

Ultrasonic Transducer,Ultrasonic Generator,Ultrasonic Cleaner -SKSONIC

Ultrasonic Transducer,Ultrasonic Generator,Ultrasonic Cleaner -SKSONIC