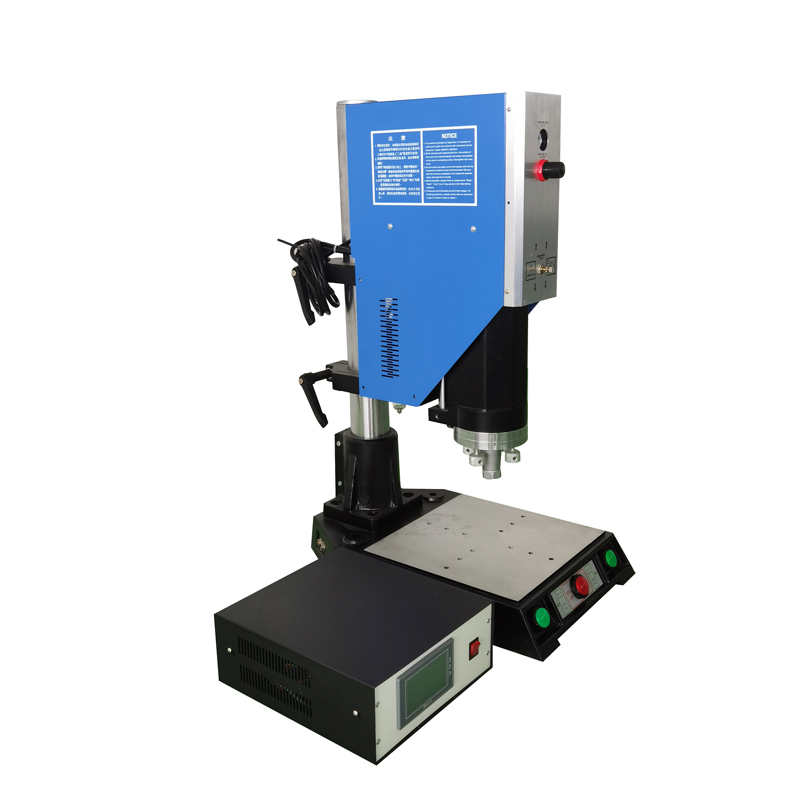

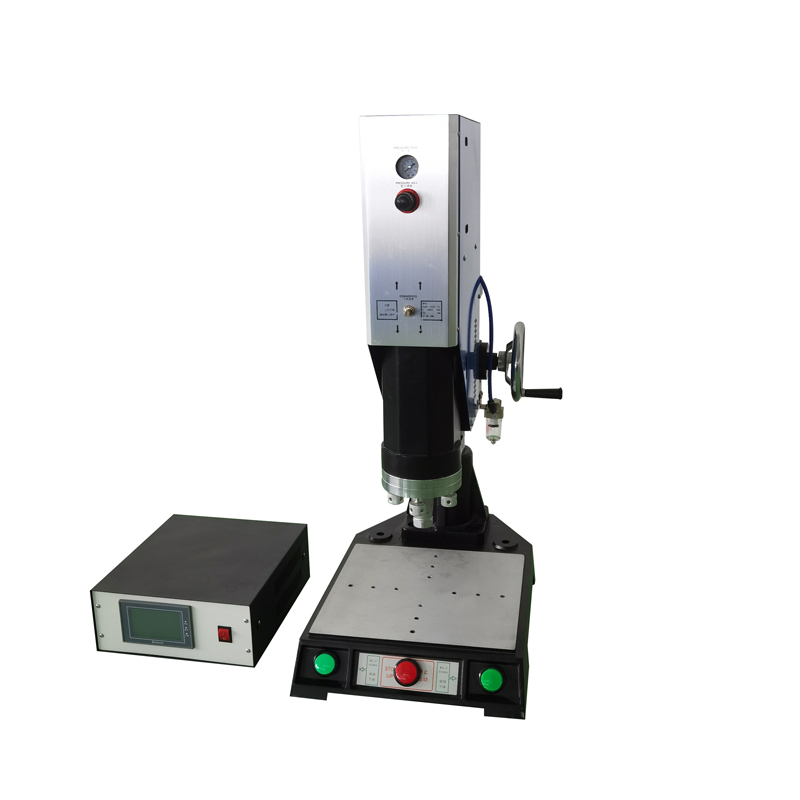

In industrial production, industrial ultrasonic plastic welding machines are widely used in fields such as automobiles, electronics, medical devices, packaging, etc. For example, in automobile manufacturing, it can be used to weld automotive interior parts, body parts, etc; In the field of electronics, it can be used for soldering electronic components, circuit boards, etc; In the field of medical devices, it can be used to manufacture various precision medical and surgical instruments.

In industrial production, industrial ultrasonic plastic welding machines are widely used in fields such as automobiles, electronics, medical devices, packaging, etc. For example, in automobile manufacturing, it can be used to weld automotive interior parts, body parts, etc; In the field of electronics, it can be used for soldering electronic components, circuit boards, etc; In the field of medical devices, it can be used to manufacture various precision medical and surgical instruments.

Although industrial ultrasonic plastic welding machines have many advantages, there are still some issues that need to be noted in practical applications. Firstly, there may be compatibility issues with plastics of different materials during the welding process, which require selection and adjustment based on specific circumstances. Secondly, the maintenance and upkeep of the equipment is also very important, requiring regular cleaning and inspection to ensure the normal operation of the equipment and extend its service life. In order to better leverage the advantages of industrial ultrasonic plastic welding machines and improve their application effectiveness, we can take the following measures. Firstly, strengthen the training and education of equipment operators to enhance their operational skills and safety awareness. Secondly, strengthen communication and cooperation with material suppliers, understand the properties and characteristics of materials, and select materials suitable for welding. In addition, equipment can be improved and optimized according to specific production needs to enhance its adaptability and flexibility.

| Liik | Võimsus(W) | Sagedus (Khz) |

| PU-JGM1000W | 1000W | 15KHZ/20KHZ/40KHZ |

| PU-JGM2000W | 2000W | 15KHZ/20KHZ |

| PU-JGM3000W | 3000W | 15KHZ |

| PU-JGM4200W | 4200W | 15KHZ |

Ultraheli andur,Ultraheli generaator,Ultraheli puhastaja -SKSONIC

Ultraheli andur,Ultraheli generaator,Ultraheli puhastaja -SKSONIC