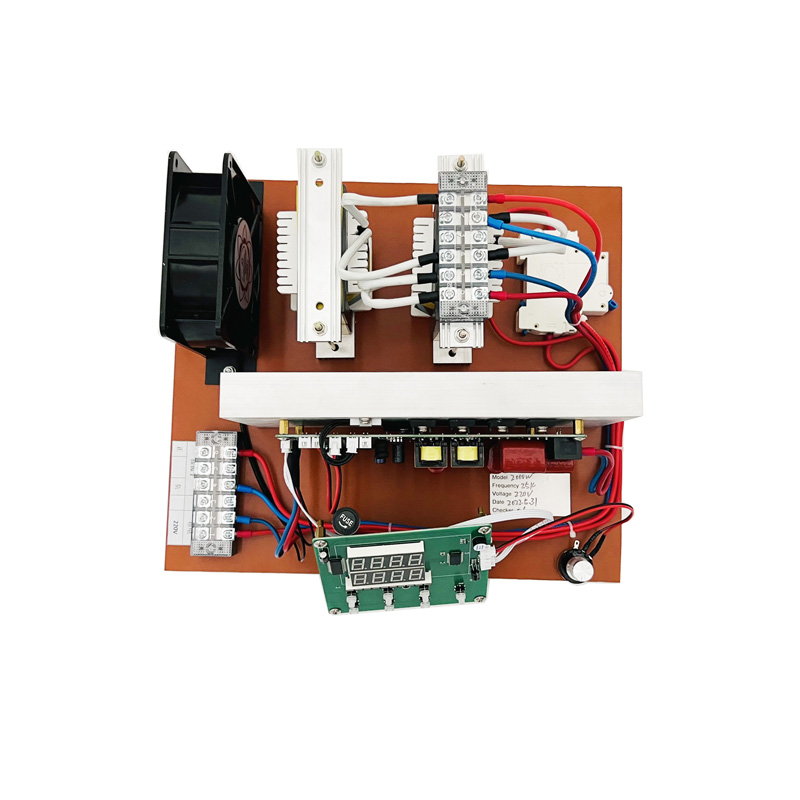

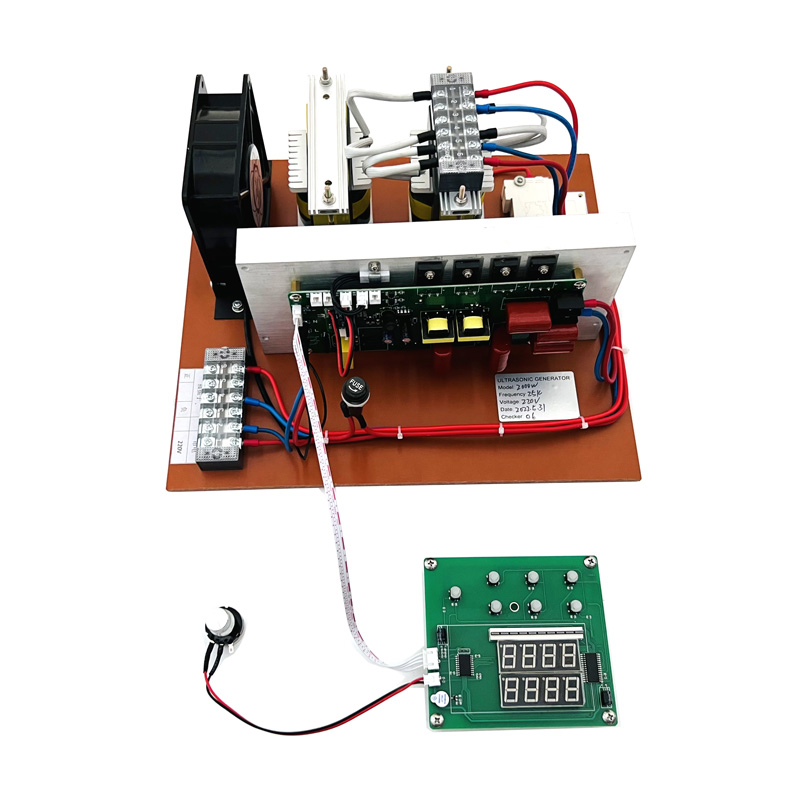

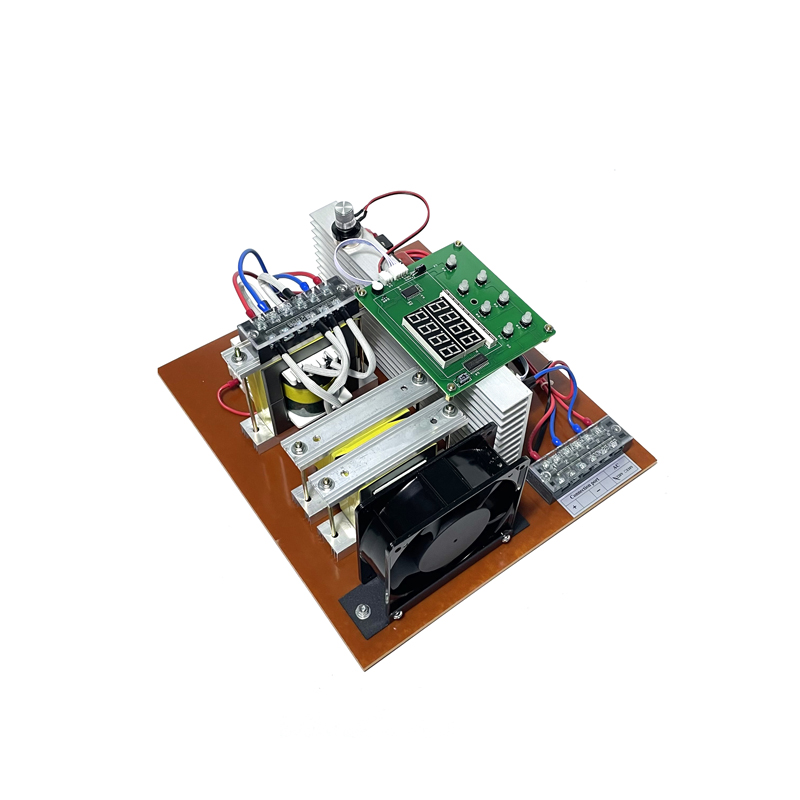

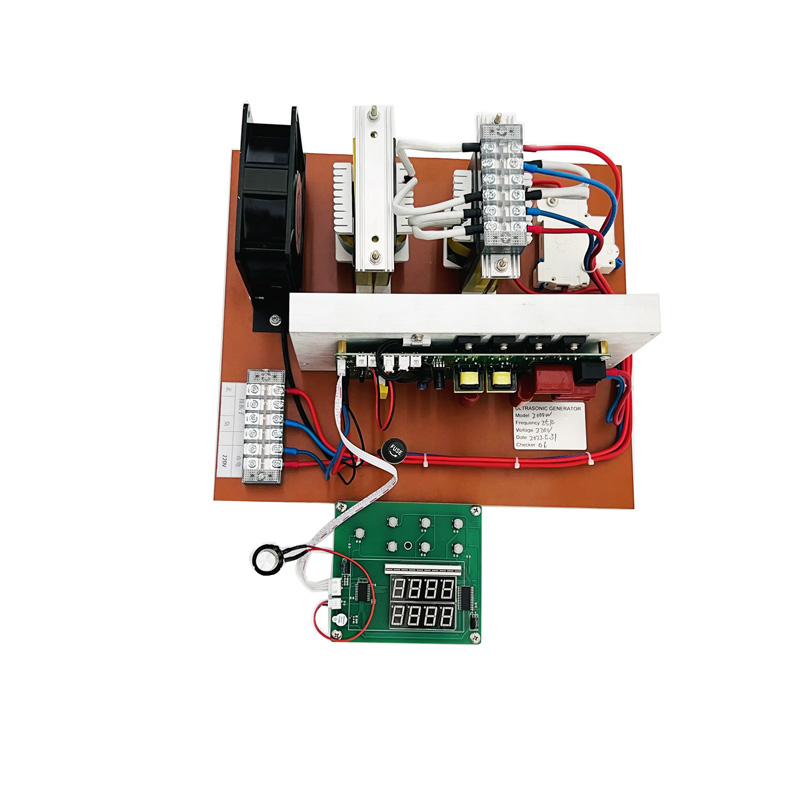

The industrial ultrasonic circuit board adopts digital control technology to apply automatic frequency scanning technology to the hysteresis ultrasonic power supply equipment, and provides an external software interface for users to set the three parameters of automatic scanning according to actual usage needs. The industrial ultrasonic circuit board searches for the most suitable power supply working frequency by changing the working frequency of the external DC power supply to add DC energy to the hysteresis ultrasonic material, To improve the working frequency and ultrasonic cleaning effect of ultrasonic materials

The industrial ultrasonic circuit board adopts digital control technology to apply automatic frequency scanning technology to the hysteresis ultrasonic power supply equipment, and provides an external software interface for users to set the three parameters of automatic scanning according to actual usage needs. The industrial ultrasonic circuit board searches for the most suitable power supply working frequency by changing the working frequency of the external DC power supply to add DC energy to the hysteresis ultrasonic material, To improve the working frequency and ultrasonic cleaning effect of ultrasonic materials

The industrial ultrasonic circuit board allows users to easily set different parameters for automatic frequency scanning according to specific environments. The digital control system uses TI’s TMS320F28335 chip, and the external FLASH chip is used to store the required frequency data, making it very convenient to achieve various timing and frequency setting functions

The industrial ultrasonic circuit board achieves frequency tracking and power regulation control, improving the real-time performance of the system. Here, a full bridge inverter is used as the power conversion main circuit of the ultrasonic vibration system to solve the drift of resonance frequency caused by load temperature changes and other reasons, ensuring the high efficiency of the system. A frequency tracking scheme with coarse and fine combination is studied, and a frequency scanning method is used to achieve frequency coarse tracking, The hardware phase-locked loop is used to achieve precise tracking. The combination of these two methods not only ensures automatic frequency tracking within a wide range of frequency changes, but also ensures fast and accurate tracking. To adapt to the requirements of load changes, a soft switching PS-PWM control method is used to continuously adjust the output power of the system

| Type | Power(W) | Frequency (KHz) |

| PU-DGPCB300W | 300 | 20khz,25khz,28khz,33khz,40khz Frequency is adjustable |

| PU-DGPCB600W | 600 | 20khz,25khz,28khz,33khz,40khz Frequency is adjustable |

| PU-DGPCB900W | 900 | 20khz,25khz,28khz,33khz,40khz Frequency is adjustable |

| PU-DGPCB1000W | 1000 | 20khz,25khz,28khz,33khz,40khz Frequency is adjustable |

| PU-DGPCB1200W | 1200 | 20khz,25khz,28khz,33khz,40khz Frequency is adjustable |

| UCE-HPPCB1500W | 1500 | 20khz,25khz,28khz,33khz,40khz Frequency is adjustable |

| PU-DGPCB1800W | 1800 | 20khz,25khz,28khz,33khz,40khz Frequency is adjustable |

| PU-DGPCB2000W | 2000 | 20khz,25khz,28khz,33khz,40khz Frequency is adjustable |

| PU-DGPCB2400W | 2400 | 20khz,25khz,28khz,33khz,40khz Frequency is adjustable |

| PU-DGPCB3000W | 3000 | 20khz,25khz,28khz,33khz,40khz Frequency is adjustable |

Transductor ultrasónico,Generador ultrasónico,Limpiador ultrasónico -SKSONIC

Transductor ultrasónico,Generador ultrasónico,Limpiador ultrasónico -SKSONIC