The working principle of high-frequency ultrasonic cleaning transducers mainly utilizes the piezoelectric effect and inverse piezoelectric effect to convert electrical energy into mechanical energy, thereby generating high-frequency vibration. When the transducer is in operation, an external power source charges the capacitor. After charging, a potential difference is formed between the two plates of the capacitor, causing the electric field between the plates to strengthen and forming electric field energy. As the charging time increases, the electric field energy also increases, and the electric field between the plates also increases, causing discharge between the plates. After discharge, the potential difference between the two plates of the capacitor decreases, the electric field strength weakens, and the discharge between the plates stops. This process is repeated, and alternating current is formed at both ends of the capacitor. Due to the inverse piezoelectric effect, piezoelectric crystals generate high-frequency vibrations under the action of high-frequency alternating electric fields. This vibration is transmitted to the cleaning solution in the cleaning tank, forming high-frequency radiating water marks. The water marks continuously impact the surface of the workpiece to be cleaned, causing various dirt on the surface of the workpiece to quickly fall off.

The working principle of high-frequency ultrasonic cleaning transducers mainly utilizes the piezoelectric effect and inverse piezoelectric effect to convert electrical energy into mechanical energy, thereby generating high-frequency vibration. When the transducer is in operation, an external power source charges the capacitor. After charging, a potential difference is formed between the two plates of the capacitor, causing the electric field between the plates to strengthen and forming electric field energy. As the charging time increases, the electric field energy also increases, and the electric field between the plates also increases, causing discharge between the plates. After discharge, the potential difference between the two plates of the capacitor decreases, the electric field strength weakens, and the discharge between the plates stops. This process is repeated, and alternating current is formed at both ends of the capacitor. Due to the inverse piezoelectric effect, piezoelectric crystals generate high-frequency vibrations under the action of high-frequency alternating electric fields. This vibration is transmitted to the cleaning solution in the cleaning tank, forming high-frequency radiating water marks. The water marks continuously impact the surface of the workpiece to be cleaned, causing various dirt on the surface of the workpiece to quickly fall off.

| Δακτυλογραφώ | Length(mm) | Weight(g) | Frequency(KHz) | Resonance Impedance (Ω) |

Static Capacity (pF)±10% |

Input Power(W) |

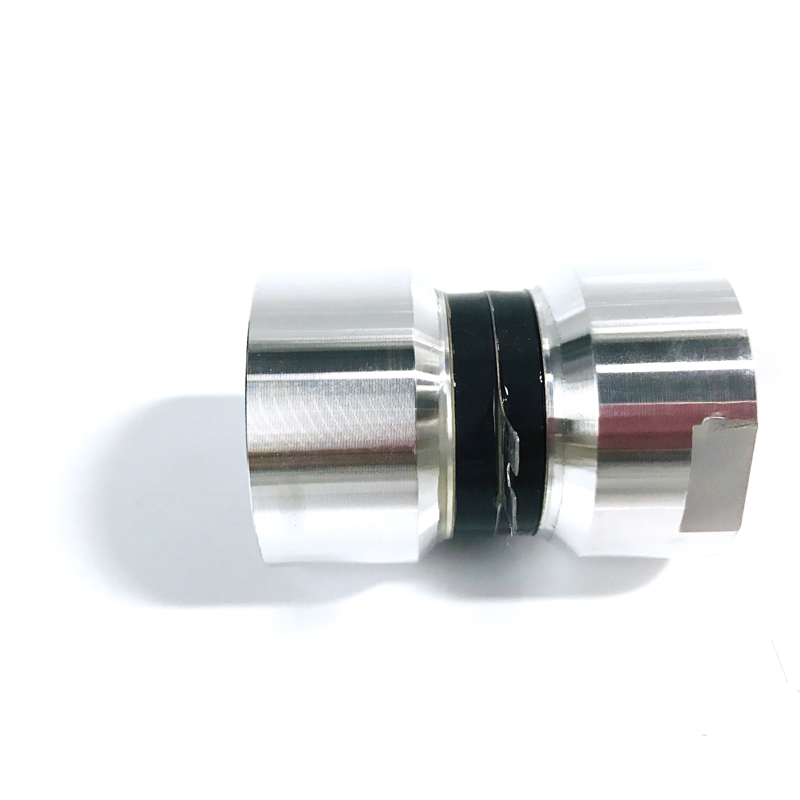

| PU-UT-5435 PZT-4 |

36 | 135 | 54 | 10-20 | 3200 | 35 |

| PU-UT-6860 PZT-8 |

80 | 460 | 68 | 10-20 | 3800 | 60 |

| PU-UT-68120 PZT-4 |

67 | 588 | 68 | 10-20 | 7800 | 120 |

| PU-UT-8060 PZT-4 |

60 | 325 | 80 | 10-20 | 5400 | 60 |

| PU-UT-12060 PZT-4 |

56 | 260 | 120 | 10-20 | 5400 | 60 |

| PU-UT-13550 PZT-4 |

54 | 215 | 135 | 10-20 | 4200 | 50 |

Μετατροπέας υπερήχων,Γεννήτρια υπερήχων,Καθαριστικό υπερήχων -SKSONIC

Μετατροπέας υπερήχων,Γεννήτρια υπερήχων,Καθαριστικό υπερήχων -SKSONIC