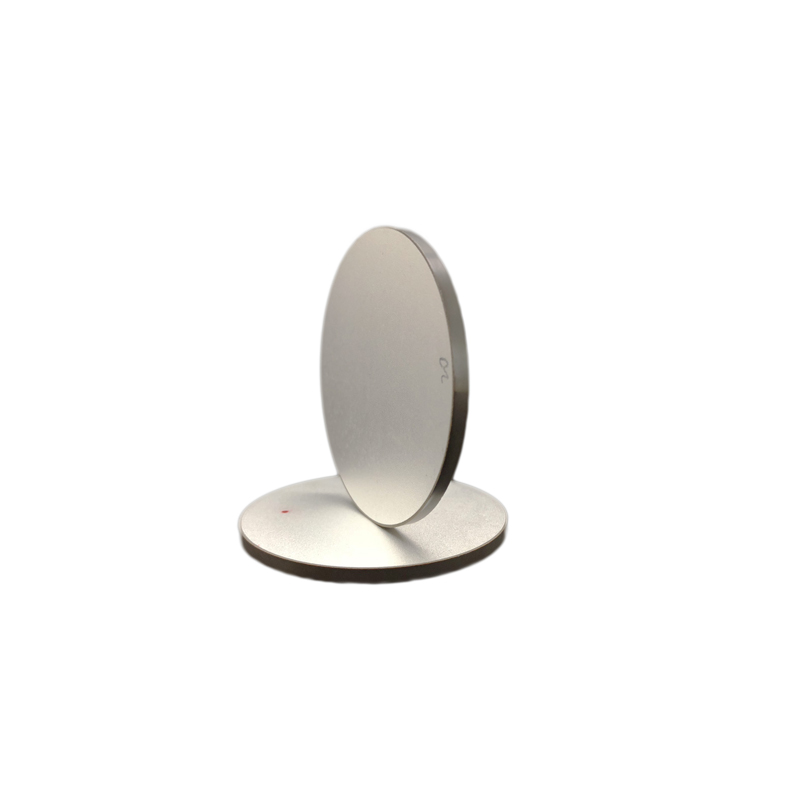

The main characteristic of piezoelectric ceramic chips is their piezoelectric effect, which means they can generate charges or voltages under mechanical stress, or undergo mechanical deformation under the action of electrical signals. In addition, piezoelectric ceramic chips also have good insulation, stability, and reliability, and can work normally in harsh environments such as high temperature, low temperature, high humidity, and high vacuum.

The main characteristic of piezoelectric ceramic chips is their piezoelectric effect, which means they can generate charges or voltages under mechanical stress, or undergo mechanical deformation under the action of electrical signals. In addition, piezoelectric ceramic chips also have good insulation, stability, and reliability, and can work normally in harsh environments such as high temperature, low temperature, high humidity, and high vacuum.

The application of piezoelectric ceramic chips is very extensive, such as in sensors, transducers, filters, etc. In terms of sensors, piezoelectric ceramic chips can be used to measure physical quantities such as pressure, acceleration, and vibration. In terms of transducers, piezoelectric ceramic chips can be used to convert electrical energy into mechanical energy, such as ultrasonic generators. In terms of filters, piezoelectric ceramic chips can be used for frequency control and screening in signal processing and communication systems.

| Specification | Dimension (Mm) |

Radial frequency (Khz) |

Capacitance (±12.5%) pf |

Dielectric dissipation factortanδ (%) |

Impedance (Ω) |

Electromechanical coupling coefficientKr | Mechanical quality factor (Qm) |

| PLS-QXJP3030 | Φ30×3.0 | 66.7 | 2730 | ≤0.3 | ≤15 | ≥0.55 | 500 |

| PLS-QXJP3530 | Φ35×3.0 | 63 | 3100 | ≤0.3 | ≤15 | ≥0.55 | 500 |

| PLS-QXJP3865 | Φ38×6.5 | 59.9 | 1580 | ≤0.3 | ≤15 | ≥0.55 | 500 |

| PLS-QXJP4530 | Φ45×3.0 | 50 | 5100 | ≤0.3 | ≤15 | ≥0.55 | 500 |

| PLS-QXJP4535 | Φ45×3.5 | 50 | 4700 | ≤0.3 | ≤15 | ≥0.55 | 500 |

| PLS-QXJP5030 | Φ50×3.0 | 46 | 5800 | ≤0.3 | ≤15 | ≥0.55 | 500 |

| PLS-QXJP5035 | Φ50×3.5 | 46 | 6300 | ≤0.3 | ≤15 | ≥0.55 | 500 |

| PLS-QXJP5050 | Φ50×5.0 | 46 | 4150 | ≤0.3 | ≤15 | ≥0.55 | 500 |

Ultraschall-Wandler,Ultraschall-Generator,Ultraschall-Reiniger -SKSONIC

Ultraschall-Wandler,Ultraschall-Generator,Ultraschall-Reiniger -SKSONIC