The welding surface of the plastic ultrasonic welding machine equipment surrounding the connection interface must be unified and closely connected with each other. If possible, the contact surface should be on the same plane as much as possible, so as to maintain consistency during energy conversion. Close range welding refers to the welding position being within 6mm from the contact position of the welding head, while long-distance welding is greater than 6mm. The energy in ultrasonic welding is attenuated during the transmission of plastic parts. Attenuation is also severe in low hard bottom plastics, so special attention should be paid to allowing sufficient energy to be transmitted to the processing area during design. Long distance welding is suitable for hard adhesives such as PS, ABS, AS, PMMA, ayyb. Some semi crystalline plastics (such as POM, PETP, PBTB, PA) can also be used for long-distance welding through appropriate shape design.

The welding surface of the plastic ultrasonic welding machine equipment surrounding the connection interface must be unified and closely connected with each other. If possible, the contact surface should be on the same plane as much as possible, so as to maintain consistency during energy conversion. Close range welding refers to the welding position being within 6mm from the contact position of the welding head, while long-distance welding is greater than 6mm. The energy in ultrasonic welding is attenuated during the transmission of plastic parts. Attenuation is also severe in low hard bottom plastics, so special attention should be paid to allowing sufficient energy to be transmitted to the processing area during design. Long distance welding is suitable for hard adhesives such as PS, ABS, AS, PMMA, ayyb. Some semi crystalline plastics (such as POM, PETP, PBTB, PA) can also be used for long-distance welding through appropriate shape design.

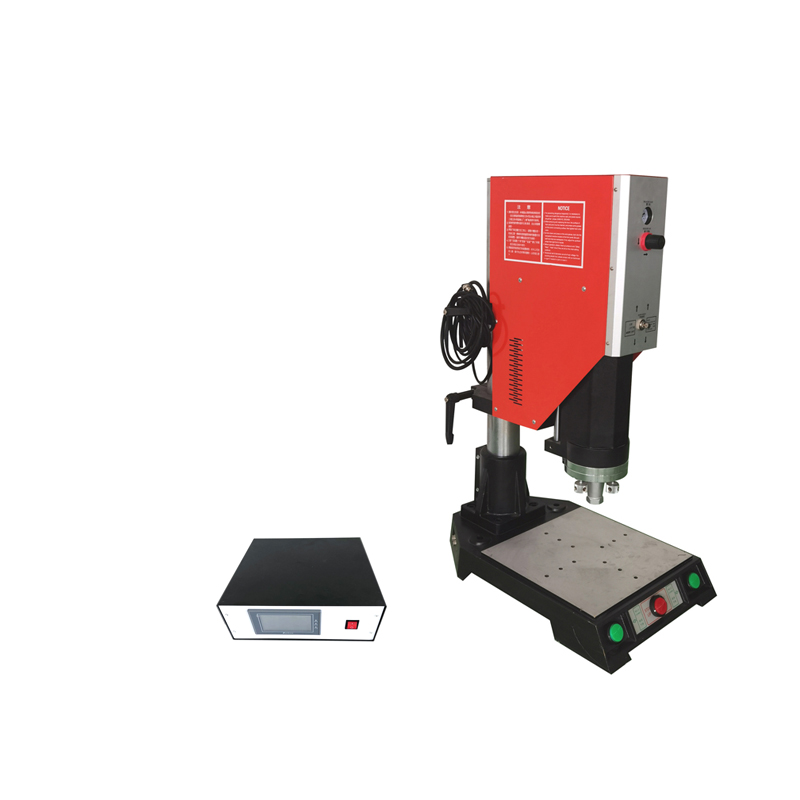

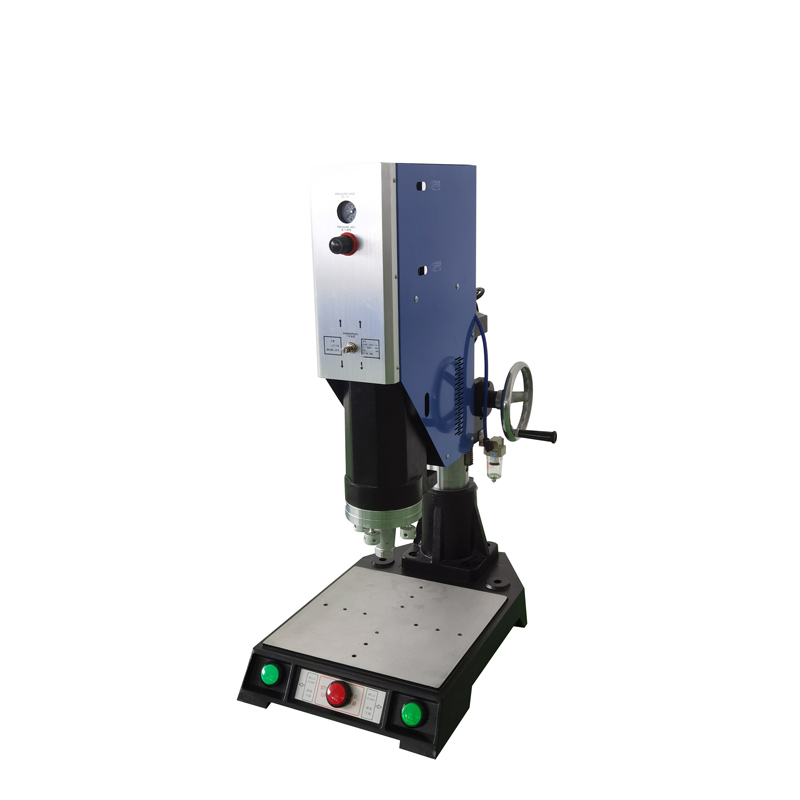

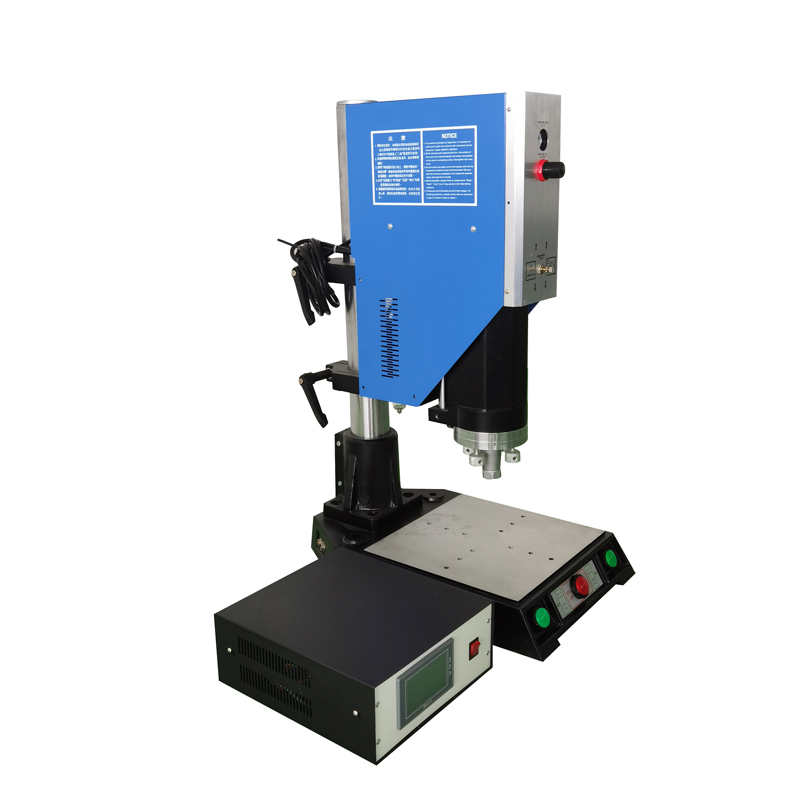

| Type | Pŵer(W) | Frequency (KHz) |

| PU-JGM1000W | 1000W | 15KHZ/20KHZ/40KHZ |

| PU-JGM2000W | 2000W | 15KHZ/20KHZ |

| PU-JGM3000W | 3000W | 15KHZ |

| PU-JGM4200W | 4200W | 15KHZ |

Ultrasonic Transducer,Generadur ultrasonic,Glanhawr ultrasonic -SKSONIC

Ultrasonic Transducer,Generadur ultrasonic,Glanhawr ultrasonic -SKSONIC