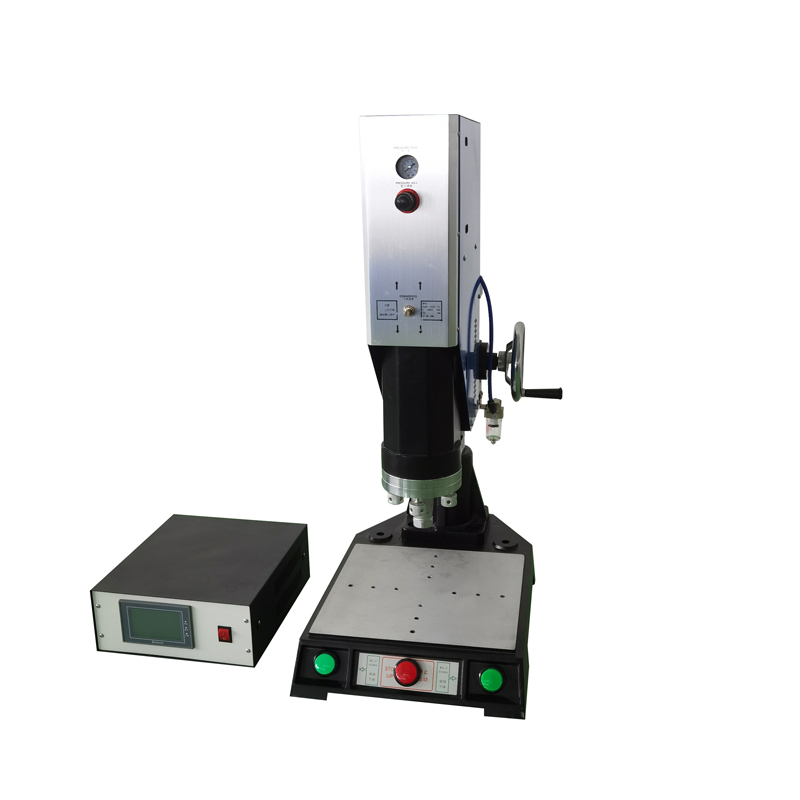

Ultrasonic welding machine equipment has significant advantages such as high production efficiency, good welding quality, environmental protection, and energy conservation. There are also significant technical differences between the selected ultrasonic and welding equipment, which require corresponding usage scenarios to determine the power size and frequency. Plastic parts must have a certain degree of rigidity and sufficient wall thickness. If the wall thickness is too thin, there is a certain risk. During ultrasonic welding, pressure is required, with a general air pressure of 2-6kgf/cm2. So plastic parts must ensure basic deformation under pressure.

Ultrasonic welding machine equipment has significant advantages such as high production efficiency, good welding quality, environmental protection, and energy conservation. There are also significant technical differences between the selected ultrasonic and welding equipment, which require corresponding usage scenarios to determine the power size and frequency. Plastic parts must have a certain degree of rigidity and sufficient wall thickness. If the wall thickness is too thin, there is a certain risk. During ultrasonic welding, pressure is required, with a general air pressure of 2-6kgf/cm2. So plastic parts must ensure basic deformation under pressure.

| Typ | Moc(W) | Frekvence (Kiloherth) |

| PU-JGM1000W | 1000W | 15KHZ/20KHZ/40KHZ |

| PU-JGM2000W | 2000W | 15KHZ/20KHZ |

| PU-JGM3000W | 3000W | 15KHZ |

| PU-JGM4200W | 4200W | 15KHZ |

Ultrazvukový měnič,Ultrazvukový generátor,Ultrazvuková čistička -SKSONIC

Ultrazvukový měnič,Ultrazvukový generátor,Ultrazvuková čistička -SKSONIC