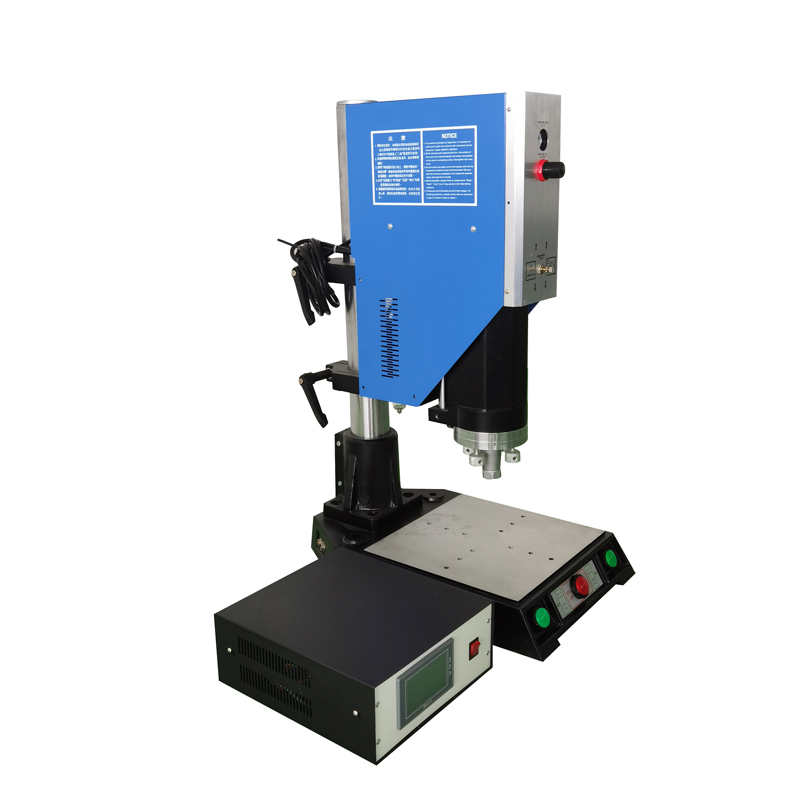

The characteristics of industrial ultrasonic plastic welding machine:

The characteristics of industrial ultrasonic plastic welding machine:

1. Efficient and energy-saving: During ultrasonic welding, energy directly acts on the contact surface of the workpiece, resulting in low heat loss and fast welding speed, thus having high energy utilization efficiency.

2. Environmentally friendly and pollution-free: Ultrasonic welding does not require the addition of any adhesives or solvents, avoiding pollutants such as exhaust gas and wastewater that may be generated during traditional welding processes.

3. High welding strength: Ultrasonic welding achieves connection by melting the plastic contact surface, with high welding strength and high reliability and stability.

4. Wide application range: Industrial ultrasonic plastic welding machine is suitable for welding various thermoplastic plastics, such as polyethylene, polypropylene, polyvinyl chloride, etc.

5. Easy to operate: Ultrasonic welding equipment has a compact structure, simple operation, and is easy to achieve automated production.

Industrial ultrasonic plastic welding machine, as an efficient and environmentally friendly plastic connection technology, has broad application prospects and development space. With the continuous progress and innovation of technology, it is believed that it will play an important role in more fields, bringing more convenience and well-being to human production and life.

| Typ | Moc(W) | Frekvence (Kiloherth) |

| PU-JGM1000W | 1000W | 15KHZ/20KHZ/40KHZ |

| PU-JGM2000W | 2000W | 15KHZ/20KHZ |

| PU-JGM3000W | 3000W | 15KHZ |

| PU-JGM4200W | 4200W | 15KHZ |

Ultrazvukový měnič,Ultrazvukový generátor,Ultrazvuková čistička -SKSONIC

Ultrazvukový měnič,Ultrazvukový generátor,Ultrazvuková čistička -SKSONIC